High-performace pipeline ball valve 2500 Class

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of pipeline ball valve

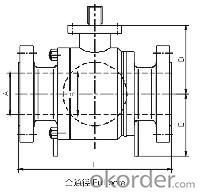

Body of high-performance pipeline ball valve is forged structure.The connection type for body and vice-body can be BB(bolted connection)and WB(welded connection).The WB(welded connection)and the LWB(Fully-welded extended stem)structure isadopted for buried ball valves,as shown below.

High performance pipeline ball valve series has the feature of strength,high perfect sealing,maintenance-free,long life and so on.The production of this series ball valve adopts the international advanced ball valve design and manufacturing technology,selects high-quality materials in accordance with the standard selection of materials and combines with advanced materials forming forging technology.At the same time,with the years of ball valve design and manufacturing experience,the use of advanced processing and manufacturing equipment and production and processing technology,through the first-class inspection and testing equipment and instruments,perfect quality assurance management system and excellence in the production of high-performance philosophy can ensure the quality of valves.This series of valve has the performance of a high strength,defect-free forging body,excellent sealing performance,even at maximum pressure difference(full pressure),it will still be able to ensure that seal without leakage,after frequent switching action to realize a safe usage in the transportation of oil,natural gas,coal gas,and other special medium transportation pipeline.

Performance & Dimensions of pipeline ball valve

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 1.6 Mpa 2 Mpa 5 Mpa 8 Mpa 10 Mpa 16 Mpa 25 Mpa 42 Mpa |

150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize | |

Valve Size | 50 mm 80 mm 100 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 550 mm 600 mm 650 mm 700 mm 750 mm 800 mm 850 mm 900 mm 1000 mm 1050 mm 1200 mm 1400 mm |

2 inch 3 inch 4 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 22 inch 24 inch 26 inch 28 inch 30 inch 32 inch 34 inch 36 inch 40 inch 42 inch 48 inch 56 inch customize | |

Actuator | Electric Handle Hydraulic Pilot-hydraulic Pneumatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

Medium | Gas customize |

Medium Temperature | -29~150℃ -46~150℃ customize |

Application Fields | Electricity Petrochemical Power Station customize |

Component Materials of pipeline ball valve

1-Body Material | A105 A350-LF2-M customize |

2-Bonnet | A105 A350-LF2-M customize |

3-Stem | 4410+ENP customize |

4-Ball | A350 LF2+ENP A105+ENP customize |

5-Material of Valve Seat | fluorine rubber customize |

5-Seat | Nylon PTFE peek DEVLON customize |

6-Seat ring | A105 ENP+A322 4140 customize |

7-Packing chamber | A322 4140+ENP A105 customize |

9-Stem gasket | RPTFE customize |

10-Packing | graphite PTFE customize |

11-Packing gland | ENP+A350 LF2 ENP+A105 customize |

12-Body gasket | Stainless steel+graphite customize |

13-Gasket | Stainless steel+graphite customize |

14-Top flange | A105 A350 LF2 customize |

30-Supporting board | A105 A350 LF2 customize |

31-Gasket | customize |

55-Seat spring | B637 Inconel X750 customize |

56-Anti-static spring | B637 Inconel X750 customize |

60-Bolt | A320 L7 A193-B7 A193-B7M customize |

61-Bolt | A193-B7 A193-B7M A320 L7 customize |

62-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

63-Fire-safe ring | flexible graphite customize |

64-O-ring | hydrogenated nitrile butadiene rubber fluorine rubber customize |

65-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

66-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

67-Bolt | A193-B7M A320 L7 A193-B7 customize |

68-Nut | A194 2HM A194 4 A194 2H customize |

71-Key | A322 4140 customize |

72-Locating pin | A322 4140 customize |

73-Locating pin | A322 4140 customize |

80-Seat injection valve | WCB+ENP customize |

81-Stem injection valve | WCB+ENP customize |

82-Bearing | PTFE+Stainless steel customize |

83-Drainage valve | Stainless steel customize |

84-Vent valve | Stainless steel customize |

85-Actuator | customize |

90-Plate | Stainless steel customize |

Standards Applied of pipeline ball valve

Design Standard | API 6D customize |

Connection Standard | ASME B 16.25-2007 ASME B 16.5 ASME B 31.4 ASME B 31.8 DIN GB、GB/T JB、JB/T JIS customize |

Test Standard | API 6D customize |

Face to Face | API 6D customize |

Pressure-temperature rating | ASME B 16.34-2004 customize |

Marking | MSS SP-25 customize |

Images of pipeline ball valve:

FAQ of pipeline ball valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: I was told Wed. that I need to have my aortic valve replaced. I was wondering if anyone could share their experience with this surgery good or bad. I am meeting with the surgeon on the 26th, and am very nervous. Any tips and or suggestions appreciated. I'm a 39 year old female.Thanks in advance

- if you have a tissue valve you will not need to be on coumadin the blood thinner but will need to have surgery repeated later on in life. if you have a mechanical valve placed then you will need to be on coumadin and typically it takes about a week to get your blood theraputic, then you will need to probably need to have you blood drawn weekly a few times immediately after. then it tapers down to once a month checks generally. goofd luck to you.

- Q: Need some info. Ok, four valves per cylinder is better than two valves per cylinder. Fine, why did Ford REVERT to only 3 valves (my guess is to save cost SOHC)? Audi and VW are using five valves per cylinder on some cars, does this offer any advantage over a four valve engine? Maserati even experimented with a six valve per cylinder!!!! (see link) http://www.maserati-alfieri .uk/alfieri26.htm but abandoned it (my guess is cost again?) Why are we stuck at four valves or would more valves actually render more horsepower? Pop some ideas best answer to reasonable answer...

- One advantage is that of pressure differentials. For the intake of a non-aspirated engine, not supercharger, the pressure differential between the atmosphere and the cylinder is about 14.6 lbs. maximum, atmospheric pressure. For the exhaust there is a high pressure in the cylinder and therefore it is easier to clear out most of the burned fuel mixture. So exhausting the cylinder is easier than getting the fuel-air mixture into the cylinder. It is a bit simpler to make one large exhaust valve and two smaller intake valves as far as the layout of the valves in the cylinder head. You save on parts is one consideration. Also, high revving engines make more horsepower but passenger cars never see the advantage of higher horsepower like racing engines do. If you build racing engines, it is not that difficult to use the same cylinder heads or last years heads. If you don't build racing engines, you are not worried about high horsepower designs and more about keeping the cost of the engine reasonable. You probably never use all the horsepower your engine is capable of delivering so why pay for more engine than you will ever use?

- Q: hey...im kinda confusedis cochlear an artificial valve???and if not..what is an artificial valve??

- Hello, i found this information online, hope it will be helpfull... ?Artificial valves can be used to replace damaged valves in the body that are no longer functioning to keep blood flowing in one direction only. ?Most artificial valves have a fabric ring surrounding them, which allows a surgeon to sew the device into place during implantation. ?Where appropriate, artificial valves are constructed from collagen-rich materials, such as pericardial tissues which have been obtained from pigs or cows and treated (to denature any animal proteins), to minimise the risk of rejection by the human body. Other materials used are cobalt-chromium alloys, low-temperature carbon and titanium alloy with pyrolytic carbon discs or balls.

- Q: I have an 98 Mitsubishi Eclipse rs and its a little jerky while driving and i think it might be the PCV valve but I don't know where it is located.. where is it? and would this cause the check engine light to come on?

- Your okorder okorder , which covers all Eclipse/Talon models.

- Q: I recently had an echo and they said their was a slight tricuspid valve leak but it was 19 and anything less than 20 is considered normal. I have no clue what that means. Does any one have and clue on what scale she was talking about. Also she stated that the machine are so sensitive these days that the majority of people are found to have some sort of leak. Is this the case??????

- finding on the severity of the valve situation it fairly is severe. If it have been severe you certainly could have indications that could assist you recognize previous to now. Ask the physician how severe the valve insufficiency is. A mitral valve prolapse could make you sense mild headed. The tricuspid valve insufficiency could convey approximately severe issues. There are various circumstances that would reason this. it fairly is great to your heart professional to describe your situation. In any experience it fairly is no longer something to fool around with or placed off. while you're actually not chuffed with the solutions do no longer hesitate to get a 2d opinion.

- Q: adjusting the overhead valves on briggs and stranton 14.5 engine

- Roll the engine over until the valve is completely closed. You can do this by watching the valve close, then turn the engine over until it just strats to raise. Now turn it back half way. Now losen the rocker arm and place a .003mm to .005mm filler gage between the push rod and the rocker. Tighten the rocker arm nut down so that the filler gage pulls out with a light drag. Do this with the other rocker and you are good to go.

- Q: What is a foot and check valve what's the difference between the two?

- A foot valve is a check valve with a screen to stop debris. It depends on whether you're pumping water with alot of sediment.

- Q: what is the purpose of valves such as: gate valve, foot valve and globe valve in the industry?

- the valves control the flow

- Q: I have a rainbird Sprinkler system. One of the zones the sprinklers do not pop up. Someone said maybe the valve is stuck closed from the winter. How do you open and close the valve manually to loosen it back up. and where would this valve be located in the little green junction box near where the zone starts????

- they dont really stick from the winter. i would say if the valve has a problem the diaphram needs replacing on the inside of it. ( all you have to do is find the same kind of valve and take the old parts out of the valve and replace them, the top, and the solenoid with the new valve's parts. they can be anywhere in your yard. ive even found the valve boxes buried under bushes. some installers don't put them in boxes, they just bury the valves. if you know where any of the green boxes are open the lids and see what's inside. sometimes more than one valve will be in a box. turn the solenoid on the valve. ( this will be the peice that the wire are connected to on the valve. dont turn the solenoid too much or it will come out. just a 1/4 to 1/2 a turn or so maybe a little more or less. and when you find the valve that turns on the zone 8 that is not working that is the valve for that section. you may even be able to hear the valve trying to come on when the timer shows it is running. if not, then check for power at the valve. if no power. there is a short, bad connection, or bad module in the timer. if power- replace just the solenoid first. if that doesnt work rebuild the valve. if you have no luck finding the box with zone 8 in it then try a few tips. get a screwdriver and poke around where some other valve boxes are. they may be close together. use a wire locator or hire a professional to locate the valve and show you how to repair it. to manually open and close the valve- open upthe solenoid like i said. or use the bleeder if the valve has one.

- Q: so i'm replacing a one hole faucet, and i'm stuck at the very first step. the cold water valve turned off with no problems. i tried to turn on the cold water and none came out. unfortunately, the hot water valve just squeaks and goes around and around, never cutting off the water. when i turn it, it also leaks a minute amount of water, though regardless of which way i twist, it stops as soon as i do. i can't just unplug the hot water valve with it still running water, so does anyone have any ideas? how does one replace a valve like this to begin with? is it possible that there is a shut off valve for the house that i myself can access (without having to call someone to shut off my water)? in case you haven't noticed, i am a bit plumbing deficient, so if you could explain it without too much jargon, it would be much appreciated.

- You do not need to empty the water heater. Just shut off a valve at the heater and that will shut off all the hot water in your home. Do not empty water heater. I would also recommend a new shut off valve for the future.

Send your message to us

High-performace pipeline ball valve 2500 Class

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords