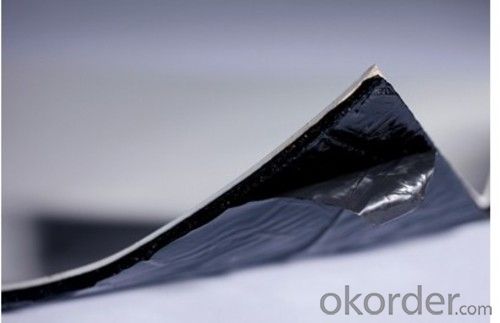

EPDM Waterproofing Membrane Used in Roofing Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

Tensile Strength N/CM | Normal temperature: 60 ; 60°C: 30 |

Breaking Elongation % | Normal temperature: 400 ; -20°C: 10 |

Tear Resistance N | 20 |

Impermeability, 30 min no leakage | 0.3Mpa |

Low Temperature Bending °C | -20 |

Heating Shrinking mm | Extension: 2 Shrink: 4 |

Heat Resistance (80°C×168h) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:70 |

Alkali resistance (10% ca (oh)2 solution,normal temperature ×168h)) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Synthetic aging | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Characteristic:

1.Excellent anti aging performance ,service life up to 50 years.

2.High extension rate,high tensile strength ,small size changes at heat treatment.

3.Good plant roots penetrability resistance and can be made waterproofing layer of planting roof.

4.Special modified molecular structure ,effectively resolving the current domestic and foreign glue joint problem.

5.Good low temperature flexibility ,and good performance of adapting to ambient temperature changes.

6.Convenient application ,solid joint ,no environment pollution.

7.Chemical corrosion resistance ,can be used for special occasions.

8.Good anti-perforated.

Applicable scope:

1.0mm 1.2mm 1.5mm 1.8mm 2.0mm EPDM waterproof membrane is widely used in roofs, basement, toilet, swimming pool, and all kinds of industry and civil building waterproofing, reservoir, bridge, underground, tunnel and dam waterproofing, especially to the keystone waterproofing projects which is durability, high corrosion resistance and easy deformation.

FAQ of Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q:Can a waterproofing membrane be used on green roofs?

- Yes, a waterproofing membrane can be used on green roofs. In fact, it is an essential component of the green roof system. A green roof is designed to have vegetation and soil on top of a waterproofing layer, which prevents water from seeping into the underlying structure. The waterproofing membrane acts as a barrier, protecting the roof and building from moisture damage. It ensures that water is properly drained and does not cause leaks or structural issues. However, it's important to select a waterproofing membrane that is specifically designed for green roof applications, as it needs to be able to withstand the unique demands of a green roof environment, such as root penetration and constant exposure to moisture.

- Q:Can a waterproofing membrane be used for a tunnel?

- Yes, a waterproofing membrane can be used for a tunnel. A waterproofing membrane is a material or system that is designed to prevent the penetration of water into a structure. In the case of a tunnel, where there is a high risk of water ingress due to the surrounding soil or groundwater, a waterproofing membrane can be applied to the walls, floor, and ceiling of the tunnel to provide a protective barrier against water infiltration. The waterproofing membrane is typically made of a durable and flexible material, such as bitumen, PVC, or polyurethane. It is applied to the tunnel surfaces in multiple layers, ensuring a continuous and seamless seal. This membrane acts as a barrier that prevents water from seeping into the tunnel, protecting the structural integrity of the tunnel and enhancing its lifespan. In addition to providing waterproofing, a membrane can also offer other benefits to a tunnel. It can provide protection against chemicals, such as chloride or sulphate ions, which can cause corrosion in concrete structures. It can also act as a vapor barrier, preventing the migration of moisture from the surrounding soil into the tunnel. It is important to note that the selection and installation of a waterproofing membrane for a tunnel should be done by experienced professionals who understand the specific requirements and challenges of tunnel construction. The design and application of the membrane must take into account factors such as the geological conditions, water pressure, and expected traffic load on the tunnel. Overall, a waterproofing membrane can be effectively used for a tunnel to provide protection against water ingress and ensure the long-term durability of the structure.

- Q:Are waterproofing membranes resistant to acid exposure?

- Yes, waterproofing membranes are generally resistant to acid exposure. They are designed to provide a barrier against water and other corrosive substances, including acids. However, the level of resistance may vary depending on the specific type and quality of the membrane used.

- Q:Can a waterproofing membrane be used on stainless steel surfaces?

- Yes, a waterproofing membrane can be used on stainless steel surfaces. Stainless steel is a durable and non-corrosive material that is commonly used in various industries. However, it is not completely immune to water damage or corrosion, especially in harsh environments. Applying a waterproofing membrane on stainless steel surfaces can provide an additional layer of protection against moisture, preventing potential water damage, rusting, and corrosion. It is important to ensure that the waterproofing membrane is compatible with stainless steel and applied correctly to ensure proper adhesion and long-lasting protection.

- Q:Can waterproofing membranes be used on terraces?

- Terraces can definitely benefit from the use of waterproofing membranes. In fact, it is highly recommended to apply these membranes to protect the terrace's structural integrity and prevent any water damage. Waterproofing membranes act as a barrier, effectively stopping water from seeping into the terrace and causing undesirable leaks or cracks. They are commonly utilized on flat terraces, rooftop terraces, and even balconies to guarantee that water does not infiltrate the surface and cause harm to the underlying structure. Waterproofing membranes come in a variety of types, including liquid-applied, sheet, and self-adhesive membranes, offering diverse options that cater to the specific needs of the terrace. By applying a waterproofing membrane, the terrace can be safeguarded against moisture, UV rays, and other environmental factors, ultimately prolonging its lifespan and ensuring a resilient and long-lasting surface.

- Q:Are waterproofing membranes resistant to hail damage?

- Yes, waterproofing membranes are generally resistant to hail damage. They are designed to withstand various weather conditions, including hailstorms, without getting damaged or compromised.

- Q:Can a waterproofing membrane be applied to curved or irregular surfaces?

- Indeed, it is possible to apply a waterproofing membrane to surfaces that are curved or irregular. In the market, there exist flexible waterproofing membranes that have the ability to adapt to different shapes and contours. These membranes have been designed to be stretchable, allowing for manipulation in order to perfectly fit curved or irregular surfaces while still maintaining their excellent waterproofing properties. It is crucial to select a membrane that is explicitly designed for these types of applications and to adhere to correct installation techniques to guarantee a secure and watertight seal.

- Q:Can a waterproofing membrane be used on tunnels with water drainage systems?

- Yes, a waterproofing membrane can be used on tunnels with water drainage systems. The membrane acts as a barrier, preventing water from penetrating the tunnel structure and directing it towards the drainage system for proper disposal. This helps to ensure the integrity and longevity of the tunnel while effectively managing water flow.

- Q:Are waterproofing membranes resistant to sulfuric acid exposure?

- Yes, waterproofing membranes are generally resistant to sulfuric acid exposure. These membranes are designed to provide a barrier against water and other chemicals, including sulfuric acid. However, the level of resistance may vary depending on the specific type and quality of the membrane. It is advisable to consult with manufacturers or experts to ensure the membrane's compatibility with sulfuric acid exposure in specific applications.

- Q:Are waterproofing membranes resistant to thermal cycling?

- Yes, waterproofing membranes are generally resistant to thermal cycling. These membranes are designed to handle the expansion and contraction that occurs due to temperature fluctuations, making them ideal for protecting structures from water damage caused by thermal stress.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

EPDM Waterproofing Membrane Used in Roofing Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords