GBF series fluorine plastic lining pipeline pump

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.GBF series fluorine plastic lining pipeline pump descriptions

GBF series fluorine plastic lining pipeline pump is made by fluorine plastic hot melt molding process, with particularly strong corrosion resistance of the new pipeline centrifugal pump. This pump impeller and motor straight via stent, choose bellows outer container type mechanical seal, shaft seal is stable and reliable, intuitive easy to adjust, hydraulic performance is superior, the suction uniform, over-current components using fluorine plastic materials(PEP, PFA ) manufacturing, decay resistance performance excellence.

Corrosion resistance, heat resistance, not aging, smooth operation, low noise, high efficiency, easy maintenance, long life and other advantages, widely used in acid and alkali, oil, chemical industry, electrolysis, electroplating, pickling, aluminum foil, rare earth, medicine, dyes, pesticides, flue gas desulfurization and dust removal, food, pharmaceutical and synthetic fiber industries.

Applicable temperature: 60℃~+150℃

2. Model sense

Ex: 50GBF-30

-50:Nominal diameter of inlet and outlet (mm)

-GBF:Fiourine plastic lining pipeline pump

-30:Pump head (m)

3. Design features

- The pump flow components application fluorine plastic hot melt moulding process combined into a whole, high mechanical strength;

- Has excellent corrosion resistance performance, transmission of all kinds of corrosive medium, such as acid, alkali, oxidant and organic solvent without damage;

-The pump is vertical structure, inlet and outlet diameter are the same, and is located in the center of a unified online, easy installation, use of a small area, the motor add a rainproof cover can be used outdoors;

- The impeller and motor direct dive, short axial dimensions, compact structure, smooth operation, high transmission efficiency, low noise and vibration;

- Shaft seal installed PTFE corrugated pipe mechanical seal, sealed and reliable, intuitive, and according to the characteristics of the media to provide a variety of materials friction pair selection, and has a wide application range;

- The use of the maintenance is convenient, only need to remove the pump body and the connecting frame fastening nut can be disassembled the rest, no need to remove the dynamic pipeline.

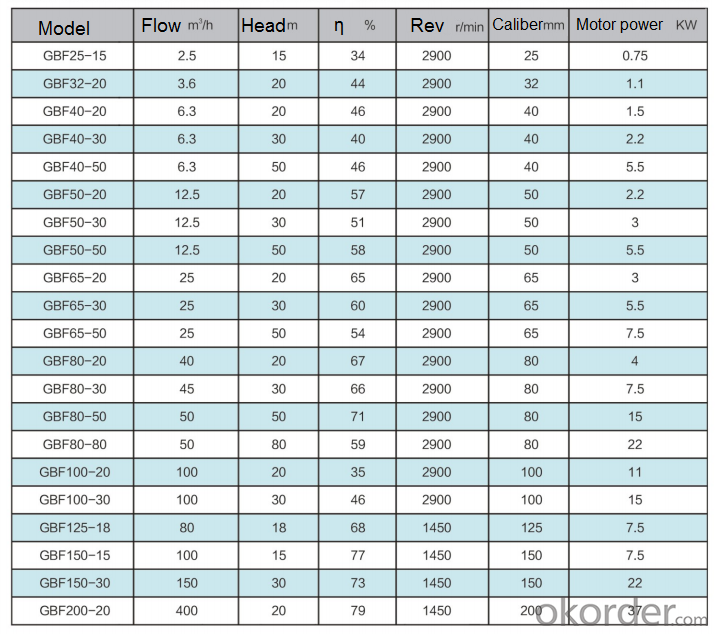

4. Technical parameters

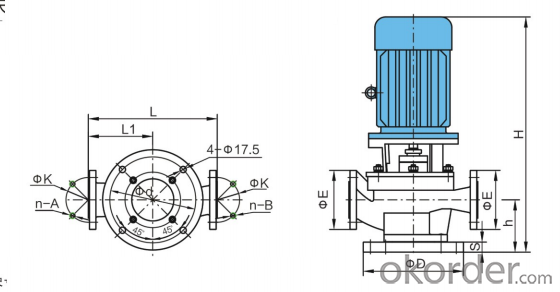

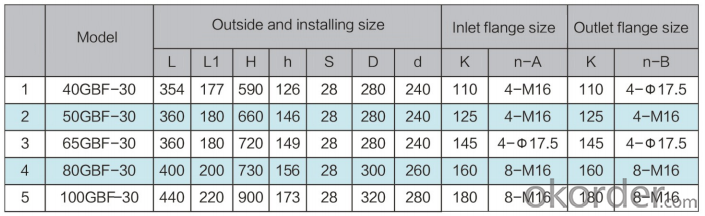

5. Install size / Flange size

- Q: The difference between submersible pumps and centrifugal pumpsWhat's the difference between the two? What is applicable and what?

- Difference:The installation position is different: one can discharge water, one is on the ground.The work principle is different: the principle of submersible pump is similar to the electric fan, centrifugal pump through centrifugal force to make the water throw out. According to the principle of centrifugal force design,

- Q: Why should I pump the pump before starting the centrifugal pump?

- Only centrifugal water can be pumped out of the centrifugal blade to generate negative energy at the entrance. There is no water diversion. Only the negative pressure produced by the air is too low to absorb the well water.Water pump has been pumped, centrifugal pump or can not start normally, mostly because of the water pipes and air

- Q: What kind of motor does the hydraulic pump need?

- First count the flow: Q=dn L / minD displacement / revN RPM / minThen calculate the actual power: N=QP/ (60K) kwQ flow L / minP MPa MPaK total efficiency (usually 0.85)

- Q: What is pump suction work?

- Pumping loss refers to the loss of work done by the piston of the engine in the pumping process compared with the theoretical cycle. Theoretical pump Qigong to remove the loss of pump gas after the actual pump qigong.

- Q: What is the function of the heating pump system for the water pump design?

- As the feed water temperature is higher, before starting, if not enough to warm the pump, the pump body temperature is uneven, there is a hot, cool phenomenon. The upper part is inflated and the lower part is inflated"

- Q: What is the working pressure of the hydraulic pump in the hydraulic transmission system?

- The operating pressure of the hydraulic system depends mainly on the load. Generally speaking, the working pressure of the hydraulic system means the highest working pressure of the system. If the pressure is higher than the value of the equipment, the relief valve works to relieve pressure. The actual working pressure of the hydraulic system is determined by the load, which refers to the actual pressure of the hydraulic oil and can be read directly from the pressure gauge. The pressure increases with the increase of the load. You Li's balance can know: the thrust of the cylinder = the load, the thrust of the cylinder = the working pressure of the hydraulic oil, the working area of the cylinder, the working pressure = the load / the area of the cylinder.

- Q: How high can the pneumatic diaphragm pump be?

- Pump made of polyvinylidene fluoride (PVDF) material two, the series of pneumatic diaphragm pump belongs to the fluorine plastic pneumatic diaphragm pump is also known as the corrosion products of pneumatic diaphragm pump, diaphragm liquid contact using PTFE material, using PVDF material produced by pneumatic diaphragm pump is mainly used in corrosive the pH, mainly used for chemical liquid conveying multiple solvent, corrosion resistance effect is very good. The series of fluorine plastic pneumatic diaphragm pump in high temperature less than 93.3 degrees.POM pump material also has good resistance to solvent and abrasion resistance, low friction resistance, moisture absorption is also low, the highest temperature of such pumps within 65.5 degreesPolytetrafluoroethylene (PTFE) membrane corrosion resistance is very good, in addition to liquid metal lithium, potassium fluoride, sodium fluoride, three chlorine, three fluoride high temperature oxygen, high flow rate, almost all of the chemical liquid transport (including concentrated nitric acid and aqua regia), PTFE material the maximum temperature to 176.6 degrees. However, for the diaphragm pump product as the diaphragm moves back and forth in work, we suggest that at a temperature of 120 degrees, the prerequisite is the pump body pump must be made of metal material and plastic material. The pump is the pump of PVDF material temperature is highest in less than 93.3 degrees.

- Q: Centrifugal pump flow, why can be adjusted through the outlet valve? Can the flow of the reciprocating pump be adjusted in the same way?. Why

- Reciprocating pump is a positive displacement pump, the volume change of flow is the unit of time, constant flow speed constant, can not rely on increased resistance to change the flow resistance increase is only leaked, only small changes in flow.

- Q: Why is the submersible pump tripped on an electrical switch?There is no electrical leakage protection, directly connected to the circuit breaker, and when the switch on, the circuit breaker jumpedI checked the line is good, the pump did not break down, is not the water pump?

- Calculate or refer to the water pump nameplate that the normal operating current, according to this data exchange switch.2) with 500V shaking table, measuring the cable, motor insulation is in line with the requirements

- Q: How to calculate the motor power of metering pump?

- The total mechanical power and hydraulic power, divided by the overall efficiency of pump, and the pump head and the utilization rate of pump mechanical efficiency, and then multiplied by 1.1 times (API675), you can get a metering pump motor need more power.

Send your message to us

GBF series fluorine plastic lining pipeline pump

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords