High-performace pipeline ball valve PN 600 Class

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of pipeline ball valve

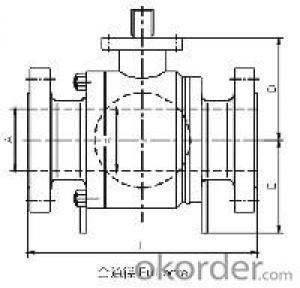

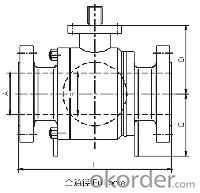

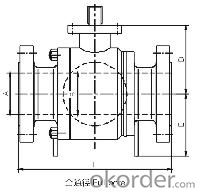

Body of high-performance pipeline ball valve is forged structure.The connection type for body and vice-body can be BB(bolted connection)and WB(welded connection).The WB(welded connection)and the LWB(Fully-welded extended stem)structure isadopted for buried ball valves,as shown below.

High performance pipeline ball valve series has the feature of strength,high perfect sealing,maintenance-free,long life and so on.The production of this series ball valve adopts the international advanced ball valve design and manufacturing technology,selects high-quality materials in accordance with the standard selection of materials and combines with advanced materials forming forging technology.At the same time,with the years of ball valve design and manufacturing experience,the use of advanced processing and manufacturing equipment and production and processing technology,through the first-class inspection and testing equipment and instruments,perfect quality assurance management system and excellence in the production of high-performance philosophy can ensure the quality of valves.This series of valve has the performance of a high strength,defect-free forging body,excellent sealing performance,even at maximum pressure difference(full pressure),it will still be able to ensure that seal without leakage,after frequent switching action to realize a safe usage in the transportation of oil,natural gas,coal gas,and other special medium transportation pipeline.

Performance & Dimensions of pipeline ball valve

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 1.6 Mpa 2 Mpa 5 Mpa 8 Mpa 10 Mpa 16 Mpa 25 Mpa 42 Mpa |

150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize | |

Valve Size | 50 mm 80 mm 100 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 550 mm 600 mm 650 mm 700 mm 750 mm 800 mm 850 mm 900 mm 1000 mm 1050 mm 1200 mm 1400 mm |

2 inch 3 inch 4 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 22 inch 24 inch 26 inch 28 inch 30 inch 32 inch 34 inch 36 inch 40 inch 42 inch 48 inch 56 inch customize | |

Actuator | Electric Handle Hydraulic Pilot-hydraulic Pneumatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

Medium | Gas customize |

Medium Temperature | -29~150℃ -46~150℃ customize |

Application Fields | Electricity Petrochemical Power Station customize |

Component Materials of pipeline ball valve

1-Body Material | A105 A350-LF2-M customize |

2-Bonnet | A105 A350-LF2-M customize |

3-Stem | 4410+ENP customize |

4-Ball | A350 LF2+ENP A105+ENP customize |

5-Material of Valve Seat | fluorine rubber customize |

5-Seat | Nylon PTFE peek DEVLON customize |

6-Seat ring | A105 ENP+A322 4140 customize |

7-Packing chamber | A322 4140+ENP A105 customize |

9-Stem gasket | RPTFE customize |

10-Packing | graphite PTFE customize |

11-Packing gland | ENP+A350 LF2 ENP+A105 customize |

12-Body gasket | Stainless steel+graphite customize |

13-Gasket | Stainless steel+graphite customize |

14-Top flange | A105 A350 LF2 customize |

30-Supporting board | A105 A350 LF2 customize |

31-Gasket | customize |

55-Seat spring | B637 Inconel X750 customize |

56-Anti-static spring | B637 Inconel X750 customize |

60-Bolt | A320 L7 A193-B7 A193-B7M customize |

61-Bolt | A193-B7 A193-B7M A320 L7 customize |

62-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

63-Fire-safe ring | flexible graphite customize |

64-O-ring | hydrogenated nitrile butadiene rubber fluorine rubber customize |

65-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

66-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

67-Bolt | A193-B7M A320 L7 A193-B7 customize |

68-Nut | A194 2HM A194 4 A194 2H customize |

71-Key | A322 4140 customize |

72-Locating pin | A322 4140 customize |

73-Locating pin | A322 4140 customize |

80-Seat injection valve | WCB+ENP customize |

81-Stem injection valve | WCB+ENP customize |

82-Bearing | PTFE+Stainless steel customize |

83-Drainage valve | Stainless steel customize |

84-Vent valve | Stainless steel customize |

85-Actuator | customize |

90-Plate | Stainless steel customize |

Standards Applied of pipeline ball valve

Design Standard | API 6D customize |

Connection Standard | ASME B 16.25-2007 ASME B 16.5 ASME B 31.4 ASME B 31.8 DIN GB、GB/T JB、JB/T JIS customize |

Test Standard | API 6D customize |

Face to Face | API 6D customize |

Pressure-temperature rating | ASME B 16.34-2004 customize |

Marking | MSS SP-25 customize |

Images of pipeline ball valve:

FAQ of pipeline ball valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: I am 16, and i have a leaky heart valve. What makes it worse so i can try to prevent from it getting worse? please help.

- Not much can make it better or worse as long as you are in good health and are taking care of yourself. One thing that is very important when you have valve issues is to stay hydrated.

- Q: Bought a 1986 GMC 350day 1 started up good - idle was rough - idle really too low, when brakes where applied, it would backfire. (day 2) Changed oil which was really dark - oil filter too... ghanged spark plugs and wires. % 10 improvement... Engine lack power and vibrates but no more backfire.day 4 Changed Cap and rotor - % 30 improvement - day 5 Got the manifold gasket replaced. Same condition but silent... day 6 Changed coil in cap ... Changed fuel filter % 60 improvement... The thing ran like new... Full power I started beliving again..Got full oil pressure 300 kpa - no valve noise Ran 30 minutes on highway.... Valves started making noise especially on driver's side... Engine lost lots of power, and vibrates a lot... doesnt heat up to much but oil pressure seems very low. (day 7) Start up the thing, and even when cold and choke on, oil pressure not as good as in the beginning. What went wrong

- loosing oil pressure like that,it sounds like the oil pump.if the parts arent getting oil,it will loose power.also check the timing,it could be off and loosing power.if the timing is off,it will make the valves noisy.

- Q: Last year an echo revealed severe aortic valve regurgitation with low ef of 37 but ecg was normal. i am 36 yrs old. I have noticed that i often have chest pain when i lie on my left (especially after a heavy drinking or if my bp is high) but the pain subsides when i lie on my right or back. Is it possible that my aortic valve only leaks when i lie on my left side, if so, can I continue living a normal life without needing valve replacement surgery if avoid lieing on my left side. or i'm i fooling myself, is the heart damage progressing silently?

- Hello, You don't tell us *why* your doctors think, you developed this problem with your aortic valve in the first place? Has there been any infection of the valve with germs, (bacterial endocarditis)? Did you have Rheumatic Fever as a child? Were you born, with stenosis or regurgitation of your aortic valve? Do you have abnormally early, clogging-up of your artery-linings with cholesterol?

- Q: Is there a devise to reverse the flow to a cylinder. Not the pump. But a inline flow deverter that would shift the flow from one side of the cylinder to the other at the end of the stroke automatically without a person interjecting.ie it extends fully then the flow reverses retracting it fully. Then the flow reverses, and it extends fully and so on.Preferably, with as little lag as possible during the transition.I want the pump to run constantly(not reversing) and the cylinder to run constantly. Do not worry about the heat generated.Would love something that ran off the main cylinder(like a secondary piston or valve that would opendivert flow at the end of the stroke) through linkage. But, I am open to electronics if need be. Further more want the return to be metered so that the push and pull forces will be the same(metered through a smaller opening to adjust for the rod).Thankyou

- That I know of, there is nothing you can buy to do this...it would have to be built into the cylinder. A steam train main piston and valving does exactly as you describe, but through a linkage. You could hook up a MAC manual cylinder reversing valve (below) to a bar attached to the piston rod with adjustable stops to shift the valve at each end of the stroke. No electricity or electronics required, just air. Check with Parker for same valve for hydrualics.

- Q: I have a 3-circuit sprinkler system in my yard (built by me, last year). I discovered this week that I overtightened the connection between the valves and the downstream pipes, and 2 of the three valves are cracked, and leaking, at the connection. I replaced all 3 valves, and now I need to reconnect them to the supply. But this means I'm working backward - when I bult the system last year, I worked downstream - I built the manifold first, connected the valves, then the remainder of each branch. Now, I have to make the new manifold fit the valves, and naturally, they don't line up perfectly. Any tips/tricks on connecting valves in this situation? Is there such a thing as flexible pipe that can withstand continuous pressure? I'm using unions at both ends of each valve to help things go together/come apart more easily.

- valve manifolds are something that requires practice and experience. i used to struggle with them at work until i did a good bit of them. 3 zones is not that many valves so it shouldnt be too difficult. if they wont line up exactly right, i would recommend adding longer peices of pipe to the mainline side of the vavles and re routing the supply line futher back and you will have more room to flex the pipe and vavles into the Tees and 90s. do not use any form of flexible pipe on any mainline. you will regret it. lol the bigger the hole you dig will give you the most room and the more pipe, and room will give you more flexability to build the manifold. it is easier to connect the valves the way you did it first though, but you can do it either way. good luck and hope this helps

- Q: I was diagnosed with Mitral Valve prolapse...I'm 21, 5.5 tall and 130lbs, I had a healthy lifestyle...my doctor said that my case isn't really sever..but i'm taking medications to keep it this way...something i cannot ask my doctor about, would intercourse be harmful to me? and how should I deal with it??? is it okay for me to have children in the future? and could my MVP be cured without surgery??

- good blood does not mix with bad blood. The values have nothing to do with that as the two sides of the heart are separate. With Mitral valve incompetence or prolapse, the valve does not close like it is suppose to. That allows back flow of blood. If bad enough, the treatment is a valve replacement. With Mitral valve stenosis, the valve does not open like it is suppose to. That prevents flow through the valve. The treatment is a valve replacement or sometimes a simple cut in the valve to relieve the stenosis can be done. Either way, if bad enough, surgery is needed, not pills.

- Q: I went to turn the water off with the shut-off valve so that I could do some work on the toilet tank (replacing old and leaky fill valve) but the water won't shut off. I'm assuming that I'll need to replace the shut-off valve itself but could anything else be causing the problem? The funny thing is, the leaky fill valve that I wanted to replace has now stopped hissing and leaking and the tank seemingly fills fine. But of course the water can't be turned off completely.Just wanted to check make sure that there aren't anything else I should do or consider before I went off to replace the shut-off valve.Thanks

- If you are turning on that valve and it doesn't shut off the flow of water to the toilet, then the valve should be replaced. Now, if it's not leaking, you don't HAVE to replace the valve. But of course, if the toilet overflowed you wouldn't have any easy way of shutting off the water There are many, many choices in replacing valves. You have to determine which kind of valve you have - sweat on, male or female thread, or compression - size of pipe coming out of the wall - size of thread for the fill tube. Once you have that figured out, you do need to turn off the house water before you take the old valve off. One more choice: Spend the extra couple of bucks and get a 1/4 turn ball type valve.

- Q: My eight month old daughter was just diagnosed with pulmonary valve stenosis. Anyone have an experience with this? Did you have cardiac catherization? Did that fix the problem?

- I don't know if it's the same but my son had aortic stenosis when he was born. After many tests it just went away and no they did not have to do a catherization. Never caused him any problems either.

- Q: I have this air canister i want to attach to a homemade Airsoft gun. (please no comments or answers on that).The air canister has an opening on both ends. I thought for simplicity, put a filler valve on one end and a connection to the gun on the other.Exactly what kind of one way filer valve will i need, most of the ones i look at look like propane tank connections and those are for filling and dispensing into the system.

- schrader okorder

- Q: how to get adjust the valves on a craftsman mower with a briggs and stratton with ohv 18hp? Iv'e heard you adjust them around 5 thousands with a feeler gauge. But im confused about what position to adjust them. Iv'e heard you wait till one of the valves is closed while the other is open and adjust that one. Then repeat till you got them adjusted. Whats the proper way?

- I have never worked on the lawn mower engine. I have adjusted valves on motorcycles which have overhead valves. There are markings on the ignition generator that designate which valve would be in the correct position. However, if you spin the crank which will move the valves up and down, you can adjust each valve when you can shake the valve tappet. This happens when the valve is closed and the cam comes away from the tappet. You should be able to feel play in the tappet when the valve is closed. Adjust this closed valve. Be careful not to make your clearance to tight. This is worse than loose. Looseness makes noise and excessive wear over time but tight will burn your valve seat and ruin the valve. I have to wonder if you really need to do anything to valves on a ten year old tractor. It's only a tractor, not anything high revving or high performance. My tractor has overhead valves and was new in the early 90's. Never did anything to it but change the oil. If you do plan on doing it, good luck.

Send your message to us

High-performace pipeline ball valve PN 600 Class

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords