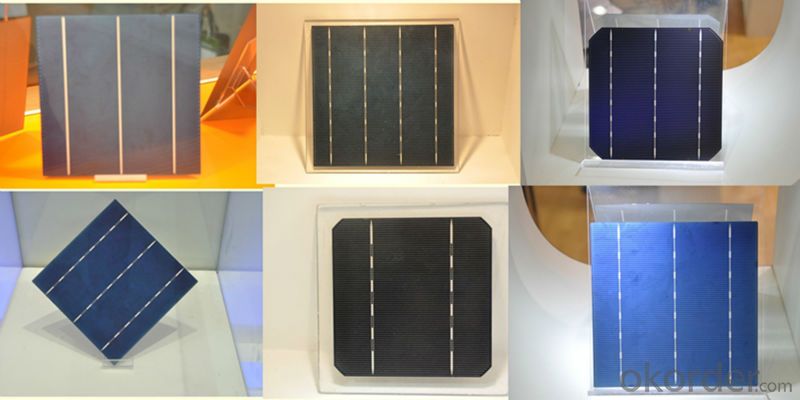

High Quality A Grade Monocrystalline Solar Grade Silicon Wafer Polycrystalline 5v 17.2% Solar Cell

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

hot sale solar cell

1.16.8%~18.25% high efficiency

2.100% checked quality

3.ISO9001/ISO14001/TUV/CE/UL

4.stable performance

We can offer you the best quality products and services, don't miss !

POLY6'(156*156)

Polycrystalline Silicon Solar cell

Physical Characteristics

Dimension: 156mm×156mm±0.5mm

Diagonal: 220mm±0.5mm

Thickness(Si): 200±20 μm

Front(-) Back(+)

Blue anti-reflecting coating (silicon nitride); Aluminum back surface field;

1.5mm wide bus bars; 2.0mm wide soldering pads;

Distance between bus bars: 51mm . Distance between bus bars :51mm .

Electrical Characteristics

Efficiency(%) | 18.00 | 17.80 | 17.60 | 17.40 | 17.20 | 16.80 | 16.60 | 16.40 | 16.20 | 16.00 | 15.80 | 15.60 |

Pmpp(W) | 4.33 | 4.29 | 4.24 | 4.19 | 4.14 | 4.09 | 4.04 | 3.99 | 3.94 | 3.90 | 3.86 | 3.82 |

Umpp(V) | 0.530 | 0.527 | 0.524 | 0.521 | 0.518 | 0.516 | 0.514 | 0.511 | 0.509 | 0.506 | 0.503 | 0.501 |

Impp(A) | 8.159 | 8.126 | 8.081 | 8.035 | 7.990 | 7.938 | 7.876 | 7.813 | 7.754 | 7.698 | 7.642 | 7.586 |

Uoc(V) | 0.633 | 0.631 | 0.628 | 0.625 | 0.623 | 0.620 | 0.618 | 0.617 | 0.615 | 0.613 | 0.611 | 0.609 |

Isc(A) | 8.709 | 8.677 | 8.629 | 8.578 | 8.531 | 8.478 | 8.419 | 8.356 | 8.289 | 8.220 | 8.151 | 8.083 |

MONO5'(125*125mm)165

Monocrystalline silicon solar cell

Physical Characteristics

Dimension: 125mm×125mm±0.5mm

Diagonal: 165mm±0.5mm

Thickness(Si): 200±20 μm

Front(-) Back(+)

Blue anti-reflecting coating(silicon nitride); Aluminum back surface field;

1.6mmwide bus bars; 2.5mm wide soldering pads;

Distance between bus bars: 61mm . Distance between bus bars :61mm .

Electrical Characteristics

Efficiency(%) | 19.40 | 19.20 | 19.00 | 18.80 | 18.60 | 18.40 | 18.20 | 18.00 | 17.80 | 17.60 | 17.40 | 17.20 |

Pmpp(W) | 2.97 | 2.94 | 2.91 | 2.88 | 2.85 | 2.82 | 2.79 | 2.76 | 2.73 | 2.70 | 2.67 | 2.62 |

Umpp(V) | 0.537 | 0.535 | 0.533 | 0.531 | 0.527 | 0.524 | 0.521 | 0.518 | 0.516 | 0.515 | 0.513 | 0.509 |

Impp(A) | 5.531 | 5.495 | 5.460 | 5.424 | 5.408 | 5.382 | 5.355 | 5.328 | 5.291 | 5.243 | 5.195 | 4.147 |

Uoc(V) | 0.637 | 0.637 | 0.636 | 0.635 | 0.633 | 0.630 | 0.629 | 0.629 | 0.628 | 0.626 | 0.626 | 0.625 |

Isc(A) | 5.888 | 5.876 | 5.862 | 5.848 | 5.839 | 5.826 | 5.809 | 5.791 | 5.779 | 5.756 | 5.293 | 5.144 |

FAQ:

Q:How can i get some sample?

A:Yes , if you want order ,sample is not a problem.

Q:How about your solar panel efficency?

A: Our product efficency around 17.25%~18.25%.

Q:What’s the certificate you have got?

A: we have overall product certificate of ISO9001/ISO14001/CE/TUV/UL

- Q: How does the thickness of an anti-reflective coating affect the efficiency of a solar silicon wafer?

- The thickness of an anti-reflective coating on a solar silicon wafer affects its efficiency by reducing the amount of light reflection at the surface. A thicker coating can minimize reflection more effectively, allowing more light to be absorbed by the wafer and increasing the overall efficiency of the solar cell.

- Q: Can solar silicon wafers be used in solar-powered desalination plants?

- Yes, solar silicon wafers can be used in solar-powered desalination plants. These wafers are commonly used in solar panels to convert sunlight into electricity, which can then be utilized in desalination processes. By harnessing solar energy, these plants can effectively power the desalination process, making it an environmentally friendly and sustainable solution for producing fresh water from seawater.

- Q: What are the disadvantages of using solar silicon wafers?

- One major disadvantage of using solar silicon wafers is their high production cost. The process of manufacturing silicon wafers involves advanced technology and requires expensive materials, making the overall production expensive. Additionally, the extraction and purification of silicon from raw materials contribute to environmental concerns and energy consumption. Another drawback is their limited efficiency in converting sunlight into electricity, as silicon wafers have a lower absorption rate for certain wavelengths of light. This can lead to lower overall energy generation compared to other types of solar cells. Moreover, silicon wafers are rigid and bulky, making them less suitable for integration into flexible or lightweight devices.

- Q: How does the size of a solar silicon wafer affect the efficiency of a solar panel?

- The size of a solar silicon wafer does not directly affect the efficiency of a solar panel. The efficiency is primarily determined by the quality of the silicon material and the manufacturing processes used. However, larger wafers can lead to larger solar cells, which can increase the overall power output of a panel.

- Q: Are there any safety concerns associated with handling solar silicon wafers?

- Yes, there are safety concerns associated with handling solar silicon wafers. Silicon wafers are fragile and can easily break, leading to potential lacerations or puncture injuries. Additionally, the wafers are often coated with various chemicals, such as photoresist or anti-reflective coatings, which may be hazardous if inhaled or ingested. It is essential to follow proper handling procedures, wear appropriate personal protective equipment, and work in a controlled environment to minimize any potential risks.

- Q: How does the efficiency of a solar silicon wafer change with air pollution?

- The efficiency of a solar silicon wafer decreases with increased air pollution. Air pollutants such as dust, smog, and particulate matter can accumulate on the surface of the wafer, reducing its ability to absorb sunlight and convert it into electricity. Additionally, pollutants can cause shading, reducing the amount of sunlight reaching the wafer. Therefore, maintaining clean air is essential to maximize the efficiency of solar silicon wafers.

- Q: What is the role of a solar silicon wafer in a solar cell?

- The role of a solar silicon wafer in a solar cell is to serve as the substrate or base material where the photovoltaic process takes place. The silicon wafer is typically doped with impurities to create a p-n junction, which allows for the conversion of sunlight into electricity. It acts as the main absorber of light, generating electron-hole pairs when photons hit its surface. These electron-hole pairs are then separated and directed by the electric field within the solar cell, ultimately producing an electric current.

- Q: What is the effect of fill factor on the efficiency of a solar silicon wafer?

- The fill factor is an important parameter that affects the efficiency of a solar silicon wafer. It represents the ability of the solar cell to convert sunlight into electrical power. A higher fill factor indicates better utilization of the available solar energy and leads to higher efficiency. It is directly related to the internal resistance and the voltage and current characteristics of the solar cell. Therefore, optimizing the fill factor is crucial for maximizing the efficiency of a solar silicon wafer.

- Q: What is the role of solar silicon wafers in building-integrated photovoltaics?

- Solar silicon wafers play a crucial role in building-integrated photovoltaics (BIPV) as they are the key component used to convert sunlight into electricity. These wafers are made of high-purity silicon and are responsible for capturing and absorbing solar energy. They are then wired together to form solar cells, which are integrated into the building's architecture, such as rooftops or facades. The solar silicon wafers essentially act as the building blocks of BIPV systems, enabling the generation of clean and renewable energy directly from sunlight.

- Q: Can solar silicon wafers be used in solar-powered air conditioning systems?

- Yes, solar silicon wafers can be used in solar-powered air conditioning systems. Silicon wafers are commonly used in solar panels to convert sunlight into electricity, which can then be used to power various appliances, including air conditioning systems.

Send your message to us

High Quality A Grade Monocrystalline Solar Grade Silicon Wafer Polycrystalline 5v 17.2% Solar Cell

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords