Fiber Cement Board Cement Board Hot Sale Asbesto Free

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

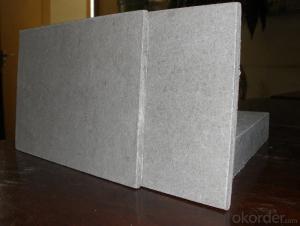

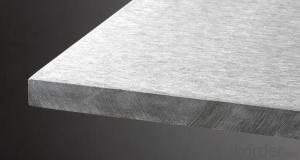

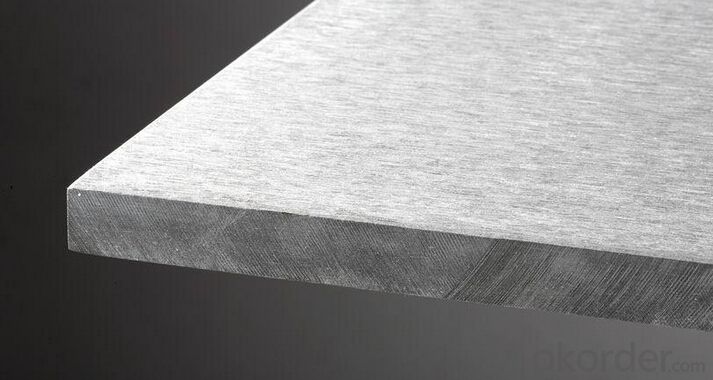

High Density and Strength fiber cement board is a high quality calcium silicate architectural board reinforced with selected cellulose fibres and fillers.

The raw materials of fiber cement board are cellulose fiber, silicate cement, quartz sand, water and some additives.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

Main Product Features:

It's 100% free of asbestos, formaldehyde, benzene and other harmful substances and with excellent performance like high strength, large size, light weight, fire and water proofing, green and environmental friendly, high efficient and energy-saving. Therefore, this kind of new material is vigorously developed and recommended by the country.

Product Specifications:

FAQ:

1. Q:What is the different and most important point from other supplier?

A:We guarantee No asbestos if it has asbestos density will be more than 1.4g/cm3 what's more

3.2mm*3000*1220mm can be produced by us other suppliers can not do this size

2. Q:What are the advantages of your board?

A: outstanding light weight ,heat insulation, waterproof, fireproof, sound insulation, fast construction.

3. Q: Is the board fire resistant?

A: Yes, fire resistant 4 h , in the heat of 1000℃.actually it is noncombustible Class A1.

4. Q: Do you have any certificate to help us get government's approval?

A:China testing report and our laboratory' s testing by ourselves as your supporting document.

Because building standards are different in different countries, most of our customers buy the boards for testing and get approval by themselves.

Images:

- Q: This building was previously a school building, with cement block walls..I need to know if I need backer board, or do I just need to fill in the low spots to make the wall flat and level? Also, what kind of thinset do I need for clear glass mosaics?

- You don t need a backer board.. As long as the block is solid and no cracks ( they need to be treated specially) you can go right over the block with a few precautions. The block needs to be clean and smooth. No mortar from the joints and stick out. If the walls are unpainted ( and clean) you can go over them with WHITE and white only thin set.There is no such thing as colored or tinted thin set.And glass tiles call for a strong latex modified thin set If the walls are painted ( and clean) you can use a mastic or the special thin set. Fill in the mortar joints with the adhesive you use. Mastic cannot be used if this is a wet area or going to be a wet area. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: i have an old cement wall house, i have tar paper on the outer walls and plan on putting 1 or 1 1/2 thick ridge insulation on the walls. These are above grade walls not basement.My question is do i have to vapor barrier the walls or just tape the seams of the foam insulation.thanks in advance

- If you already have tar paper (roofing felt, I presume), thats a vapor barrier. You don't need another. You can caulk the joints between the boards if you'd like.

- Q: I'm removing a tile floor and planning to install a hardwood floor instead. I found cement backer board under the tile. Do I need to remove the cement backer board? Or can I install the hardwood on top of that?

- Depends. If it is nail down flooring, not good. If it is snap together floating flooring, no problem.

- Q: I know I could hire someone with a curbing machine, but it is way more expensive than I want to pay and I want to do it myself so I can customize it to my yard. I've known people who have been able to do it themselves.What tools do I need?

- You will need something to shape the area. If curved, use some kind of flexible, cheap flower bed border stuff, and use boards if straight. I did my own cement work earlier this summer, and girl, make sure all your muscles are in shape! Be sure to stir it real well, then pour. I love cement!

- Q: I want to put a cork bulletin board outside my store but it's a cement wall and I do not want to ruin the cement wall.

- go buy a tap con kit. It consists of a drill bit for the concrete, concrete screws and a driver. It should only cost a few dollars. drill pilot holes in the cork, drill the concrete and fasten it with the blue screws made for concrete, you may want to paint the screw heads to blend afterward.

- Q: My fear is that I will trap moisture where it shouldn't be. Is there such a thing as overkill?

- Tile council of America calls for a vapor barrier behind the cement board ..The red guard your talking about should and must be used on any horizontal surface in a wet area.. There are other agents like red guard but I v used it many times and had great luck w/ it..Making sure the proper pitch is used for the horizontal surface GL

- Q: We have drywall in our kitchen that was painted with a smooth semi-gloss paint a good 8 yrs ago. We'd like to install 3x6 tumbled marble as a backsplash over the drywall. It's about 1/4 thick so probably slightly heavier than say, the tiny square glass tiles that come on a 12x12 netting. One person at the Home Depot said we could just sand and scrape up the drywall and then apply the thinset and install the marble. Another said we might want to use a cement backing. We aren't really DIYers and would so we don't want to create extra work with the cement backing if it isn't needed. That said, we don't want the drywall to start peeling and the marble tiles to start falling off after a short amount of time. Please advise. Thank you!

- ild install a 1/4' hardyboard board first -the thinset will not last sticking the tiles to the paint

- Q: Fiber cement board and the difference between the water board

- Water board with anti-ultraviolet radiation, acid and alkali corrosion and mild characteristics, soft texture, light, durable, can be bent, rich colors and many other features, often used in the field of architectural decoration.

- Q: Thanks Alex. How much you think I should charge to install each 4x8 sheet of cement board?

- I used to charge 2.50$ a s/f to install board or prep an area. That would include the board , thin set and nails ( or screws)to do it properly. 4x8 cement board is hard to find and heavier the all HE!!, so hire a friend. 3x5 sheets are much easier to handle by yourself. Any questions you can e mail me through my avatar. GL

- Q: What is the difference between VIVA wood chips and FOREX plum cement board?

- Color VIVA wood fiber cement board: the color is darker, (clear water color) FOREX US rock cement board: lighter color. (Water color)

Send your message to us

Fiber Cement Board Cement Board Hot Sale Asbesto Free

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords