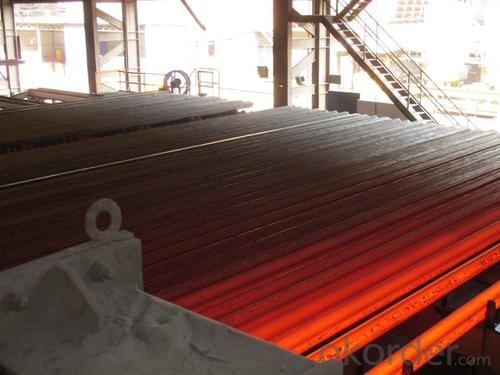

Prime square alloy steel billet 105mm Q235

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime square alloy steel billet 105mm Q235

Description of Prime square alloy steel billet 105mm Q235

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.

Main Feature of Prime square alloy steel billet 105mm Q235

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime square alloy steel billet 105mm Q235

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.

Specifications of Prime square alloy steel billet 105mm Q235

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime square alloy steel billet 105mm Q235

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

we always fix steel produce in container well to make it safe arrive at destination port

we always provide best and professional forward service for our buyer

we always apply 14days free detention for our buyers container in destination

we provide one set After-sales service for our buyer

we provide China inland steel market price report

we help our buyer become number one in local market .

- Q: How are steel billets preheated before processing?

- Steel billets can be preheated before processing using various methods depending on the specific requirements of the process and the type of equipment available. One common method is the use of natural gas or propane-fired furnaces. The billets are placed inside the furnace, and the temperature is gradually increased to the desired preheating temperature. Another method is the use of induction heating. This involves placing the billets inside a coil, and an alternating current is passed through the coil, which generates a magnetic field. This magnetic field induces electric currents within the billets, resulting in heat generation and preheating of the steel. Additionally, some preheating processes utilize electric resistance heating. In this method, the billets are placed between two electrodes, and an electric current is passed through the electrodes. The resistance to the flow of current generates heat, which preheats the steel billets. Preheating of steel billets is crucial as it helps to reduce the thermal shock experienced during subsequent processing steps. It also improves the overall efficiency of the process, as preheated billets require less energy to reach the desired processing temperature. Moreover, preheating helps to enhance the mechanical properties of the steel, making it easier to shape and manipulate during processing.

- Q: Billet heating furnace billet temperature reached, steel will be adhesion

- As soon as the melting point is reached, the part melts before sticking. But heating will swell a lot, you need to leave enough space.

- Q: What are the different types of steel billet shearing machines?

- There are several different types of steel billet shearing machines, including hydraulic shearing machines, mechanical shearing machines, and pneumatic shearing machines.

- Q: What are the different testing methods used for steel billets?

- To ensure the quality and suitability of steel billets for various applications, multiple testing methods are employed. These methods encompass: 1. Visual Inspection: The most straightforward and widely used technique involves visually examining the billets for visible defects like cracks, surface irregularities, or foreign materials. 2. Dimensional Inspection: To meet specific dimensional requirements, the length, width, and height of the billets are measured using calibrated tools, ensuring they adhere to the specified tolerances. 3. Ultrasonic Testing: Detecting internal defects, this non-destructive method employs high-frequency sound waves. By transmitting sound waves into the material and analyzing the reflected waves, flaws or inconsistencies can be identified. 4. Magnetic Particle Inspection: Utilized primarily to detect surface and near-surface defects, this method applies a magnetic field to the billet, followed by the application of a magnetic particle solution. Any cracks or defects cause the particles to accumulate, creating visible indications. 5. Eddy Current Testing: This technique involves passing an alternating current through a probe, generating an electromagnetic field. Placing the probe near the billet's surface allows the detection of defects through changes in electrical conductivity or magnetic permeability, which induce eddy currents. 6. Chemical Analysis: The composition of steel billets, including the percentage of elements like carbon, manganese, and silicon, is determined through chemical analysis. This ensures compliance with the required chemical composition for their intended use. 7. Tensile Testing: By subjecting a sample taken from the billet to tension until it fractures, tensile testing measures mechanical properties such as strength, ductility, and elasticity. The applied force and resulting elongation or deformation provide insights into the billet's mechanical characteristics. These testing methods comprehensively assess steel billets for defects, dimensional accuracy, and material properties. By ensuring adherence to industry standards and meeting specific application requirements, the suitability and quality of the billets are guaranteed.

- Q: How are steel billets used in the production of transmission components?

- In the production of transmission components, steel billets are indispensable raw materials. These semi-finished products are typically obtained through the casting process and have a rectangular or square shape with a larger cross-sectional area compared to the final product. To shape the steel billets into the desired forms, a series of processes such as forging, rolling, or extrusion are employed. Each of these processes aims to transform the steel billets into specific shapes and sizes required for transmission components like gears, shafts, bearings, and housings. Forging is a widely used method for shaping steel billets. It involves heating the billet and using mechanical force to deform it into the desired shape, thereby enhancing the strength and durability of the transmission components. Rolling, on the other hand, gradually reduces the cross-sectional area of the steel billets by passing them through a series of rollers. This process helps achieve the desired shape and dimensions of the components. In certain cases, extrusion is employed to produce complex shapes. This process involves forcing the steel billets through a die to obtain the desired form, allowing for the production of intricate transmission components like splined shafts or valves. After shaping the steel billets into the required forms, further machining processes such as cutting, drilling, and grinding are carried out to achieve the final specifications. These components are then heat-treated and coated to enhance their strength, durability, and resistance to corrosion. In summary, steel billets play a crucial role in the production of transmission components as they provide a versatile and reliable raw material that can be shaped into various forms. They ensure that the transmission components possess the necessary strength, durability, and precision required for efficient and reliable operation in vehicles and machinery.

- Q: How are steel billets coated or painted?

- Steel billets can be coated or painted through several methods. One common technique is hot-dip galvanizing, where the billets are immersed in a bath of molten zinc. This process forms a protective zinc coating on the surface of the steel, preventing corrosion. Another method is electroplating, which involves the deposition of a thin layer of metal, such as zinc or nickel, onto the billets using an electric current. Additionally, steel billets can be painted using various coating systems, such as powder coating or liquid paint, to provide a decorative finish or additional protection against rust and environmental factors.

- Q: How are steel billets used in the production of industrial pumps?

- Steel billets are used in the production of industrial pumps as they serve as the raw material for creating the pump's main components, such as the pump body and impeller. These billets are melted, cast, and then forged or machined into the desired shapes and sizes to form the pump's robust and durable structure.

- Q: How do steel billets contribute to the manufacturing of furniture and fixtures?

- Due to their unique properties, steel billets are indispensable in the production of furniture and fixtures. The strength and stability they offer are essential for constructing these items, providing a solid framework that can support their weight and load-bearing capacity. This ensures that the furniture and fixtures will remain functional for an extended period of time. Additionally, the malleability of steel billets allows for the creation of intricate designs and shapes, enhancing the aesthetic appeal of furniture and fixtures. Manufacturers can take advantage of this flexibility to produce a wide range of styles and patterns that cater to different consumer preferences and interior design themes. Moreover, steel billets can be easily welded, making them perfect for joining various components together during the manufacturing process. This welding capability ensures a seamless and secure construction, ultimately improving the overall quality and durability of the furniture and fixtures. Furthermore, steel billets possess corrosion-resistant properties, making them suitable for indoor and outdoor furniture and fixtures alike. This resistance to rust and decay guarantees that these items can withstand harsh environmental conditions, preserving their appearance and structural integrity over time. In conclusion, the role of steel billets in the manufacturing of furniture and fixtures cannot be overstated. Their strength, malleability, weldability, and corrosion resistance contribute to the durability, design flexibility, and longevity of these items, making them a preferred choice for both manufacturers and consumers.

- Q: What are the main factors affecting the impact toughness of steel billets?

- The impact toughness of steel billets can be affected by several main factors. Firstly, the toughness of the steel is significantly influenced by its chemical composition. Alloying elements like carbon, manganese, and nickel can enhance toughness. Higher carbon content increases hardness but decreases impact toughness. On the other hand, the addition of manganese and nickel promotes the formation of fine-grained structures, improving toughness. Secondly, the heat treatment process used during steel billet production plays a crucial role in their toughness. Annealing and quenching processes refine the microstructure of the steel, making it more resistant to cracking and brittle fracture. However, improper heat treatment or rapid cooling rates can lead to the formation of undesirable phases or microstructural defects, reducing impact toughness. Thirdly, the presence of impurities and inclusions in the steel also affects its toughness. Non-metallic inclusions, such as sulfides and oxides, act as stress concentrators and initiate crack propagation during impact loading. Therefore, steel with lower impurity levels and cleaner inclusion content exhibits higher toughness. Moreover, the grain size of the steel significantly influences its toughness. Finer grain sizes improve toughness due to the increased number of grain boundaries that act as barriers to crack propagation. Thus, steel billets with smaller grain sizes are more resistant to brittle fracture. Lastly, the mechanical working processes like hot rolling or forging can affect the toughness of steel billets. These processes induce deformation and strain hardening, increasing strength but potentially decreasing toughness. Careful control of deformation parameters is necessary to balance strength and toughness in steel billets. To summarize, the impact toughness of steel billets is influenced by various factors, including chemical composition, heat treatment, impurities and inclusions, grain size, and mechanical working processes. Understanding and optimizing these factors are crucial in producing steel billets with the desired toughness for specific applications.

- Q: Are steel billets prone to cracking during production?

- During the production of steel billets, there is a tendency for cracking to occur. This can happen for various reasons, such as improper cooling, excessive heating, or rapid cooling. The cooling process plays a crucial role in the production of steel billets as it impacts the microstructure and mechanical properties of the final product. If the cooling is not done correctly, it can create internal stresses within the billet, ultimately leading to cracking. Additionally, the presence of impurities or defects in the starting material can also contribute to the occurrence of cracks. Therefore, manufacturers must closely monitor and control the production process to minimize the risk of cracking and ensure the high quality of the steel billets.

Send your message to us

Prime square alloy steel billet 105mm Q235

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords