Fiber Cement Board Without Asbestos Green China

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Technical Data

Item | Index | Unit | ||

Density | ≤1.40 | g/cm3 | ||

Water contain | ≤10 | % | ||

Water absorption | ≤39 | % | ||

Incombustibility | Grade A1 incombustible | |||

Bending strength | Oven dry | cross | ≥12 | M pa |

Parallel | ≥10 | M pa | ||

Quick Details

Place of Origin: Guangzhou, China

Brand Name: CMAX

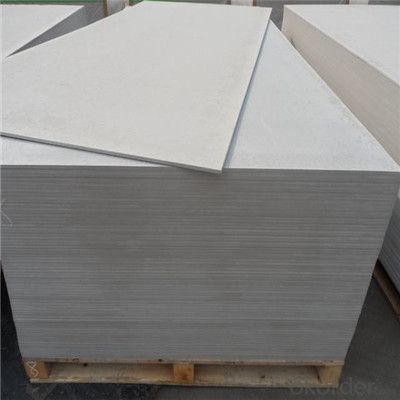

Density: More than 1.2g/cm3

Application: Ceiling ,Wall panel, Floor, partition

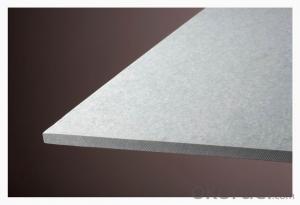

Specification: 2440*1220mm(Length*Width)

Thickness: 6/7/8/9/10/12/18/25 mm

Advantage: Easy-installing, Eco friendly

In-combustibility: GB8624-1997 Grade A1

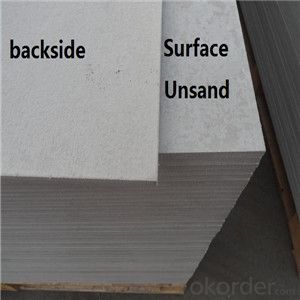

Without Asbestos Fiber Cement Board

Fiber cement board, using high quality fiber and mineral substances as main content,was made with forming by advanced technique & technological process & through high temperature & high pressure maintenance & special treatment.

Sound and Weather Resistant:

Karmeen fiber cement boards deliver optimal sound and weather insulation. Noise as well as changing weather conditions such as freeze / thaw, heat and water pose no threat to fiber cement board. The boards retain their shape at all times.

Low Maintenance:

The ability of the boards to resist mold and algae attacks is equally impressive. The result is a long-lived façade that saves you time and effort on inconvenient and costly repairs and repaints.

Non-combustible:

The boards are non-combustible, which is your guarantee for a safe building.

Easy Handling:

Karmeen fiber cement boards are flexible and easy to handle. They can be delivered cut to size, ready for installation. All this makes for lower construction costs, shorter construction times, and lower installed costs.

- Q: I need to cut a curved piece of cement board. Will it work to score it with a utility knife, then break it? Thanks.

- Yes it cuts just like drywall, scrore then snap.Score a bit deeper though.

- Q: Is the fiber cement board harmful to the human body?

- At present, most of the manufacturers of reinforced materials are made of rock wool, and rock wool on the construction process of cutting workers will have carcinogenic effects, so the fiber cement board will be harmful, but not all, and now we are studying cotton-free, if There is a need to try to find no cotton like

- Q: Hi, I have an outside breezeway that connects from my house to my garage with a roof and cement slab. I'm in the process of closing it in and making it part of my house(fully heated). I'm going to tile the floor but I'm not going to have a sub floor to insulate under it, I worry about moisture, cold floor and cracking of tiles (I live in Michigan).So my question is I'm not sure on how to go about this, I was thinking a 1/4 to 3/8 insulation rolled on the slab, then cement board and then thermostat controlled heating mat then tile, What do you think, thanks.

- I agree with William, use a rigid insulation rather than a roll insulation. It would be pretty much impervious to moisture. A roll insulation would eventually hold any moisture and get moldy and lose any r-value.

- Q: Is the cement board sound insulation effect is good, or gypsum board noise effect is good?

- Can not completely say that drops, in essence, the two almost no correlation, with the thickness of the material, density, and environmental accessories, etc. are still very different.

- Q: could someone please recommend (a) thin set, manufacturer, brand, this is a bathroom application. perhaps a Lowe's or home depot product.

- Custom Building products, sold at Home Depot is what I ve used for years.. You can use the white or grey, just that the grey is just a bit cheaper too. For porcelains you ll want the Flexbond line in the Custom thin set. It s the one recommended for porcelains. Also in the past I ve used H B Fuller s Tec lines of thin sets. love that line, it mixes to a nice creamy consistancy. But its not as available to the public and more expensive. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: My husband fixed the faucet in the tub around two years ago. He cracked one of the tiles. We bandaged the area, but water has been getting behind the tiles. So, we have water damage. Plus, there is this weird white fungus looking stuff that is growing in some of the grout lines. I don't want to just put a liner over this mess. I would like to pull all the tile off and put cement board up (the house is old and it has sheet rock behind the tile), so i can start fresh. Will the liner hold up the same if it is glued to cement board rather than tile?

- Tear out all the tile AND the drywall. Like some said above remove and replace any wet insulation and spray area with bleach water to kill mold. Consider getting a tub liner that can be attached directly to the framing around the tub then you don't have to worry about cement board. Make sure your husband caulks well so no more leaks (or hire a professional) That's what I did in our bath room. They are very easy to install. You then have the option of finishing around the top and sides of the liner with greenboard that you can paint, or I installed cement board and am tiling.

- Q: 5mm cement fiber board how much money a square?

- Beijing here is about 20-40 per month, is not tax with the freight, do not know which area you want,

- Q: We are remodeling our Bath and have put cement board around the shower which we will tile. My question is, do I continue to use cement board around the remainder of the bath or put up green board. The cement board in only 1/4 inch. Can I get greenboard that is 1/4 in. thick? I don't want a ridge between were the two meet. The tile will run half way up the wall and the other half painted in the remaining part of the bath.

- challenging problem. look at google or bing. this may help!

- Q: What are the standards for residential steel structures?

- For a long time, China's residential structure to brick and concrete structure and reinforced concrete structure. The traditional residential structure from the major, at the same time, due to the wall thickness, beam height, large column, and makes the space utilization is low, the opening depth is small, the arrangement is not flexible.

- Q: What are the risks if we do not install cement board first, if any?

- if your subfloor is a solid peice with no seams in that area and the floor itself is solid you should be ok but if there is movement your tiles and or grout could crack if it wouldnt make the tiles too high you better off using the cement board

Send your message to us

Fiber Cement Board Without Asbestos Green China

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords