High-performace pipeline ball valve DN 2 inch

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of pipeline ball valve

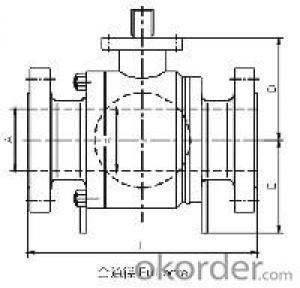

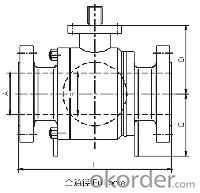

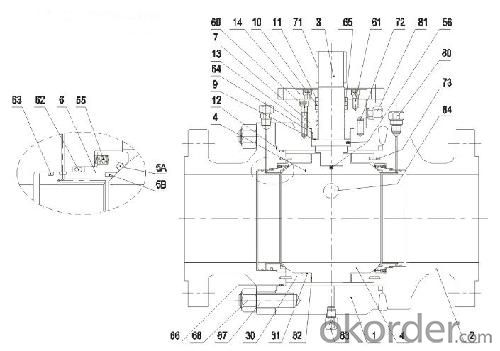

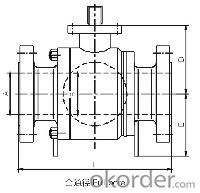

Body of high-performance pipeline ball valve is forged structure.The connection type for body and vice-body can be BB(bolted connection)and WB(welded connection).The WB(welded connection)and the LWB(Fully-welded extended stem)structure isadopted for buried ball valves,as shown below.

High performance pipeline ball valve series has the feature of strength,high perfect sealing,maintenance-free,long life and so on.The production of this series ball valve adopts the international advanced ball valve design and manufacturing technology,selects high-quality materials in accordance with the standard selection of materials and combines with advanced materials forming forging technology.At the same time,with the years of ball valve design and manufacturing experience,the use of advanced processing and manufacturing equipment and production and processing technology,through the first-class inspection and testing equipment and instruments,perfect quality assurance management system and excellence in the production of high-performance philosophy can ensure the quality of valves.This series of valve has the performance of a high strength,defect-free forging body,excellent sealing performance,even at maximum pressure difference(full pressure),it will still be able to ensure that seal without leakage,after frequent switching action to realize a safe usage in the transportation of oil,natural gas,coal gas,and other special medium transportation pipeline.

Performance & Dimensions of pipeline ball valve

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 1.6 Mpa 2 Mpa 5 Mpa 8 Mpa 10 Mpa 16 Mpa 25 Mpa 42 Mpa |

150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize | |

Valve Size | 50 mm 80 mm 100 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 550 mm 600 mm 650 mm 700 mm 750 mm 800 mm 850 mm 900 mm 1000 mm 1050 mm 1200 mm 1400 mm |

2 inch 3 inch 4 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 22 inch 24 inch 26 inch 28 inch 30 inch 32 inch 34 inch 36 inch 40 inch 42 inch 48 inch 56 inch customize | |

Actuator | Electric Handle Hydraulic Pilot-hydraulic Pneumatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

Medium | Gas customize |

Medium Temperature | -29~150℃ -46~150℃ customize |

Application Fields | Electricity Petrochemical Power Station customize |

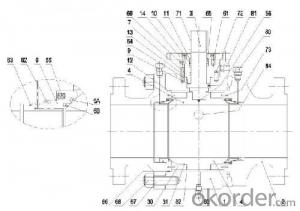

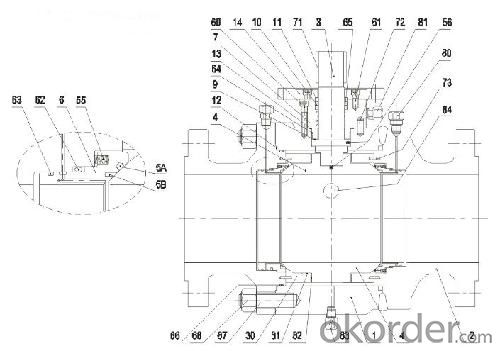

Component Materials of pipeline ball valve

1-Body Material | A105 A350-LF2-M customize |

2-Bonnet | A105 A350-LF2-M customize |

3-Stem | 4410+ENP customize |

4-Ball | A350 LF2+ENP A105+ENP customize |

5-Material of Valve Seat | fluorine rubber customize |

5-Seat | Nylon PTFE peek DEVLON customize |

6-Seat ring | A105 ENP+A322 4140 customize |

7-Packing chamber | A322 4140+ENP A105 customize |

9-Stem gasket | RPTFE customize |

10-Packing | graphite PTFE customize |

11-Packing gland | ENP+A350 LF2 ENP+A105 customize |

12-Body gasket | Stainless steel+graphite customize |

13-Gasket | Stainless steel+graphite customize |

14-Top flange | A105 A350 LF2 customize |

30-Supporting board | A105 A350 LF2 customize |

31-Gasket | customize |

55-Seat spring | B637 Inconel X750 customize |

56-Anti-static spring | B637 Inconel X750 customize |

60-Bolt | A320 L7 A193-B7 A193-B7M customize |

61-Bolt | A193-B7 A193-B7M A320 L7 customize |

62-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

63-Fire-safe ring | flexible graphite customize |

64-O-ring | hydrogenated nitrile butadiene rubber fluorine rubber customize |

65-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

66-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

67-Bolt | A193-B7M A320 L7 A193-B7 customize |

68-Nut | A194 2HM A194 4 A194 2H customize |

71-Key | A322 4140 customize |

72-Locating pin | A322 4140 customize |

73-Locating pin | A322 4140 customize |

80-Seat injection valve | WCB+ENP customize |

81-Stem injection valve | WCB+ENP customize |

82-Bearing | PTFE+Stainless steel customize |

83-Drainage valve | Stainless steel customize |

84-Vent valve | Stainless steel customize |

85-Actuator | customize |

90-Plate | Stainless steel customize |

Standards Applied of pipeline ball valve

Design Standard | API 6D customize |

Connection Standard | ASME B 16.25-2007 ASME B 16.5 ASME B 31.4 ASME B 31.8 DIN GB、GB/T JB、JB/T JIS customize |

Test Standard | API 6D customize |

Face to Face | API 6D customize |

Pressure-temperature rating | ASME B 16.34-2004 customize |

Marking | MSS SP-25 customize |

Images of pipeline ball valve:

FAQ of pipeline ball valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: Model 28 BS 12.5 HP engine intake valve sticks. Please advise.When under a full load like tall grass, it runs great, but when the load is not as heavy, the intake valve sticks open, spewing gas back through the carb and mis-firing.

- Don't know anything about configuration of this model by number, but I can recommend you hit up your library for a copy of How to Repair Briggs Stratton Engines, by Paul Dempsey. I have 2nd edition, but I think they are currently on fourth edition. First thing I would do is pull the head and inspect the valve seats. Lap the valves if necessary. If the valve seats are good to go, then you have to look at the lifting mechanism. Does it have rocker arm, or straight push lifters? Could the cam shaft have been damaged (i.e., have you hit any stumps with it)?

- Q: I recently had an echo and they said their was a slight tricuspid valve leak but it was 19 and anything less than 20 is considered normal. I have no clue what that means. Does any one have and clue on what scale she was talking about. Also she stated that the machine are so sensitive these days that the majority of people are found to have some sort of leak. Is this the case??????

- The tricuspid valve is a valve in your heart that, like any other valve, makes the blood flow in only one direction. When your heart pumps blood into your body, this valve is normally closed so the heart only pumps it in your arteries, and not back in your veins whence it came. When this valve doesn't close shut completely, a little quantity of blood leaks through the little opening there. You can see this with an echocardiography which you said you had done. Yes, the value of 19 is really low, and the fact that the limit to normality is 20, so you're close to it, doesn't mean that you're almost sick. Keep in mind that these limits that doctors have are some guidelines, and they all have a safe zone. Plus, this is not the kind of lesion that evolves, it doesn't mean that as the years go by the little space in your valve will get bigger and bigger - nothing of that sort. It is probably a thing that you had since forever, and you will have it the same your whole life with no problems at all. In the end, let me say that if you are brave enough to go to a doctor (many people aren't, and that really sucks), you should be brave enough to ask him/her what they mean when they say certain stuff, without worrying that your question might be stupid or already answered. You didn't go to med school, and it is the doctor's duty to explain to you what is happening in your body just as it is to diagnose and treat you. Best of luck!

- Q: I was considering making a ball valve PVC air rifle or something of the sort using a PVC air canister and a hand pump, but I wanted to know about it, last year I made one that was air tight but air leaked out of the top of the pump which really annoyed me, I looked further onto the it and found out that there was a Bike Tyre valve, What does it do? Does it let air flow in but stop it from coming out? and where would I find some good designs as well as the items needed to make it? And don't bother answering 'Buy an air soft gun' because Australia does not retail those.

- hi there in canada , at any big truck tire repair place they have tire valves that are like bunker fittings, that is to say a valve that has a threaded bottom end with nuts and rubber washers, you would drill the appropriate size hole in the pipe and put the valve through and tighten the nuts up against the washers making an air tight seal, that should work for you if they have them in au, good luck

- Q: i have a leak on the front of that valve cover and the oil is going down to the headers,,how can i fix the problem.?how do i install da gasket do i need any special things??thanx for tha help

- He could have placed helicoils in to repair that. without the splendid torque the pinnacle will warp and this could actual reason the oil leak.in fact ask him why he did no longer restoration it whilst it became aside. The regulation probable calls so you might furnish him of undertaking to repair it as quickly as.you may no longer could pay for that and you may ask to work out the gaskets he would be removing to interchange returned. If he takes it aside and reuses the gaskets he purely put in there will be issues down the line.

- Q: I did a compression test, and I have a broken valve. everything else is in perfect condition besides this valve and I have carbon getting built up in one of my pistons. Can I run the car like this? What cause this from happening what was the cause age?1999 Ford Explorer 4.0 OHV with 146k,miles

- you cant drive w/ a broken valve lying around in the engine. but yes you can drive w/ carbon build up, it causes the engine to run a lil warmer and prolly acts as a oil seal to the piston even after the rings go out.and youve ran a lot of gas thru in 12 yrs so carbon build up is normal,valves dont always break tho unless you were giving it hell an it jus seen so much wear an got thin an finally broke.mayb its not jammed into the head and its jus broke

- Q: will a blow off valve work with out an intercooler???(civic 2000)and also, is a blow off valve a turbo?whats the diffrence between a turbo and a blow off valve?? thankss..

- A blow off or pop off valve controls the boost or pressure the turbo or supercharger is pushing into the engine.A turbo makes the boost.The blow off valve controls it so you wont run too much boost or pressure into your engine and leave pieces of it all over the street.The blow off valve can be adjusted to control the boost,6- 8 lbs.should be sufficient for a street application.The blow off valve simply allows the excess pressure built up in the turbo to be vented or blown off so it wont be forced into the engine.The boost on a supercharged or blower application is controlled by swapping the blower pulley to either underdrive the blower or overdrive the blower,depending on which way you want to go.

- Q: this question is related to Ball valves, In actuated valve for the selection of actuator we need differential pressure across the valve so I wanted to know that what is meant by differential pressure?

- This Site Might Help You. RE: what is the definition of differential pressure for valves? this question is related to Ball valves, In actuated valve for the selection of actuator we need differential pressure across the valve so I wanted to know that what is meant by differential pressure?

- Q: I have a shut off valve under the sink that leaks when you try to turn it OFF. Why is that?I need to fix faucet leak as well. do i need to shut water off to fix faucet? Need to fix valve first. Cant figure out why valve leaks when turning off.

- Because the stem washer is worn out and needs replacing, you will have to shut off the water to the whole house and you might as well replace the shutoff, probably just about as cheap and a lot more reliable fix.

- Q: adjusting the overhead valves on briggs and stranton 14.5 engine

- Roll the engine over until the valve is completely closed. You can do this by watching the valve close, then turn the engine over until it just strats to raise. Now turn it back half way. Now losen the rocker arm and place a .003mm to .005mm filler gage between the push rod and the rocker. Tighten the rocker arm nut down so that the filler gage pulls out with a light drag. Do this with the other rocker and you are good to go.

- Q: ive had my yz250f for more than a year and i havent had the valves adjusted......it still starts up in under 5 kicks and rides great.......are there any signs that indicate you need your valves adjusted besides not being able to start it?

- With titanium valves you do not wait until they start ticking. It is a race bike not a Ford Pinto. Do I need to define the term preventative maintenance? They need to be checked a minimum of once a year, if not more. Don't wait for problems, take it in now. As to super cleats answer, I'm sure the factory riders would love to know your secret for making a 4 stroke race bike start on the first kick every time, because they sure haven't figured that one out yet.

Send your message to us

High-performace pipeline ball valve DN 2 inch

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords