High-performace pipeline ball valve DN3 inch

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of pipeline ball valve

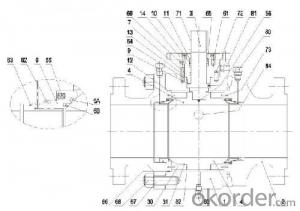

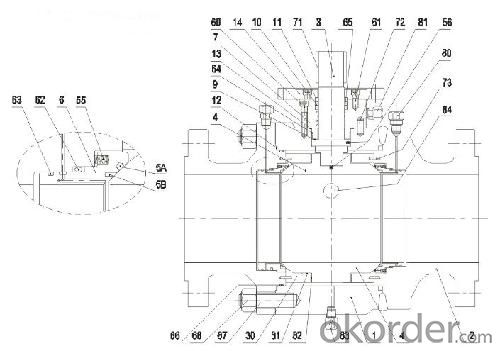

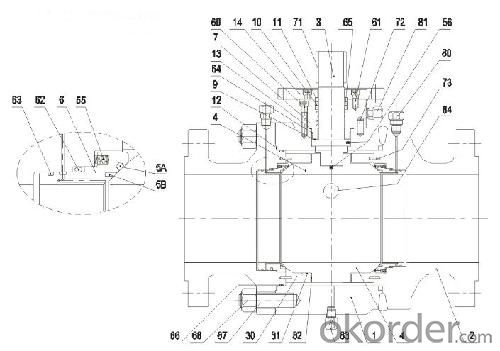

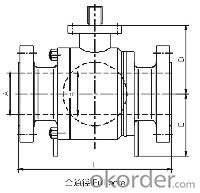

Body of high-performance pipeline ball valve is forged structure.The connection type for body and vice-body can be BB(bolted connection)and WB(welded connection).The WB(welded connection)and the LWB(Fully-welded extended stem)structure isadopted for buried ball valves,as shown below.

High performance pipeline ball valve series has the feature of strength,high perfect sealing,maintenance-free,long life and so on.The production of this series ball valve adopts the international advanced ball valve design and manufacturing technology,selects high-quality materials in accordance with the standard selection of materials and combines with advanced materials forming forging technology.At the same time,with the years of ball valve design and manufacturing experience,the use of advanced processing and manufacturing equipment and production and processing technology,through the first-class inspection and testing equipment and instruments,perfect quality assurance management system and excellence in the production of high-performance philosophy can ensure the quality of valves.This series of valve has the performance of a high strength,defect-free forging body,excellent sealing performance,even at maximum pressure difference(full pressure),it will still be able to ensure that seal without leakage,after frequent switching action to realize a safe usage in the transportation of oil,natural gas,coal gas,and other special medium transportation pipeline.

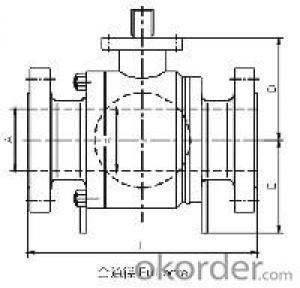

Performance & Dimensions of pipeline ball valve

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 1.6 Mpa 2 Mpa 5 Mpa 8 Mpa 10 Mpa 16 Mpa 25 Mpa 42 Mpa |

150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize | |

Valve Size | 50 mm 80 mm 100 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 550 mm 600 mm 650 mm 700 mm 750 mm 800 mm 850 mm 900 mm 1000 mm 1050 mm 1200 mm 1400 mm |

2 inch 3 inch 4 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 22 inch 24 inch 26 inch 28 inch 30 inch 32 inch 34 inch 36 inch 40 inch 42 inch 48 inch 56 inch customize | |

Actuator | Electric Handle Hydraulic Pilot-hydraulic Pneumatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

Medium | Gas customize |

Medium Temperature | -29~150℃ -46~150℃ customize |

Application Fields | Electricity Petrochemical Power Station customize |

Component Materials of pipeline ball valve

1-Body Material | A105 A350-LF2-M customize |

2-Bonnet | A105 A350-LF2-M customize |

3-Stem | 4410+ENP customize |

4-Ball | A350 LF2+ENP A105+ENP customize |

5-Material of Valve Seat | fluorine rubber customize |

5-Seat | Nylon PTFE peek DEVLON customize |

6-Seat ring | A105 ENP+A322 4140 customize |

7-Packing chamber | A322 4140+ENP A105 customize |

9-Stem gasket | RPTFE customize |

10-Packing | graphite PTFE customize |

11-Packing gland | ENP+A350 LF2 ENP+A105 customize |

12-Body gasket | Stainless steel+graphite customize |

13-Gasket | Stainless steel+graphite customize |

14-Top flange | A105 A350 LF2 customize |

30-Supporting board | A105 A350 LF2 customize |

31-Gasket | customize |

55-Seat spring | B637 Inconel X750 customize |

56-Anti-static spring | B637 Inconel X750 customize |

60-Bolt | A320 L7 A193-B7 A193-B7M customize |

61-Bolt | A193-B7 A193-B7M A320 L7 customize |

62-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

63-Fire-safe ring | flexible graphite customize |

64-O-ring | hydrogenated nitrile butadiene rubber fluorine rubber customize |

65-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

66-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

67-Bolt | A193-B7M A320 L7 A193-B7 customize |

68-Nut | A194 2HM A194 4 A194 2H customize |

71-Key | A322 4140 customize |

72-Locating pin | A322 4140 customize |

73-Locating pin | A322 4140 customize |

80-Seat injection valve | WCB+ENP customize |

81-Stem injection valve | WCB+ENP customize |

82-Bearing | PTFE+Stainless steel customize |

83-Drainage valve | Stainless steel customize |

84-Vent valve | Stainless steel customize |

85-Actuator | customize |

90-Plate | Stainless steel customize |

Standards Applied of pipeline ball valve

Design Standard | API 6D customize |

Connection Standard | ASME B 16.25-2007 ASME B 16.5 ASME B 31.4 ASME B 31.8 DIN GB、GB/T JB、JB/T JIS customize |

Test Standard | API 6D customize |

Face to Face | API 6D customize |

Pressure-temperature rating | ASME B 16.34-2004 customize |

Marking | MSS SP-25 customize |

Images of pipeline ball valve:

FAQ of pipeline ball valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: hi i have mitral valve prolapse/dysautonomia. when i get chest pains, its when i try to breathe. like i can take a little breath but if i take more my chest hurts. used to be pretty scary. i understand dysautonomia, but know know why it hurts to breathe in my heart sometimes. please help!

- Mitral valve prolapse is known to lead to chest pain, but the exact cause for the chest pain is not understood. The chest pain related to mitral valve prolapse is described as atypical, because it does not have the typical characteristics of other heart related pain. It is possible that your chest pain may or may not be related to your mitral valve prolapse. Chest pain that occurs or worsens with breathing is suggestive of a problem with the lining around the lungs (pleurisy.) A musculoskeletal cause like a pulled muscle is also possible. Anxiety would also be a possible cause. None of these conditions are serious. Chest pain resulting from MVP is not known to lead to any negative health consequences. Discuss it with your Cardiologist if you remain concerned.

- Q: IT USUALLY TAKES 2 SECONDS TO START THE MOTOR. NOW, IT TAKES OVER 40 SECONDS AT 7 AM. IT ALMOST KILL THE BATTERY. IF YOU PARK FOR 1 HOUR, 2ND START TAKES 10 SECONDS. IS THIS HAPPENING BECAUSE THE VALVES NEEDS ADJUSTING? HOW AND WHAT IS THE EASY WAY OF VALVES TUNE-UP?

- Good call, it most likely is the valve clearance. As the valves wear, they get tighter until they actually stay open a bit (when cold). As the engine warms up, the aluminum head pushes the cam away from the valve stems a bit, and some clearance comes back. Check 'em, adjust 'em, and you should be good to go. For most chinese 150's, you'll need to remove the plastic around the engine, then pull off the valve cover - you'll see the rocker arms inside, with locking nuts and adjustment screws. Set the crank at TDC on the compression stroke (about 1/2 turn after the intake valve closes) and then adjust the clearance - get specs from your manual, or just make sure that there's at least 0.1 mm gap if you don't have the specs.

- Q: After shutting off the hot and cold water lines to my washer to remove the unit from my laundry room i noticed a small leak coming from the hot water valve as if the valve is not completely closing. The valves themselves should be roughly 10 years old and were extremely tight when attempting to close them, my question is how big of a job is this to replace the water valve? Is it as simple as turning off the main water to the house and replacing the valve or are these typically soldered on? Currently i just ran the hose for the hot water to the drain line to prevent water from leaking onto the floor so is this something that is a fairly non issue once i hook the lines back up to the washer and turn them back on? Or is this something i should get addressed asap?

- Laundry Water Valve

- Q: My question mainly pertains to Electric Motor-driven Motor Operated Valve Actuators.

- This Site Might Help You. RE: How does an electric motor operated valve (MOV) actuator work? My question mainly pertains to Electric Motor-driven Motor Operated Valve Actuators.

- Q: Hello all,I have a1990,BMW 525i.I bought this car from another guy about year back and drive around 13000 kms.1.Do i need to adjust the valves(both inlet and outlet).2What is the importance of valve adjustment3Does it affect the mileage4.As a regular maintenance for how many kms can i drive without valve adjustmentExpecting your valuable replies.

- If your engine is silent,u dont disturb the valve clearances. if your maintaing the car with dealers or qualified mechanics,they will tell you if valve adjustments are required. so dont worry much.

- Q: okay, so i have a 2003 cr125 that i wanted to trade for a 4 stroke bike, and i found someone with a 2006 kx250f that wants to trade. He said all the bike needs to be running are 4 valves. The bike is in very good condition from the pictures i saw. How much are the 4 valves going to cost if i bring it to a mechanic shop? is the trade worth it? or should i just keep looking? thanks!p.s.- my cr is in absolute mint condition, and i never even rode it because it is just to much bike for me and i am not use to 2 strokes

- Kx250f Valves

- Q: Is there a devise to reverse the flow to a cylinder. Not the pump. But a inline flow deverter that would shift the flow from one side of the cylinder to the other at the end of the stroke automatically without a person interjecting.ie it extends fully then the flow reverses retracting it fully. Then the flow reverses, and it extends fully and so on.Preferably, with as little lag as possible during the transition.I want the pump to run constantly(not reversing) and the cylinder to run constantly. Do not worry about the heat generated.Would love something that ran off the main cylinder(like a secondary piston or valve that would opendivert flow at the end of the stroke) through linkage. But, I am open to electronics if need be. Further more want the return to be metered so that the push and pull forces will be the same(metered through a smaller opening to adjust for the rod).Thankyou

- even though this patent claims it will save money by eliminating a servo controller, it would seem to me to be an expensive item in and of itself. Other mechanisms would use linkages and lost motion to control a pilot shuttle valve. This would operate like the valve assemble for steam reciprocating pumps.

- Q: hi friends i want to know about the calibration technque of foundation fieldbus based control valve by a analog source

- * okorder moreinfo

- Q: like they say on 4 strokes you gotta go get valve jobs, and they cost bout 300 they say? well what does the mechanic do? can it be done at home and your just adjusting them?

- i'm 18 and race a crf40r i admire the motorbike. in case you desire to flow extra decrease priced i might decide for 2 stroke. have faith it or not 2 stroke is extra maintence even though it is lots extra decrease priced to rebuild. A 2 stroke on long tracks with enormous sweapers is purely as speedy as a 450 if not speedier. I enjoyed my 250 haha. 450's are somewhat a combat on the song they supply a real undesirable arm pump by using engine breaking. and 250 4 strokes are like driving the previous one hundred twenty five's all you do is shift. in case you may desire to get an rm 250 2 stroke they have the extra appropriate potential bands and have very solid bottomw end.

- Q: I have a Chevy Silverado 2500 5.7L V8. I have been having problems with passing smog. First one failed because it needed a new cat. Replaced it and tested again. NOx emissions are off the chart (1450/1006 max of 992/59615/25mph). I replaced the EGR valve based on a suggestion. Quick test today said the NOx emissions are still way off. Suggested that I change the EGR solenoid valve and also pull the EGR valve and use a coat hanger to clean some of the carbon build up. I purchased a new solenoid today but looking at it I noticed something. Since there are what are appear to be two ports on one side of the solenoid, I must have replaced the vacuum hose onto the wrong one after replacing the EGR valve. How much would this make a difference on the test readings taken? Would it be beneficial to just replace the solenoid anyway or try to test again with the current one but connected properly?

- Need to know the YEAR of your 2500 Silverado! ADDED: Thanks for the additional information, Yes that will cause an issue if the vacuum solenoid is connected wrong, but is very important to pay attention to what EGR valve is being installed (as this vehicle came with 2 different types of EGR valves (the negitive backpressure and the positive backpressure type) Here is how to test it: 1. Check the Exhaust Gas Recirculation (EGR) valve solenoid to have only 2 wires. If it does, the EGR valve is a negative back pressure style valve identified by an N stamped after the number on the valve. 2. With this type of valve, the solenoid is an on/off type and the scan tool control is 0/100%. To check the valve, pump the valve up/open by using a hand vacuum pump with the engine off. Start the engine and the valve should slam closed, and the vacuum on the hand pump should go to 0 inches. The engine should start normal. The EGR valve should not pull open with the engine idling when vacuum is reapplied. An internal bleed will dump off any vacuum applied until a certain amount of exhaust backpressure is applied to the valve. 3. If the valve moves, replace it using an Original Equipment (OE) part using the number on the valve that is calibrated per application. 4. If there are no problems found with the valve, install a vacuum gauge in-line with the solenoid and EGR valve and test drive to monitor the amount of vacuum applied. 5. The valve should have vacuum applied when in gear and off idle. Vehicle speed is needed on some models (manual transmission). ADDED: I don't know if you understand but, If your valve has N (negative) stamped on top and you have a 2 wire EGR vacuum solenoid than everything is correct!

Send your message to us

High-performace pipeline ball valve DN3 inch

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords