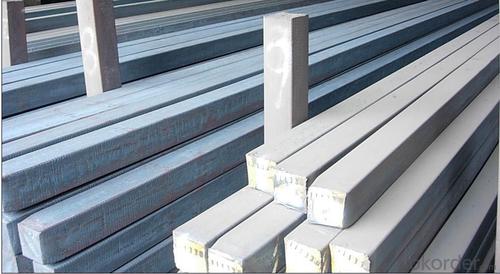

Prime square alloy steel billet 120mm Q235

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime square alloy steel billet 120mm Q235

Description of Prime square alloy steel billet 120mm Q235

Manufacture Progress:HRC-CRC-GALVANIZED-COLOR COATED

Application : Construction, electrical, transportation, steel plant, composite board plant, steel tile factory

Payment & Shipping Terms:T/T ,L/C, and FOB CHINA

Minimum Order Quantity: 25Tons

Packge Type: Moisture-proof paper inner,Steel outside,Bundle by steel rope.

Package in Container : Wood as a foot pad, wire rope reinforcement,PPGI steel coil tied together by steel rope.

Main Feature of Prime square alloy steel billet 120mm Q235

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime square alloy steel billet 120mm Q235

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.

Specifications of Prime square alloy steel billet 120mm Q235

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime square alloy steel billet 120mm Q235

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

we always fix steel produce in container well to make it safe arrive at destination port

we always provide best and professional forward service for our buyer

we always apply 14days free detention for our buyers container in destination

we provide one set After-sales service for our buyer

we provide China inland steel market price report

we help our buyer become number one in local market .

- Q: What are the different methods of surface treatment for steel billets?

- Various methods exist for surface treatment of steel billets, each serving a distinct purpose and offering unique advantages. Among the most commonly employed techniques are: 1. Pickling: This involves immersing the steel billets in an acid solution to eliminate surface impurities like rust or scale. Pickling enhances surface finish and readies the steel for subsequent treatment or processing. 2. Shot blasting: In this method, high-speed steel shots or grits are used to bombard the steel billets, eliminating surface contaminants and creating a uniform texture. Shot blasting is frequently employed to remove rust, scale, or paint, and it can enhance the adhesion of subsequent coatings or paints. 3. Galvanizing: This treatment entails coating the steel billets with a layer of zinc to provide corrosion resistance. Galvanizing can be accomplished through hot-dip galvanizing, where the steel is immersed in a molten zinc bath, or through electroplating, where a thin layer of zinc is deposited on the surface using an electric current. 4. Painting or powder coating: Steel billets can be painted or coated with powder to deliver both aesthetic appeal and protection against corrosion. Paints or powder coatings create a barrier between the steel surface and the environment, preventing moisture and other corrosive agents from reaching the metal. 5. Passivation: This method requires treating the steel billets with a chemical solution, typically an acid, to remove any free iron or iron oxide from the surface. Passivation enhances the corrosion resistance of stainless steel and other alloys by creating a passive oxide layer that safeguards against further oxidation or rusting. 6. Nitriding: Nitriding is a surface hardening treatment where the steel billets are exposed to an atmosphere rich in nitrogen at elevated temperatures. This process diffuses nitrogen into the steel's surface, forming a hardened layer that enhances wear resistance and improves fatigue strength. 7. Chrome plating: Steel billets can be coated with a layer of chromium through electroplating, providing enhanced corrosion resistance and a glossy appearance. Chrome plating is frequently utilized in applications where aesthetics and durability are crucial, such as automotive parts or decorative fixtures. These examples represent only a fraction of the available surface treatment methods for steel billets. The selection of a particular technique depends on factors such as the desired outcome, the specific properties required, and the intended application of the steel billets.

- Q: What are the different types of steel billet rolling processes?

- There are several types of steel billet rolling processes, including hot rolling, cold rolling, and warm rolling. Hot rolling involves heating the billet to a high temperature and then passing it through a series of rollers to shape it into the desired form. Cold rolling, on the other hand, is performed at room temperature and involves passing the billet through rollers to achieve a desired thickness or shape. Warm rolling is a combination of hot and cold rolling, where the billet is heated to a lower temperature compared to hot rolling but higher than room temperature. Each of these processes has its own advantages and is used for different applications in the steel industry.

- Q: What is the typical composition of steel billets?

- The composition of steel billets can vary depending on specific requirements and intended use, resulting in a typical composition that primarily consists of iron and carbon. Other elements are added to enhance certain properties. The carbon content in steel billets typically ranges from 0.1% to 0.3%. Besides iron and carbon, steel billets often contain small amounts of manganese, silicon, sulfur, and phosphorus. Manganese improves strength, hardness, and heat treatment response. Silicon is commonly added to enhance fluidity during casting. Sulfur and phosphorus are impurities that need to be minimized as they can adversely affect machinability and mechanical properties. Additionally, steel billets may contain alloying elements like chromium, nickel, molybdenum, and vanadium to impart specific properties. Chromium improves corrosion resistance, nickel enhances toughness and ductility, molybdenum increases high-temperature strength, and vanadium improves wear resistance. In summary, the composition of steel billets is carefully controlled to achieve desired mechanical, physical, and chemical properties required for subsequent processing and final applications of the steel.

- Q: What are the common uses of steel billets?

- Steel billets are commonly used in the production of various steel products such as bars, rods, wire, pipes, and structural components. They serve as the raw material for further processing and shaping, making them essential in industries like construction, manufacturing, and infrastructure development.

- Q: What are the main factors that influence the strength of steel billets?

- The strength of steel billets is impacted by various factors, including the chemical composition, heat treatment, and microstructure of the steel. The chemical composition plays a significant role in determining the strength of steel billets. Alloying elements like carbon, manganese, silicon, and chromium can enhance strength by forming solid solutions or precipitates that increase hardness and tensile strength. It is crucial to control impurity levels and maintain the desired balance of alloying elements to achieve the desired strength properties. Heat treatment is another important factor that affects the strength of steel billets. This process involves heating the steel to a specific temperature and then cooling it at a controlled rate. It significantly impacts the microstructure of the steel, which ultimately influences its strength. For example, quenching and tempering can result in the formation of desired microstructures like martensite or bainite, which enhance strength and toughness. The microstructure of steel billets also plays a crucial role in determining their strength. The arrangement of crystal grains and the presence of different phases within the steel greatly influence its mechanical properties. Fine-grained structures generally exhibit higher strength due to a greater number of grain boundaries, which inhibit dislocation movement and enhance strength. Additionally, the presence of specific microstructural features like precipitates or second-phase particles can contribute to the strength of steel billets. Other factors such as the manufacturing process, cooling rate during solidification, and mechanical working (such as rolling or extrusion) can also affect the strength of steel billets. These factors impact grain size, grain boundary density, and defect concentration, all of which influence the mechanical properties of the steel. In conclusion, the strength of steel billets is influenced by the chemical composition, heat treatment, and microstructure of the steel. These factors can be carefully controlled and optimized to achieve the desired strength properties for various applications.

- Q: What is the role of steel billets in the manufacturing of fasteners?

- Steel billets play a crucial role in the manufacturing of fasteners as they serve as the raw material from which fasteners are produced. These billets are heated, molded, and shaped into various forms such as bolts, screws, and nails. The high strength and durability of steel make it an ideal material for fasteners, ensuring that they can withstand the loads and stresses they are subjected to in various applications.

- Q: How are steel billets inspected for surface cleanliness?

- Steel billets are inspected for surface cleanliness through a series of visual and nondestructive testing methods. One of the commonly used techniques is visual inspection, where trained inspectors visually examine the surface of the billets for any visible impurities, such as scale, rust, dirt, or any other contaminants. This method helps identify any surface irregularities that may affect the quality of the billets. Additionally, nondestructive testing methods like magnetic particle inspection (MPI) and ultrasonic testing (UT) are employed to further evaluate the surface cleanliness of steel billets. Magnetic particle inspection involves applying a magnetic field to the billet's surface and then applying iron particles to it. If any surface cracks or defects are present, the iron particles will be attracted to these areas, making them visible to the inspector. Ultrasonic testing, on the other hand, uses high-frequency sound waves to detect any internal or surface defects. A probe is placed on the billet's surface, and sound waves are transmitted into the material. These waves are then reflected back to the probe and analyzed to identify any defects, such as inclusions or voids, which may affect the surface cleanliness. Overall, a combination of visual inspection, magnetic particle inspection, and ultrasonic testing is used to ensure that steel billets meet the required surface cleanliness standards. These inspection methods help identify any impurities or defects that could potentially compromise the quality and performance of the final steel product.

- Q: What are the potential applications of steel billets in the transportation sector?

- Due to their strength, durability, and versatility, steel billets offer a wide range of potential applications in the transportation sector. One primary use is in the manufacturing of various vehicle components, such as engine parts, suspension systems, axles, and other critical parts that require high strength and resistance to wear and tear. Moreover, steel billets can be utilized in the construction of railway tracks, bridges, and tunnels. With its high tensile strength, steel is an ideal material for infrastructure projects as it can withstand heavy loads and provide long-lasting performance. It is also suitable for manufacturing shipbuilding components like hulls, propellers, and deck structures, offering excellent corrosion resistance and structural integrity in marine environments. Additionally, steel billets find use in the production of transportation equipment like trailers, trucks, and buses. Its strength and durability make it an ideal material for constructing the chassis and frames of these vehicles, ensuring their safety and longevity. In the automotive industry, steel billets are commonly used for producing car bodies and frames. The lightweight yet robust characteristics of steel make it a preferred choice for enhancing fuel efficiency and crashworthiness in vehicles. Furthermore, manufacturers can shape steel billets into intricate designs, allowing them to create aesthetically pleasing and aerodynamic vehicle structures. In conclusion, the strength, durability, and versatility of steel billets make them essential in the transportation sector. They are used in various applications, ranging from vehicle components to infrastructure projects. By ensuring safety, reliability, and longevity, steel billets play a vital role in the industry.

- Q: How are steel billets used in the manufacturing of construction scaffolding?

- Steel billets are an essential raw material used in the manufacturing of construction scaffolding. These billets are initially heated and then passed through a series of rolling mills to achieve the desired shape and size for scaffolding components. Once the steel billets are rolled into the required shape, they are further processed to create various scaffolding parts, such as tubes, couplers, frames, and planks. These parts are then assembled to form the scaffolding structure that provides a safe and sturdy platform for workers to perform tasks at elevated heights during construction projects. The use of steel billets in the manufacturing of construction scaffolding offers several advantages. Firstly, steel is known for its exceptional strength and durability, making it an ideal material for scaffolding. Additionally, steel is resistant to corrosion and can withstand harsh weather conditions, ensuring the scaffolding remains reliable and safe throughout the construction process. Moreover, steel scaffolding is highly versatile and can be easily customized to fit different project requirements. The use of steel billets allows manufacturers to create scaffolding components of various sizes, shapes, and configurations to accommodate different construction needs. In conclusion, steel billets play a crucial role in the manufacturing of construction scaffolding. By utilizing these raw materials, scaffolding manufacturers can produce durable, reliable, and customizable scaffolding structures that enhance safety and efficiency on construction sites.

- Q: What are the different methods of surface cleaning for steel billets?

- Some of the different methods of surface cleaning for steel billets include abrasive blasting, acid pickling, mechanical cleaning, and electrochemical cleaning.

Send your message to us

Prime square alloy steel billet 120mm Q235

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords