6 inch Multi Solar Silicon Wafer -- 156 x 156 mm by Solar Silicon Wafer Manufacturers

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

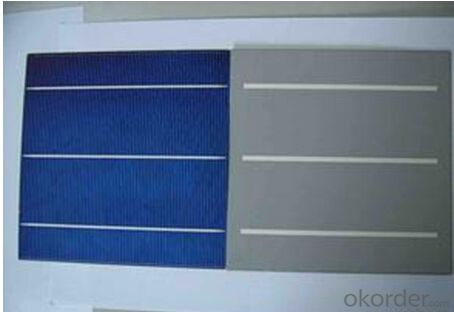

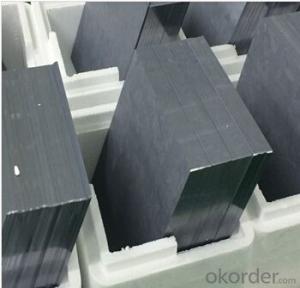

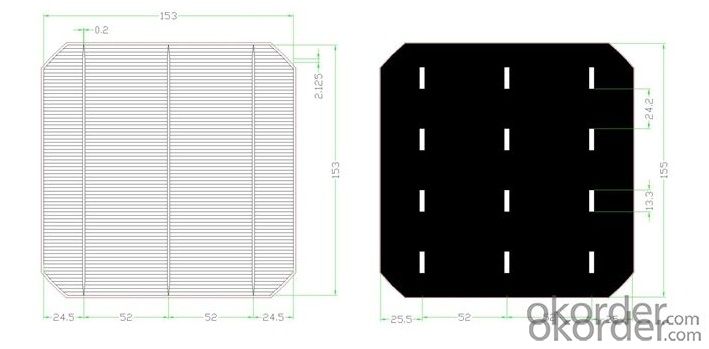

6 Inch Multi Solar Cell -- 156 x 156 mm

FEATURES

`Long Service Life

`High Efficiency Solar Cells

`Special Aluminum Frame Design

`High Transmission, Low Iron Tempered Glass

`Advanced Cell Encapsulation

Solar Module Specifications

Mono 80W—100W

Module | Type (36 Series) | |||||

Encapsulation | Glass/EVA/Cells/EVA/TPT | |||||

Parameters | SNM-M80(36) | SNM-M85(36) | SNM-M90(36) | SNM-M95(36) | SNM-M100(36) | |

Max power | Pm(W) | 80W | 85W | 90W | 95W | 100W |

Tolerance | +/-3% | |||||

Open circuit voltage | Voc(V) | 21.2 | 21.8 | 21.8 | 22.3 | 22.6 |

Short circuit current | Isc(A) | 4.84 | 5.00 | 5.30 | 5.44 | 5.68 |

Max. power voltage | Vmp(V) | 17.5 | 18.0 | 18.0 | 18.5 | 18.5 |

Max. power current | Imp(A) | 4.57 | 4.72 | 5.00 | 5.14 | 5.40 |

Dimensions | (L*W*H) | 1200x540x35mm | ||||

Net Weight | (kg) | 9 | ||||

Max. system voltage | (V) | 1000VDC | ||||

Operate Temp. Scope | -40/+85'C | |||||

Resistance | 227g steel ball fall down from 1m height and 120m/s wind | |||||

Warranty | Pm is no less 90% in 10 years and no less 80% in 25 years | |||||

STC | (Standard Test Condition: 1000W/m2, AM1.5, and 25'C) | |||||

Picture show

- Q: What are the challenges in manufacturing large-sized silicon wafers?

- One of the main challenges in manufacturing large-sized silicon wafers is ensuring uniformity and maintaining high quality throughout the entire wafer. As the size of the wafer increases, it becomes more difficult to control factors such as temperature, impurities, and crystal structure. This can lead to variations in thickness, crystal defects, and other imperfections that can impact the performance of electronic devices built on these wafers. Additionally, handling and processing large wafers require specialized equipment and techniques to mitigate the risk of breakage and damage.

- Q: What are the advantages of using a solar silicon wafer?

- There are several advantages of using a solar silicon wafer. Firstly, silicon is abundantly available in the Earth's crust, making it a cost-effective and sustainable material for solar panels. Secondly, silicon has excellent electrical properties, allowing for efficient conversion of sunlight into electricity. Additionally, silicon wafers have high durability and can withstand harsh environmental conditions, ensuring a long lifespan for solar panels. Lastly, silicon wafers can be easily fabricated into various shapes and sizes, providing flexibility in design and installation options for solar systems.

- Q: What is the typical weight of a solar silicon wafer?

- The typical weight of a solar silicon wafer is around 5 to 10 grams.

- Q: How are solar silicon wafers affected by temperature gradients?

- Solar silicon wafers are indeed affected by temperature gradients. When exposed to temperature variations, the thermal expansion and contraction of the silicon wafer can cause mechanical stress, leading to cracks or even breakage. Additionally, temperature gradients can also impact the efficiency of the solar cells, as higher temperatures tend to decrease their performance. Therefore, it is crucial to carefully manage and control temperature gradients to ensure the longevity and optimal functioning of solar silicon wafers.

- Q: How do solar silicon wafers perform in earthquake-prone environments?

- Solar silicon wafers are designed to withstand various environmental conditions, including earthquake-prone environments. These wafers are made from durable materials and undergo rigorous testing to ensure their resilience. They are equipped with strong frames and mounting systems that can absorb vibrations and movements caused by earthquakes. Additionally, advanced installation techniques such as anchoring and bracing are employed to enhance their stability. Overall, solar silicon wafers are designed to perform reliably and safely even in areas prone to seismic activity.

- Q: Are there any alternatives to using solar silicon wafers in solar cells?

- Yes, there are alternatives to using solar silicon wafers in solar cells. Some of these alternatives include thin-film solar cells made from materials such as cadmium telluride (CdTe), copper indium gallium selenide (CIGS), and organic photovoltaics (OPV). These alternative materials offer advantages such as flexibility, lightweight, and potentially lower manufacturing costs. However, their efficiency and stability still need further development to compete with traditional silicon wafers.

- Q: Can solar silicon wafers be used in solar-powered air conditioners?

- Yes, solar silicon wafers can be used in solar-powered air conditioners. These wafers are commonly used in solar panels to convert sunlight into electricity. In solar-powered air conditioners, the electricity generated by the silicon wafers can be used to power the cooling mechanism, providing an energy-efficient and sustainable alternative to traditional air conditioners.

- Q: Are all solar panels made with silicon wafers?

- No, not all solar panels are made with silicon wafers. While silicon is the most commonly used material for solar panels, there are also other types of solar panels that use different materials such as thin-film solar panels made from materials like cadmium telluride or copper indium gallium selenide (CIGS).

- Q: How is the back surface field created in a solar silicon wafer?

- The back surface field in a solar silicon wafer is created by diffusing a dopant, usually boron, onto the rear surface of the wafer. This process forms a p-n junction, which generates an electric field that helps to separate the photogenerated electrons and holes, thereby enhancing the efficiency and performance of the solar cell.

- Q: What is the expected degradation rate of a solar silicon wafer over time?

- The expected degradation rate of a solar silicon wafer over time can vary depending on various factors such as the quality of the wafer, the manufacturing process, and the environmental conditions it is exposed to. However, on average, a well-maintained silicon wafer can experience a degradation rate of around 0.5% to 1% per year.

Send your message to us

6 inch Multi Solar Silicon Wafer -- 156 x 156 mm by Solar Silicon Wafer Manufacturers

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords