CQB series fluorine plastic magnetic pump

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CQB series fluorine plastic magnetic pump description

CQB series fluorine plastic magnetic pump, using magnetic coupling drive, without dynamic seal point, solving general shaft drive centrifugal pump seal outside run, drip problem. Flow components are using fluorine plastic and high purity of industrial ceramics, It has excellent corrosion resistance and seal ability, widely used in chemical, pharmaceutical, aluminum foil, acid, paint, and other non-ferrous metal industries and explosive, volatile, toxic transport, organic solvents and precious liquids.

Applicable temperature:-20C~100°C

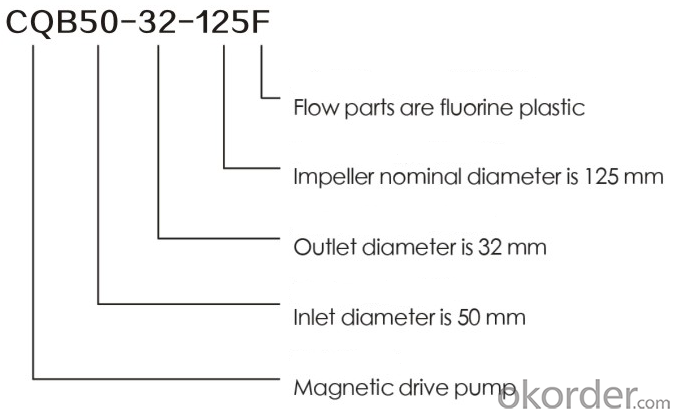

2. Model sense

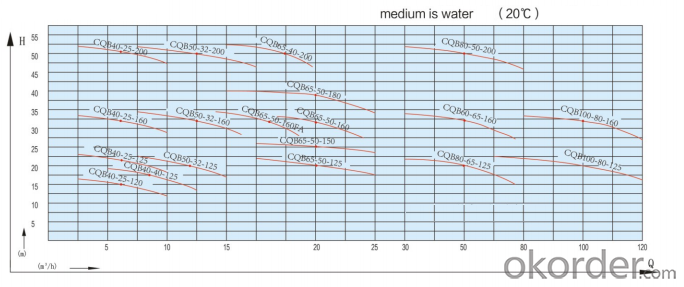

3. Performance curve diagram

Situation: The medium is water and n=2900r / min

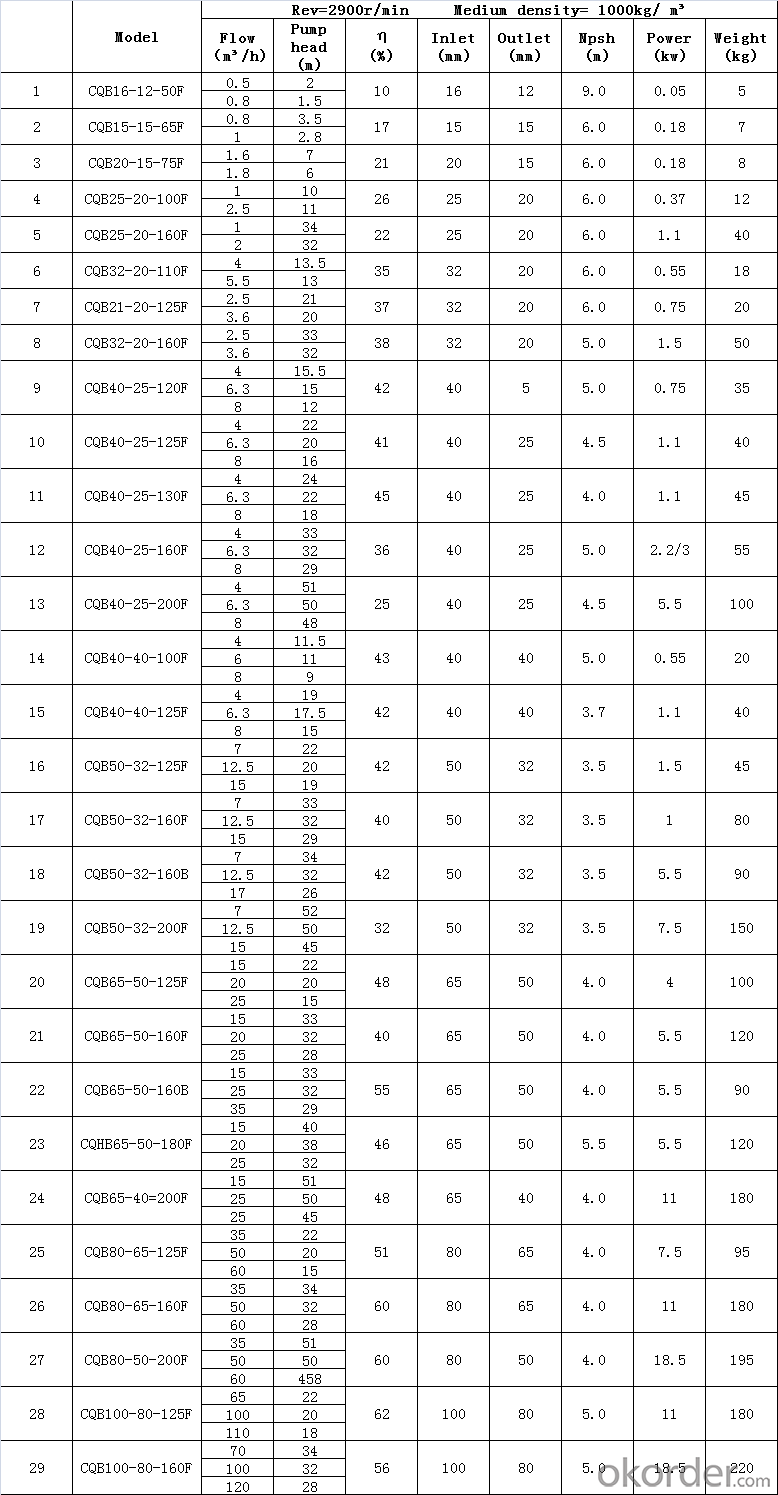

4.Model performance

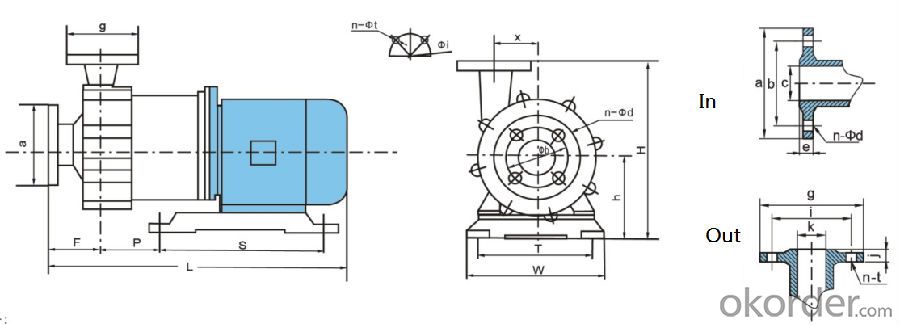

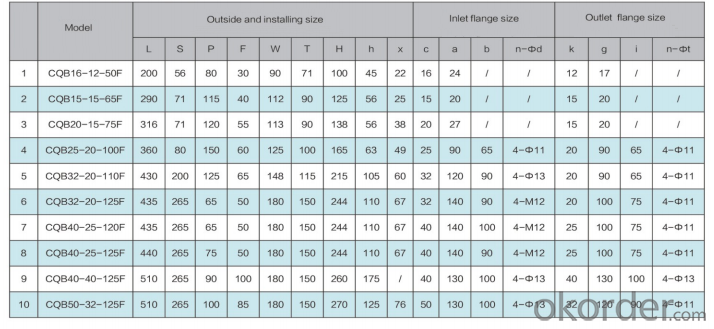

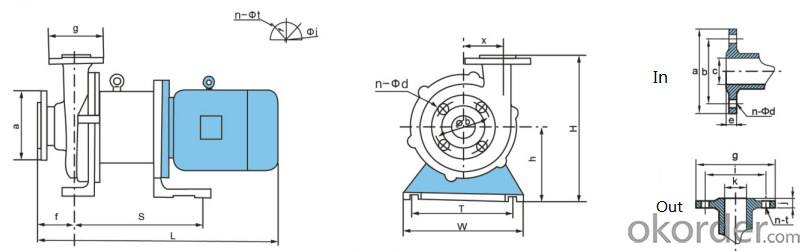

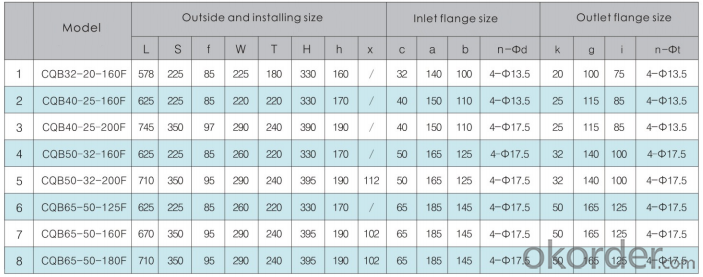

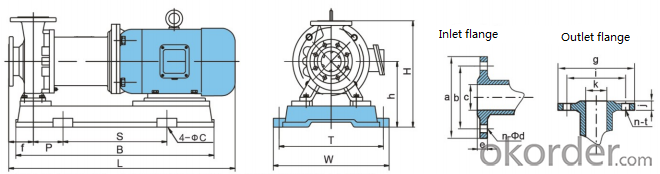

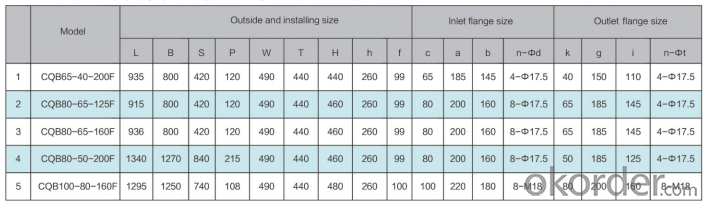

5. Install size / flange size

Type one:

schematic diagram

Data specification

Type two

schematic diagram

Data specification

Type three

schematic diagram

Data specification

6. Installation and maintenance Notes

-. Make concrete foundation in accordance with the basic size and embedded anchor bolts.

- Check the pump and motor before installation, all parts should be in good condition, no debris inside the pumps.

- Install the unit on the basis of concrete, put pairs wedge cushion between the base plate and foundation, through high-speed cushion, find the right horizontal position on the pump.

- The inlet and outlet pipe line should have a supporting foot, can't use the pump to stand pipe line. The inlet& outlet diameter of the pipeline and the inlet& outlet diameter of the pump should be same.

- After installation, turn the coupling by your hand and check whether if any rubbing.

- Magnetic pumps not allow to extract the medium which containing particles.

- In order to prevent debris entering the pump, should be located in the entrance filter, filtering area should be greater than the pipe cross-sectional area of 3-4times

- High head pumps should be installed back valve on the outlet pipeline, in order to prevent the sudden stop caused by water hammer damage.

-Must ensure that the installation height of pump in line with the pump NPSH and consider the pipeline loss and temperature of the medium.

- When the medium temperature is too high, the cooling measures should be taken, in order to prevent the machine seal deformation, static ring cracking.

- Q: Why should the pump be closed when the centrifugal pump is started?

- Centrifugal pump has an important characteristic: when the pressure (head) is very low, the flow will be great, which can be seen from the characteristics of the pump curve. While the pump power is directly proportional to the flow rate, pump start, no pressure in the pipeline, caused by the pump flow, high power pump, and the pump motor, the rotating part from rest to high-speed operation, need a lot of acceleration, it will cause a great starting current

- Q: What are the functions of a disposable infusion pump?

- When the transfusion is too slow, the dosage may not be enough, or the infusion time is prolonged unnecessarily, the treatment is affected, and unnecessary burden is added to the patient and the nursing work. In routine clinical infusion, the infusion of hanging bottle is generally used, and the speed of infusion is controlled by the use of a manual clamp. The speed of infusion is not easy to be controlled accurately, and the workload is great.Treatment of cancer patients with chemotherapy and critically ill patients need to make drug infusion rates constant, by adjusting the input speed and duration of chemotherapy drugs is continuously injected into the uniform, not only to achieve the best effect of chemotherapy, and to minimize the side effects of chemotherapy drugs.People suffering from diabetes need to inject a certain amount of insulin at a certain speed. The previous approach is basically a large dose of insulin injection, which not only caused a huge waste, and the effect of time is relatively short, so for a conveying device of flow and velocity control, to carry a small amount of drugs and precisely control the conveying speed and flow.Some special drug delivery to the elderly, children and physical weak, such as drugs, antihypertensive drugs, sodium nitroprusside (three TPN codehydrogenase) when the infusion rate and dosage should seriously control accurately, otherwise it will have serious consequences.

- Q: What should I pay attention to when buying a pump?

- Two, the first choice of large and medium-sized professional manufacturers, and through the quality identification of relevant departments, the market credibility of the better models, but also to the professional quality inspection institutions consultation.Three, check the motor grounding device for electric pump, water pump and motor axis, the motor should be in a proper position is provided with a grounding screw, and the grounding screw are arranged near the ground; grounding device of small submersible pump should be reliable and grounding wire, grounding wire cables should have the obvious grounding mark the flag should be in use; the motor is not easy to be worn during the period. This is one of the important safety indexes of electric pumps.

- Q: Does the reservoir water heater press the booster pump (high marks)?

- 60 liters of water storage should be able to drive two bathrooms at the same time bath! Water storage water heater generally does not need booster pump, as long as there is a little pressure, the water heater is filled with water, as long as the tap water can do. You can turn off the hot water valve and see only the amount of water in the cold water. If hot water is much smaller than cold water, it is the reason for the heater. Can you check the water mixer is normal, the one-way valve is installed in reverse.

- Q: What is the pump delivery? What's the difference between years and years?

- Secondly, the landlord asked the question, although I did not go to the insurance company to practice the operation, but to my four years of learning, as well as internship experience, or can help you analyze, and I hope to help you.Pay is a one-time payment of premium -- all wholesale D sea n

- Q: Hydraulic pump displacement refers to the pump shaft what?

- You can see the sign of your hydraulic pump. There will be a displacement **ml/r in the sign of the hydraulic pump (r stands for every turn, ML is milliliter)

- Q: Centrifugal pumps for normal operation, is it reasonable to install valves on their inlet lines? Why?

- Unreasonable, easy to produce throttling loss, pressure loss, pressure reduction, easy to cause cavitation

- Q: Because the water pressure of the booster pump is not enough, it can not work automatically. It can only be operated by hand. It is inconvenient to use.

- One possibility is the automatic type household booster pump used for a period of time, automatic failure phenomenon, it is mainly stainless steel and other metal products in pipes, long-term precipitation to shut off the power supply after unloading, unscrew the top screw, remove the plastic sheet to be cleaned, and then, according to the original reset, the normal debugging. Can be re used. But that's not why if your booster pump isn't working properly all the time.

- Q: What is the difference between an air pump and a water pump?

- Pump performance of technical parameters are flow, suction, lift, shaft power, water power, efficiency, etc.; according to the different principles of work can be divided into volume pumps, vane pumps and other types. Displacement pump is to use its studio volume changes to transfer energy; vane pump is to use the rotating blade and water interaction to transfer energy, there are centrifugal pumps, axial flow pumps and mixed flow pumps and other types.

- Q: Attention should be paid to the use of pumps?

- To carefully check whether there is a crack impeller, impeller fixed in the bearings are loose, if there are cracks and loose, hungry phenomenon should be promptly repaired, if the pump impeller above the soil should also be cleaned

Send your message to us

CQB series fluorine plastic magnetic pump

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches