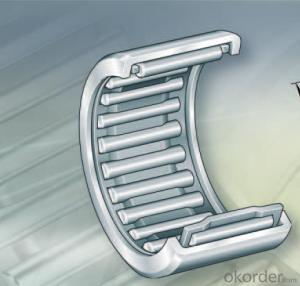

HK 1715 RS Needle Roller Bearing Drawn Cup Needle Roller Supply High Precision

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 900000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specifications:

Type: | Needle | Brand Name: | OEM | Bore Size: | 17 mm |

Outside Diameter: | 23 mm | Model Number: | HK 1715 RS | Precision Rating: | ABEC-1 |

Seals Type: | Open or Sealed | Number of Row: | Single Row | Place of Origin: | Jiangsu, China (Mainland) |

Material: | Chrome Steel | Lubrication: | Grease Lubrication | Package: | Plastic Bag and Box |

Equivalent: | HK 1715 RS |

Product Applications:

Needle roller bearings are mainly used in car engines, transmissions, compressors, cranes, etc.

Product Advantages:

1.Bearing Manufactory ( Have our own technical department)

2.High quality products (Long Life and low noise)

3.Well-daserved Reputation (Good Stock Guarantee)

4.Professional service ( Promptly shippment)

5.OEM Service,Sample is available

Packaging & Delivery

Packaging Details: | 1.industrial packing |

Delivery Detail: | in stock or 15-30days after P.O |

FAQ:

WHY CHOOSE US ???

1.More than 28 years export experience

2.Strict quality control

3.Delivery in time

4.OEM service are available with good price

5.Low MOQ

- Q: I need to buy bearings but I dont want to get the wrong one

- All okorder /

- Q: trying to figure out what type of bearing could be used in a pulley system with dynamic loads exceeding 1150 lb and 540 lb.

- Ball bearings manufacturers give detailed procedure on how to calculate and arrive to the proper selection. I advise to contact them and obtain their catalogues.

- Q: Can anyone explain me bearings?

- Here's a video explaining bearings. Did you have a specific question regarding bearings?

- Q: i noticed they had some dirt in them after rideing around a bit and it happens to be from just 2 bearings from 1 wheel, ive completely disasmbled the bearings and tried to put them back to getter but the ball bearings just keep locking up on me !!! its been frustrating me like crazy man, and i know its not from not having lube they always have lube in, its just the reassembly that wont go well.

- Joe, okorder

- Q: I need to know how to change my front wheel bearings on my 1996 honda passport 4 wheel drive

- The bearings are pressed into the uprights, so you need to take the front upright off the vehicle, press the old bearings (2) out and press two new ones in and reassemble.

- Q: I am a Roller derby girl and so I am NOT interested in the type of bearings that are for in-line skate! Please tell me how I can tell if the bearings are good for speed or not!

- I use Bones Swiss bearings and they have been very responsive and have made a big difference. If you want to know how fast a bearing is most have abec ratings, nine being the highest. However, as Bones Swiss are of better quality and faster than most bearings, they have omitted the abec rating. I highly reccommend the Bones Swiss bearings and if you want to get better than those, you get the ceramics. They are much more expensive though.

- Q: I'm in alot of downhill skating events but no wins. What bearings could i use that are the fastest in ur opinion and name them all i use are redz bonez.

- bones okorder /

- Q: I was wondering which bearings are faster, and which last longer with good care, independent 5's, or regular reds bearings. Thanks!

- Reds bearings are better I used to skate them and loved them but it is really worth spending the money for bones swiss or super reds.

- Q: how to replace front wheel bearings for 1997 mustang?

- Remove the front wheels, calipers and rotors. Then change the bearings..............easy!

- Q: I need to upgrade my wheels and probably bearings for my roller blades they are a 64mm wheel on right now and i know NOTHING about wheels and bearings, like do I have to stick with the same size wheel,can I use current bearings on there etc... I know I would like a nice smooth ride and preferably a gel type wheel... I am on a budget so I know going with a little lower grade bearing and a better wheel will optimize performance on a budget. I am in Canada so an international or Canadian seller is a must and I would like to have a name or model number so I know what to look up specifically if possible please and thank you!

- 64mm okorder /.. If you buy wheels and bearings, remember to transfer the spacers from your old wheels or buy aluminum ones. The wheels will not roll well without them.

Send your message to us

HK 1715 RS Needle Roller Bearing Drawn Cup Needle Roller Supply High Precision

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 900000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches