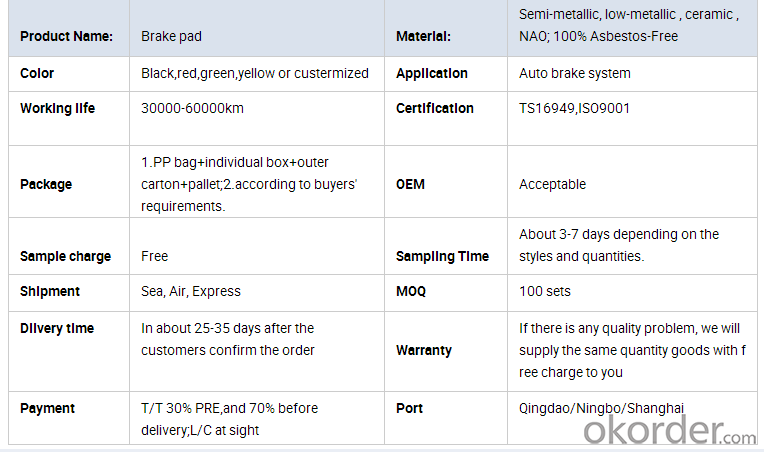

Good quality auto brake system brake pads manufacturer in china

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 300000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications

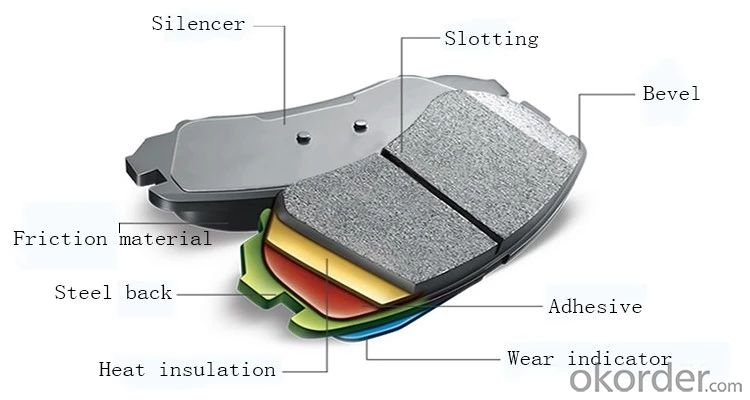

1.High quality brake pad featuring with stable friction coefficient,none noise,none-asbestos,none-dust,long using life,reasonable wearing rate.

2.Surface finished: paint, powder coat; electronic paint

3.No noise,long life .

4 Reasonable price,good quality ,prompt delivery

5.Be able to pass the E-mark authentication.

6. Complete models for different vehicles(passenger cars,lgiht truck,heavy truck,bus)

7.Professional Perfomance Auto parts supplier ,Manufacture according to customer's requirment.

9.Strong material of stable fiction coefficient under a wide range of temperatures

10. Original: CHINA

Our Service

1. Delivery for Sample: 3-15 Days.

2. Delivery time: 10-30 Working Days/ Depend on Order Quantity.

3. Shipment: by Sea, by Air or Express.

4. Sales Service: Any information from you will be responded within 24 hours.

We provide professional After-Sales Service for you!

Tracking your goods after shipping until you received them satisfyingly!When you got the

goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer

the solve way for you.

- Q: I have a 2005 Dodge Ram 1500 quad cab pickup. I went camping over the weekend and while driving home the ABS/Brake warning light came on. I knew that my brake fluid was a little low so I stopped filled it and continued to drive. The warning lights continued to stay on and I noticed that the actual tail lights stayed on the whole time.( My brake lights didn‘t work). Even with the car off. I had to disconnect the battery. Any Ideas what could be causing this?

- This was tremendously helpful as serving to to diagnose the concern! Our 2007 Camry began to have problems after a brake job within the back. It has been intermittently going wacky. Sometimes it labored most occasions now not. It was advocated by means of the vendor to interchange the $5000 ABS brake actuator process. I began with exchanging the ABS/tempurture manage pc that is under the passenger dash and it had no result. I made up our minds to get some electrical contact cleaner thinking that perhaps the connector was once soiled causing the partial connection. However, once I was once down looking at the connections and sensors I discovered the left driver aspect connector was once no longer thoroughly seated. It gave the look to be set but when you pulled, the connector would come off. Sincerely the rubber throughout the connector got squished to the again of the connector, causing the connector to no longer entirely click into position. Correcting the connector in order that it clicked into position entirely solved the drawback! Simple as that however hard to search out. I inspiration it perhaps an easier situation to begin diagnosing. Hope it helps. Thanks once more, Caleb Kelsay

- Q: Hey so I got this old 1986 Kawasaki ninja a few weeks ago for a $1000. Probably overpaid for it but it was in really good condition for being so old and the last owner fixed up a bunch of stuff.Mechanically is seems really good and i have been riding is for almost 200 miles already. One bad thing is that the gas mileage doesn‘t seem to be very good. Probably because its old. Going to try one of those fuel additives.Anyways. The main reason im here is because there is a soft scraping/ grinding noise when i push the bike. Meaning the bike is off and in neutral. I was thinking the noise is coming from the brakes grinding on the rotors. The pads seem to be good, but the rotors need to be resurfaced because there are some noticeable ridges in them. I still have not pin pointed the noise because I have to keep both hands on the bike to move it around. Any other ideas where the noise is coming from? Also should i be concerned about this?

- A little bit of scuffing is normal, no rotor is perfectly flat. Best way to check is to put the bike on the center-side or a bike-bench and rotate the wheels while inspecting the rotation. The drive-chain can also make some noise, check for tension and lube.

- Q: My mechanic said he wasn't sure what it is, though he knew it would be expensive (dealer only part). Its leaking and needs to be replaced. Its opposite the master cylinder, and attached to the firewall. How do I know whether his estimate is accurate (when I finally get one) being that its a dealer only part? I got front and rear brakes done by these same guys back in February, shouldn't they have caught it then?

- You are increasing the temp. of 200g of Cu 130 degrees celsius. I think you need to find the specific heat of Cu which will tell you a number of calories needed to raise the temp of 1 g. of Cu 1 degree C. Multiply the specific heat by 26,000 (200g x 130 degrees) to get number of calories.

- Q: What is the role of the car brake system? Mainly composed of several parts.

- Brake cylinder, brake pedal, brake cylinder, brake cylinder, vacuum booster, brake pipe, brake clamp, brake pads, should be on the

- Q: Hi,I‘ve got a trailer with simple tow bar braking system.I would like to change by an electric brake system because it is smoother.Is it expensive to do the change and complicated ?Is anyone have done that before ?Thanks.

- If a boat trailer don't do it. If a hauling trailer $50+ per wheel. As U need a complete drum and brake system plus a Controller inside the truck.

- Q: I need a new brake cable for my mountain bike, but every cable that I find at regular sporting goods stores are too low of a gauge for downhill brake stress that I put on the cable. The cable setup on my bike is very tight and there is little play between brake 0% and 100%. Its the cable for the rear tire. That‘s the only way that works for me.So, can anyone help me find a heavy duty bike brake cable?PS I always stretch or rip the cables that I get from stores, and have asked about a heavy duty cable but they say I dont need one.

- step one: call a service station step two: pay them to do the job so you don't screw it up royaly step three: remember that i told you so! after you do screw it up -if you don't have a clue how to do it without the manual you shouldn't do it at all

- Q: I need to know the main components in a non-ABS system and also what they do/how they work.

- Pedal (pretty easy one) That is connected to a brake booster usually its a vacuum operated servo that assists your pedal power. then that is actuating the master cylinder which has a reservoir and a piston inside of it. That piston creates the hundreds of pounds of pressure to actuate the brake calipers (slave cylinders for disk) and/or drum brake slave cylinders. Of course there is rubber hoses and metal lines between the master and the slave cylinders. On disk brakes there is a piston in it that clamps down on the rotor disk (well the pads are touching are between it and the rotor) then on drum brakes there is a set of springs and arms but basically the slave pushes out on the brake shoes (pads) causing friction with the drum.

- Q: Hi engineers, i am student working on air brake system of trains.I wanted to know everything related to air brake you know.If possible please suggest a good website where i can find material related to air brake system.Thanks in advance...

- The air brake system is the same on hi way truck/ trains. It is a spring in an air pot, separated with a diagramThe brakes are spring applied, and air released. There are all sorts of valves in the system, to achieve different functions, relay valves, quick release valves, etc.

- Q: In particular, relating to -Speed of Response-Force Available-Supply of Operating Fluid-Weight of system

- Hydraulic systems utilize fluid to transmit force. Examples are brake systems, landing gear struts and (in more complex aircraft) flight control or landing gear actuator systems. Pneumatic systems utilize gas (usually air) to transmit force. Examples are gyroscopic instrument air systems and (in more complex aircraft) deice boot inflation systems. Since gasses are compressible, and fluids are not, hydraulic systems have a greater speed of response and transmit higher forces. Pneumatic systems are generally supplied by atmospheric air (pumped), or engine bleed air from the compressor sections of turbine engines. Hydraulic systems are supplied by on-board reservoirs and/or accumulators. Pumps are used to amplify control forces input by the pilot when higher forces are required to move an actuator. Pneumatic systems are generally lighter than hydraulic systems, due to the absence of fluid. If you are a student pilot or mechanic, please take time to go back and study these topics in your coursework. Go to an aircraft and touch these things. Look in the systems description section of any moderately complex aircraft POH or AFM. This kind of systems knowlege is very important to your confidence and safety when you are operating or maintaining an aircraft, especially when things go wrong. You really really need to be confident that you know how this stuff works.

- Q: from what I have learned from this forum, my buick regal has a leak in the braking system which causes my car to stop running after applying brakes. have already spent over $2,000 on other items and still just quits running and then wont start until it is jumped off.

- Light a match let it burn then blow it out while the doors and windows are closed so none of the smoke gets out. If tht don't work lots a fabreeze

Send your message to us

Good quality auto brake system brake pads manufacturer in china

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 300000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords