Formwork Parts Scaffolding System Formwork System Parts

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Formwork Parts Scaffolding System Formwork System Parts

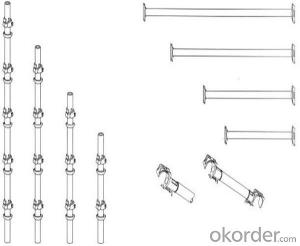

Product pictures:

Product description:

Name: | RingLock Scaffold System |

Category: | Scaffolding System |

Material: | Steel (Q235/Q345) |

Size: | D48*3.25mm, etc |

Surface: | Electro Galvanized, Hot Dipped Galvanized, Painted, Powder Coated |

Component: | Standard, Ledger, Diagonal Brace, Bracket, Base Jack, U Head Jack, Etc. |

Application: | Slab Support, Staircase, Stage Plateforms, Bridge Support, Mobile Tower, etc. |

Manufacturer: | OEM is Available |

Items or goods can be manufactured according to your standards. | |

Advantage

* Good loading capacity

* Easy to assemble and dismantle

* Excellent quality for formwork & scaffolding with wide choices

Other scaffolding & formwork products:

(1) Scaffolding System:

(2) Scaffolding Frame & Accessories:

(3) Scaffolding Couplers/Clamps:

(4) Formwork System Scaffolding & Accessories:

Company introduce and advantages:

1. A state-owned company, prestige fi rst.

2. One of Fortune 500 companies in the world. No. 5 in the building material fi eld.

3. Six Sigma strategy , which means no more than 3.4 defects existing among one million of error

possibilities.

4. In line with the business, we launched E-business platform Okorder.com.

5. We are highly recognized by our business partners and clients all over the world and has obtained rapid

development under the spirit of win-win.

FAQ

Why Us?

We are one of the largest construction materials suppliers in China.

We own professional manufacturers with powerful producing capacity.

Extensive and comprehensive quality control system

Excellent products with competitive prices.

Efficient services in pre and after sale.

Full energy with affluent experience team.

- Q: How does steel frame formwork handle different types of formwork joint arrangements?

- Steel frame formwork is a versatile and robust system that can handle different types of formwork joint arrangements with ease. This type of formwork is designed to be adjustable and flexible, allowing for various configurations and combinations of joints. One common type of formwork joint arrangement is the butt joint, where two formwork panels meet end-to-end. Steel frame formwork is designed with special connectors and clamps that securely hold the panels together, ensuring a tight and seamless joint. These connectors are adjustable, allowing for precise alignment of the panels to achieve the desired formwork shape and dimensions. Another type of joint arrangement is the corner joint, where two formwork panels meet at a 90-degree angle. Steel frame formwork is equipped with corner connectors that securely hold the panels together at the desired angle. These connectors are adjustable as well, allowing for precise alignment and ensuring a strong and stable corner joint. In addition to butt and corner joints, steel frame formwork can also handle other types of joint arrangements such as T-joints, cross joints, and Y-joints. The adjustable connectors and clamps of steel frame formwork enable easy assembly and disassembly of the panels, making it possible to create various joint configurations as required by the specific formwork design. Furthermore, steel frame formwork provides excellent stability and load-bearing capacity, making it suitable for handling different types of joint arrangements even in complex and demanding construction projects. The steel frames and panels are designed to withstand the pressure and forces exerted during the concrete pouring and curing process, ensuring the integrity and strength of the formwork joints. Overall, steel frame formwork is a reliable and efficient system that can handle different types of formwork joint arrangements. Its adjustable connectors and clamps, along with its stability and load-bearing capacity, make it a preferred choice for various construction applications.

- Q: How does steel frame formwork handle the construction of stairs and ramps?

- Steel frame formwork is an excellent option for constructing stairs and ramps due to its strength, durability, and flexibility. Comprised of steel panels, props, and connectors, the system can be easily assembled, adjusted, and dismantled according to the specific needs of stairs and ramps. During the construction of stairs, the steel frame formwork is specifically designed to bear the weight of workers and materials while concrete is poured and cured. The high-quality steel panels offer exceptional structural stability, ensuring the safety and stability of the staircase. Furthermore, the formwork system can be customized to create various types of stairs, including straight, spiral, or curved designs. Similarly, when constructing ramps, the steel frame formwork provides numerous advantages. Its adjustable props allow for the creation of ramps with different heights and slopes, making it suitable for various applications such as car parks, pedestrian walkways, or wheelchair access ramps. The system's versatility enables the construction of ramps with different configurations and dimensions. Moreover, the steel frame formwork system can be easily modified to accommodate architectural features like landings, handrails, and balustrades in the construction of stairs and ramps. This adaptability ensures that the final structure meets the desired design and functionality requirements. In summary, steel frame formwork simplifies and streamlines the construction process of stairs and ramps by offering a strong and versatile solution. Its strength, durability, and adaptability make it an exceptional choice for creating secure and dependable access points in buildings and infrastructure projects.

- Q: How does steel frame formwork handle different types of concrete curing temperatures?

- Steel frame formwork is highly versatile and capable of handling different types of concrete curing temperatures. The steel frame provides excellent strength and stability, allowing it to withstand both high and low curing temperatures without warping or distorting. Additionally, the steel material has good thermal conductivity, which helps in efficiently distributing heat during curing. This ensures that the concrete cures evenly and achieves optimal strength and durability regardless of the curing temperature.

- Q: Can steel frame formwork be used for both insulated and non-insulated wall construction?

- Yes, steel frame formwork can be used for both insulated and non-insulated wall construction. Steel frame formwork refers to a system of temporary molds or structures that are used to hold concrete in place during the construction process. These formwork systems are versatile and can be adapted to accommodate different construction requirements, including both insulated and non-insulated wall construction. For insulated wall construction, steel frame formwork can be used to create a mold that accommodates the insulation material, such as foam boards or panels. The formwork system can be designed to include additional features, such as channels or slots, to securely hold the insulation material in place. The concrete is then poured into the formwork, encasing the insulation and creating a strong and insulated wall. For non-insulated wall construction, steel frame formwork can be used in a similar manner, but without the need for accommodating insulation material. The formwork system is simply used to create the mold for the concrete, allowing it to be poured and shaped into the desired wall structure. In summary, steel frame formwork can be used for both insulated and non-insulated wall construction by adapting the design and features of the formwork system to accommodate the specific construction requirements.

- Q: How does steel frame formwork handle the placement of façade cladding and curtain walls within the concrete structure?

- Steel frame formwork is a versatile system that is specifically designed to handle the placement of façade cladding and curtain walls within a concrete structure. It provides a robust and stable framework, ensuring that the cladding and curtain walls are securely attached to the building. One of the key advantages of steel frame formwork is its ability to accommodate the weight and movement of the cladding and curtain walls. The steel frames are designed to be strong and durable, capable of withstanding the loads imposed by the cladding materials. This ensures that the façade remains intact and secure, even in extreme weather conditions. Moreover, the steel frame formwork system allows for precise placement of the cladding and curtain walls. The frames are erected and aligned to the desired position, providing a level and straight surface for the installation of the façade elements. This accuracy is crucial for achieving a seamless and visually appealing final result. Additionally, steel frame formwork offers flexibility in terms of design and customization. The frames can be easily adjusted and modified to accommodate different types of cladding and curtain wall systems. This adaptability allows architects and designers to incorporate unique and innovative façade elements into the concrete structure, enhancing the aesthetic appeal of the building. Furthermore, steel frame formwork provides efficient installation and construction processes. The frames are lightweight and easy to assemble, resulting in reduced labor and construction time. This not only saves costs but also ensures timely completion of the project. In conclusion, steel frame formwork is an ideal solution for handling the placement of façade cladding and curtain walls within a concrete structure. Its strength, precision, flexibility, and efficiency make it a reliable choice for architects, engineers, and contractors looking to achieve a high-quality and visually striking building envelope.

- Q: Are there any specific considerations for using steel frame formwork in coastal areas?

- Yes, there are specific considerations for using steel frame formwork in coastal areas. The primary concern is corrosion due to the high salt content in the air and water. Special corrosion-resistant coatings or stainless steel should be used to prevent the steel frame from deteriorating. Additionally, the formwork should be designed to withstand the strong winds and potential impact from waves or debris in coastal areas. Regular maintenance and inspections are also necessary to ensure the structural integrity of the steel frame formwork in these harsh environments.

- Q: How does steel frame formwork handle extreme weather conditions?

- Steel frame formwork demonstrates exceptional durability and can endure the most severe weather conditions. Its robust and steadfast structure guarantees its integrity, even in the face of inclement weather such as heavy rainfall, strong gusts, or extreme temperatures. A primary benefit of utilizing steel frame formwork lies in its resistance to corrosion. Steel, as a material, possesses an inherent resistance to rust, rendering it ideal for construction undertakings in regions characterized by high humidity or regular exposure to water. This resistance to corrosion ensures that the formwork remains structurally sound and maintains its integrity, even when confronted with adverse weather conditions. Additionally, steel frame formwork is designed to offer exceptional stability and load-bearing capacity. Consequently, it can endure high wind velocities without succumbing to damage or deformation. The robust nature of the steel frame formwork ensures that it can withstand extreme weather conditions without compromising the safety of the construction site. Furthermore, steel frame formwork is frequently designed with a protective finish or coating that further heightens its resistance to weather elements. This protective layer provides supplementary safeguards against moisture, UV rays, and other environmental factors, thereby prolonging the lifespan of the formwork and guaranteeing its durability in the face of extreme weather conditions. In conclusion, steel frame formwork proves to be an outstanding choice for construction ventures situated in areas prone to severe weather conditions. Its resistance to corrosion, stability, and protective finishes establish it as a dependable and long-lasting solution, capable of effortlessly handling even the most challenging weather conditions.

- Q: Can steel frame formwork be used for high-rise construction projects?

- Yes, steel frame formwork can be used for high-rise construction projects. Steel formwork systems provide a sturdy and durable option for constructing high-rise buildings. They offer high load-bearing capacity, which is essential for tall structures that require strong support during the pouring and curing of concrete. Steel frame formwork is designed to withstand the pressure exerted by the weight of concrete and other construction materials. The steel frames are built to be rigid and stable, ensuring the formwork maintains its shape and position even under heavy loads. This is particularly important for high-rise buildings, where the formwork needs to withstand the vertical pressure created by the height of the structure. Additionally, steel formwork systems can be easily adjusted and assembled to accommodate various shapes and sizes of high-rise buildings. The modular nature of steel formwork allows for flexibility in design and construction, making it suitable for complex architectural designs and layouts. Moreover, steel formwork is known for its reusable nature. Once a high-rise construction project is completed, the steel frames can be dismantled, cleaned, and used again for future projects. This not only saves costs but also reduces construction waste and promotes sustainable construction practices. In summary, steel frame formwork is a suitable choice for high-rise construction projects due to its high load-bearing capacity, rigidity, adaptability, and reusability. It provides a robust and efficient solution for constructing tall buildings while meeting the unique requirements of such projects.

- Q: How does steel frame formwork affect the overall durability of a concrete structure in harsh environments?

- Steel frame formwork can significantly enhance the overall durability of a concrete structure in harsh environments. The use of steel as a formwork material provides several advantages that help mitigate the adverse effects of harsh conditions. Firstly, steel is known for its exceptional strength and durability. It can withstand heavy loads and extreme weather conditions, making it highly resistant to damage. This strength allows the steel frame formwork to support the weight of the wet concrete during the pouring and curing process, ensuring proper alignment and preventing any deformation or collapse of the structure. Secondly, steel is resistant to corrosion, which is a common concern in harsh environments such as coastal areas or places with high humidity. The steel frame formwork acts as a protective barrier, shielding the concrete from exposure to moisture, saltwater, chemicals, or other corrosive elements. This prevents the deterioration of the concrete over time, ensuring its long-term durability. Furthermore, steel frame formwork provides excellent dimensional stability. It minimizes the risk of warping, cracking, or other deformations that can occur due to temperature variations, moisture content, or shrinkage of the concrete. This stability contributes to the structural integrity of the concrete, ensuring that it maintains its strength and functionality over time. Additionally, steel formwork allows for precise and accurate construction. The steel frames are designed to provide a stable and rigid structure, ensuring that the concrete is poured and compacted evenly throughout the formwork. This results in a more uniform and durable concrete structure, with fewer imperfections or weak points. Overall, the use of steel frame formwork greatly enhances the overall durability of a concrete structure in harsh environments. Its strength, corrosion resistance, dimensional stability, and precise construction capabilities contribute to the long-term structural integrity and functionality of the concrete, making it a reliable choice for projects in challenging conditions.

- Q: How does steel frame formwork contribute to better concrete consolidation?

- Steel frame formwork contributes to better concrete consolidation in several ways. Firstly, the steel frame provides a rigid structure which ensures that the formwork remains in place during the pouring and curing process. This stability prevents any movement or deformation of the formwork, allowing the concrete to settle and consolidate properly. Secondly, steel frame formwork is designed with built-in vibrators or vibratory systems. These vibrators are strategically placed along the formwork to help distribute the concrete evenly and remove any air pockets or voids. The vibration action also helps to compact the concrete, improving its strength and durability. Furthermore, the steel frame formwork allows for easy and precise placement of reinforcement bars or mesh within the formwork. This ensures that the reinforcement is properly embedded within the concrete, enhancing its structural integrity and preventing any potential cracks or failures. Additionally, steel frame formwork provides a smooth and uniform surface for the concrete. This smooth finish allows for better adhesion between the concrete and any subsequent layers or finishes, such as plaster or paint. It also reduces the need for additional surface treatments, saving time and costs. Overall, the use of steel frame formwork greatly enhances the consolidation of concrete by providing stability, facilitating vibration, ensuring proper reinforcement placement, and creating a smooth finish. These factors contribute to the production of high-quality and durable concrete structures.

Send your message to us

Formwork Parts Scaffolding System Formwork System Parts

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords