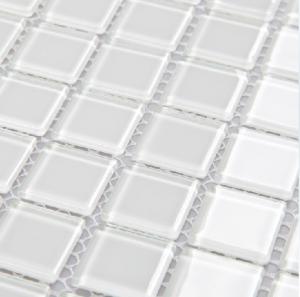

Glass Mosaic Pure White CMAX6500

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 x 20' FCL m²

- Supply Capability:

- 100000 M2 Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Key Specifications Of Glass Mosaic Pure White

NAME | Glass Mosaic Pure White |

ITEM DESCRIPTION | 1. It's a good decoration material for wall, kitchen, bathroom, floor and so on. |

SIZE | 1. PCS size in 23x23x4mm |

PACKING | 1.10 or 11 sheets in a carton |

FEATURES | 1. Produced in High temperature |

CHARACTERISTIC

| 1) Suitable for inside and outside walls, KTV,swimming pools, fountains and similar applications

2) Can be applied as complete sheets or in small sections to decorative borders or trims with other tiled surfaces

3) Resistant to fading, staining and discoloration, easy to clean

4) Acid-resistant and Alkali-resistant

|

APPLICATION | Floors, wall, countertops, showers, pool, backsplashes, living room, bathroom, dining room, kitchen, ceiling. |

ADVANTAGE | 1. Multi-Size Design |

INSTALLATION: | 1). Make sure the surface of the wall flat and clear. |

- Q: What is the tile?

- Tiles are what we often say floor tiles, is a ground decoration material, cheap, easy to clean up the cleaning. But with the wood floor than the foot feeling is not very good, hardness. At present, many home decoration will also use the tiles, usually used in the living room, kitchen put, bathroom, balcony and other occasions. 1) Whether the tile is solid and solid: We all know that the tiles should be solid and not easy to be damaged, especially when the weight is on top. 2) non-slip: the surface of the tile is relatively smooth, and some tiles are quintana bricks, glazed tiles, quintana polished tiles, tiles, seepage tiles, etc., these tiles are not anti-skid, the elderly and children with special attention , Try not to choose the tiles, but the choice of wood flooring. 3) to listen: we can pick up a brick gently beat, hear the sound of crisp is good quality tiles, the sound is muddy times defective. 4) test the water: we will pour the back of the tile on the water, after a few minutes, observe the degree of water immersion, if slow, and the watermark is not obvious, then is a good tile. 5) to find ink painted on the surface of the tile, over an hour or so, if the surface is no trace, then a good tiles, if the surface left traces, you must not buy. 6) Color: Do not choose the color difference of large tiles, should choose the color are all with the tiles.

- Q: What is the difference between tiles, tiles, tiles and tiles?

- Wall tiles and tiles are collectively referred to as tiles with tiles called tiles to tiles and polished tiles and glazed tiles is a glazed brick brick is a variety of tiles of samples that want tiles shop pendulum tiles are also divided into external tiles and tiles Interior tiles, modern tiles and antique tiles

- Q: Steno Tiles how Steno is a few lines of brand

- 3 look at the appearance Before looking at the appearance, we must first look at the store lights, light color, brightness is different, will cause a greater visual difference. If necessary, the floor tiles can be moved outdoors to carefully view the maximum degree of reduction of the original color of the tile. First of all, of course, is to choose their own favorite color, and then we must carefully look at the surface of the deficiencies and flaws. Look at the appearance of the most should pay attention to the tiles on the surface of the small flaws, this problem even big brands of tiles will appear. If the blemish is small, or rarely (a few tiles have one) is negligible. Appearance should also pay attention to the tiles of the corner there is no bump of the situation, the tiles of the glazed corner of the most fragile, glazed bad quality tile is the first corner of the problem. Of course, businesses certainly will not be broken brick can open two bags of tiles to see each corner of the situation, if only individual tiles have a corner of the bump, is acceptable, because in the paving, the experienced tile union Put such a brick on the ground edge, will be cut off the side of the problem, does not affect the use. 4 test weight The same size of the floor tiles, the greater the weight, the better the quality, which is a relatively simple and rugged and effective selection method. Good quality tiles (800mm * 800mm) a pack of three, not a regular exercise of adult men is difficult to move up alone. (I belong to the type of extreme lack of exercise, two Nobel 800mm * 800mm tiles I can not move a person) Weight reference: a 800mm * 800mm tile about 30 pounds to 40 pounds, a 600mm * 600mm tile about 12 pounds to 18 pounds, a 300mm * 300mm tile about 3 pounds to 5 pounds.

- Q: i‘m thinking about laying my own tile. ( this way i could save $2700) yeah, i know its a pain int he butt. BUT i‘m still going to do it because i like doing my own work. I‘m laying down 24x24 tiles. do you have any advice or secrete or techniques to offer? its a straight edge tile so i was thinking about using no spacers. I was also told to spread thinset on the tile in addition to the cement floor.

- 27 hundred dollars? What the hell are ya going to tile, a football field?..Ok, first I would think twice about not using spacers but that's up to you.. When you buy the tile check for the size notched trowel that's recommended and use it on the concrete floor and flat butter the back of the tile, and use a rubber mallet to tap it firm.

- Q: Which colour of tiles do you think suit white kitchen cabinets??

- Pretty much anything goes with white. Personally, for longevity, I would go with a soft sage green or gray-green tile or you might try the new glass tiles that have great shapes. Another great look would be a black and white pattern.

- Q: Do I start in the middle like normal tile? What happens if I don‘t start in the middle due to the uneven wall?

- Personally I would dtart in the middle just like you asked. Are you planning to lay the tile on wood subfloor or conrete? Wood is by far the best way to go as the glue will stick better. If its wood then make sure all is clean and dry the use a laytex primer on the wood and let dry. This step is a must as its the primer that will activate the glue and not allow the tile to pop off after install. If its concrete then again make sure you sweep then clean the floor with TSP( very strong chemical wear gloves) this will get all the junk that maybe on the concrete ie oil, dirt, paint, wax you name it. alolow to dry then install the tiles. If onto vinyl then use the TSP again and then put an embosser levelor on top of the existing vinyl floor as this will create a smooth floor and not allow your old vinyl pattern to show through you new tiles. the final step I like to use is a rolling pin over the tiles to make sure the glue is biting into the floor well.

- Q: Anyone know how much I should expect to pay to have a professional install ceramic tile flooring? The prep work has been done. The tile is 12 x 12, there‘s about 90 sq ft of floor (concrete... sealed). I‘ve purchased the materials (tile, thinset, grout). I just want to know how much to expect to pay for labor. Is $5.00 per sq ft. too much? That‘s the quote I was given. Thanks for any help.

- Do it yourself. It's easy. You'll have to buy another $70 worth of stuff at Lowes. Plus, a $90 wet saw (if you have complicated corner cuts). But then you'll know how to do it and have the tools to do it next time. Go for it !

- Q: How to choose bathroom tiles

- I do not know if there is no such decoration experience: most of the financial and material development are devoted to the living room and bedroom, alone ignored the bathroom, the final budget is not enough friends, bathroom wall had no choice but to hastily. Xiaobian home is like this, quoted a online encounter with the same encounter children's shoes: there have been a number of good tiles placed in front of me, I did not cherish, and now is regrettable. If God gave me a suite, I must raise the budget of the infinite unlimited, if you have to say a specific number, that is ten thousand yuan!

- Q: I like the original quarry tiled floor from our 60‘s kitchen, but they are quite badly stained. I can‘t pretend they have any historic value, or even were particularly well laid, so on balance should I1) Replace with new tiles, perhaps up to a higher standard2) Get a specialist to restore them to something approaching their original stateWhich will cost more, and what would you do?

- My opinion? Replace. I believe you would not be happy with the restoration since they were not laid properly in the first place. Doesn't matter which costs more if. in the end, you are unhappy with the results.

- Q: Also, formica or tile for a countertop???

- countertops are going more tile or granite anymore. depends on your taste and style your looking to achieve. if you are wanting a more expensive look, go for porcelein. very nice tile. if you have animals, dogs, i would not go with a white grout or a white floor. tile is less expensive in price but porcelein in rich looking.

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 2009 |

| Annual Output Value | US$ 1 Million - US$ 2.5 Million |

| Main Markets | 30.00% Domestic Market 20.00% Africa 20.00% South America 10.00% Eastern Asia 10.00% Mid East 10.00% Southeast Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Foshan new port, lanshi port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 50-100 People |

| Language Spoken: | English, Chinese, Spanish |

| b) Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average Highly |

Send your message to us

Glass Mosaic Pure White CMAX6500

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 x 20' FCL m²

- Supply Capability:

- 100000 M2 Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

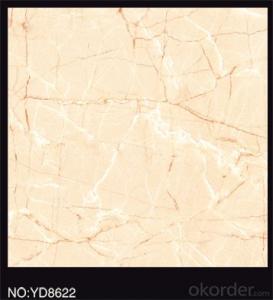

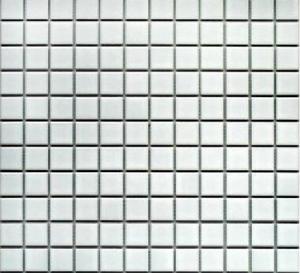

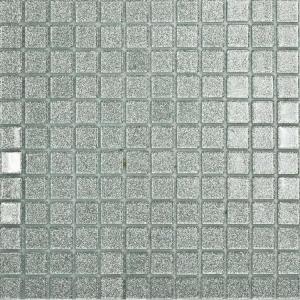

Similar products

Hot products

Hot Searches

Related keywords