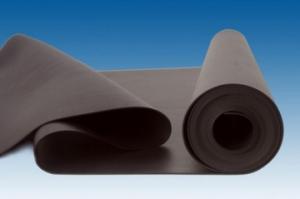

EPDM Rubber Waterproof Mmebrane for Basement Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Membrane

Product characteristics for EPDM Waterproof Membrane

1.Excellent anti-aging performance, service life can reach 50 years;

2.High elongation, high tensile strength, heat treatment size change small;

3.Plant root penetration resistance is good

4.Good low temperature flexibility

5.Application is convenient, overlapping is firm and reliable, no environmental pollution;

6. Resistance to chemical corrosion, can be applied to special places;

7.Maintenance is convenient, the cost is low

Uses for EPDM Waterproof Membrane

Widely used in roofs, basement, toilet ,swimming pool, and all kinds of industry and civil building waterproofing, reservoir, vivicism, bridge, underground, tunnel and dam waterproofing ,especially to the keystone waterproofing projects which is durability, high corrosion resistance and easy deformation

Specification for EPDM Waterproof Membrane

Item | Thick(mm) | Width | Length(m) | Color |

Spe | 1.0—2.0 | 1.2m/2m/3m/4m | 20 | Black |

Deviation | -1 +15 | --1 | Multicolor |

Technical Data for EPDM Waterproof Membrane

NO | Item | unit | Technical requirement | |||

1 | Tolerance on size | Thickness | % | ±10 | ||

Width | % | ±1 | ||||

length | % | Does not allow negative | ||||

2 | Fracture tensile strength (normal temperature ) | Mpa | ≥7.5 | |||

Fracture tensile strength(60 degree) | Mpa | ≥2.3 | ||||

3 | Breaking elongation,(normal temperature ) | % | ≥450 | |||

Breaking elongation,(zero 20 degree) | % | ≥200 | ||||

4 | Tearing resistance | KN/m | ≥25 | |||

5 | impermeability | * | 0.3Mpa impermeable | |||

6 | Bending at low temperature | °C | ≤-40 | |||

7 | Elongation and contraction volume at heating | Elongation | mm | ≤2 | ||

contraction | mm | ≤4 | ||||

8 | Hot air aging 80°CX168h | Fracture strength retention | % | ≥80 | ||

Rate of elongation at break | % | ≥80 | ||||

9 | Alkaline (saturated Ca(OH)2 solution normal | Fracture strength retention | % | ≥80 | ||

Temperature x2 168h ) | Rate of elongation at break | % | ≥80 | |||

10 | Ozone aging (40 degree by 168 hours ) | Elongation 40% , 500x10-2 | * | No Crack | ||

11 | Phytotron aging | Fracture strength retention | % | ≥80 | ||

Rate of elongation at break | % | ≥70 | ||||

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can waterproofing membranes be used on concrete tunnels?

- Yes, waterproofing membranes can be used on concrete tunnels. Waterproofing membranes are commonly used in construction to prevent water infiltration and protect structures, including concrete tunnels, from moisture damage. These membranes create a barrier that prevents water from seeping through the concrete and into the tunnel, ensuring its durability and longevity.

- Q: Are there any drawbacks or limitations to using a waterproofing membrane?

- Yes, there are some drawbacks and limitations to using a waterproofing membrane. One limitation is that it can be expensive to install, especially if it requires professional assistance. Additionally, if the membrane is not properly installed or maintained, it can become damaged or ineffective over time. Another drawback is that waterproofing membranes can limit the breathability of a structure, which can lead to moisture buildup and potential issues with mold or mildew. Finally, while a waterproofing membrane can protect against water intrusion, it may not fully address other potential sources of moisture, such as condensation or groundwater seepage.

- Q: Can a waterproofing membrane be used on breeze block surfaces?

- Using a different grammatical structure and expressions: Indeed, breeze block surfaces can benefit from the application of a waterproofing membrane. These concrete blocks, also known as breeze blocks, are commonly utilized in construction due to their porous nature. This porosity allows water to infiltrate the blocks, which can potentially lead to dampness or water-related harm within the building. To counteract this issue, the surface of the breeze blocks can be treated with a waterproofing membrane. A waterproofing membrane is a thin layer of material specifically designed to impede water penetration. It acts as a protective barrier, preventing water from seeping into the breeze blocks and safeguarding the underlying structure against moisture damage. This membrane is typically applied in either liquid or sheet form and securely adhered to the surface of the breeze blocks using an appropriate adhesive. Prior to applying the waterproofing membrane, it is crucial to adequately prepare the surface of the breeze blocks. This may involve thorough cleaning to ensure the absence of loose debris or contaminants. Additionally, any existing cracks or gaps in the breeze blocks should be addressed and repaired prior to the membrane application. This meticulous preparation is necessary to achieve a seamless and effective waterproofing system. It is important to note that the selection of the appropriate waterproofing membrane depends on the specific requirements of the project and the conditions to which the breeze block surface will be exposed. There are several types of waterproofing membranes available, such as liquid-applied membranes, sheet membranes, or cementitious coatings. To determine the most suitable membrane for your particular application, it is advisable to consult with a professional or the manufacturer. In conclusion, the utilization of a waterproofing membrane on breeze block surfaces is an effective means of preventing water penetration and safeguarding the underlying structure against moisture damage. Proper surface preparation and careful consideration of the appropriate membrane type are vital elements in achieving a successful waterproofing solution.

- Q: Can a waterproofing membrane be used for parking garage ramps and driveways?

- Yes, a waterproofing membrane can be used for parking garage ramps and driveways. These areas are often exposed to water, moisture, and other environmental elements that can cause damage to the structure over time. By applying a waterproofing membrane, it creates a barrier that prevents water penetration and protects the underlying concrete or asphalt from deterioration. This helps to extend the lifespan of the ramps and driveways, reduce maintenance costs, and enhance overall durability. Additionally, the use of a waterproofing membrane can also prevent water from seeping into the underground parking areas, preventing potential water damage and maintaining a safe and dry environment for vehicles and pedestrians.

- Q: Can a waterproofing membrane be used on precast brass surfaces?

- Indeed, precast brass surfaces can indeed benefit from the application of a waterproofing membrane. These membranes have been specifically engineered to create a safeguard against water infiltration and can be utilized on various surfaces, such as concrete, metal, and precast materials. In the case of precast brass surfaces, this membrane can play a crucial role in averting water penetration, which holds particular significance in areas that are frequently exposed to moisture, such as bathrooms, kitchens, or outdoor environments. By implementing a waterproofing membrane, the precast brass surface becomes effectively shielded against potential water damage, corrosion, and deterioration, thereby ensuring its durability and preserving its visual appeal.

- Q: Are waterproofing membranes resistant to mineral oils?

- Yes, waterproofing membranes are generally resistant to mineral oils.

- Q: Does a waterproofing membrane have any impact on the thermal performance of a structure?

- Yes, a waterproofing membrane can have an impact on the thermal performance of a structure. A waterproofing membrane is typically used in buildings to prevent water infiltration, which can cause damage to the structure over time. By creating a barrier against moisture, the membrane helps to maintain the integrity of the building envelope and protect against potential leaks or water damage. In terms of thermal performance, a waterproofing membrane can help to improve insulation by reducing the amount of heat transfer through the building envelope. By preventing moisture from entering the structure, the membrane also helps to prevent the formation of condensation, which can lead to mold growth and further damage to the building materials. Furthermore, some waterproofing membranes are designed with additional insulation properties, such as foam or reflective coatings, which can further enhance the thermal performance of a structure. These membranes help to reduce thermal bridging and improve energy efficiency by minimizing heat loss or gain through the building envelope. It is important to note that the impact of a waterproofing membrane on the thermal performance of a structure can vary depending on the specific type of membrane, its installation, and the overall design of the building. It is advisable to consult with a professional architect or engineer to determine the most suitable waterproofing solution that meets both the water resistance and thermal performance requirements for a particular structure.

- Q: What is the difference between construction non-vulcanized waterproofing membrane and vulcanized waterproofing membrane?

- Non-vulcanized rubber waterproofing membrane: from SR or SR and asphalt blends by mixing, rolling made of coil, without vulcanization can use the product. The bonding between the coils and their bonding properties with the mortar is good, the manufacturing is convenient, the price is low, but the tensile strength is low. Can be divided into two types of rubber and rubber asphalt. Rubber type commonly used SBR and other SR production. Generally used for civil construction roof waterproof.

- Q: Does a waterproofing membrane require a protective layer?

- Yes, a waterproofing membrane typically requires a protective layer. The protective layer serves multiple purposes. Firstly, it helps to prevent damage to the waterproofing membrane during and after installation. It acts as a barrier against sharp objects, construction debris, and potential punctures. Additionally, the protective layer helps to distribute loads evenly and provide stability to the membrane, reducing the risk of damage caused by foot traffic or heavy equipment. Furthermore, the protective layer serves as a UV barrier, shielding the waterproofing membrane from the harmful effects of sunlight exposure. UV rays can degrade the membrane over time, leading to reduced effectiveness and potential leaks. The protective layer also helps to regulate temperature fluctuations, which can expand and contract the membrane, causing stress and compromising its waterproofing capabilities. In summary, a protective layer is essential for the longevity and performance of a waterproofing membrane. It safeguards against physical damage, UV radiation, and temperature fluctuations, ensuring the membrane's effectiveness in keeping water out and preserving the integrity of the structure it protects.

- Q: Can a waterproofing membrane be used on stone surfaces?

- Yes, a waterproofing membrane can be used on stone surfaces. Stone surfaces, such as natural or manufactured stone, can benefit from the application of a waterproofing membrane to prevent water penetration and protect against moisture-related issues. Waterproofing membranes are designed to create a barrier against water and other liquids, preventing them from seeping into the stone and causing damage. This can be particularly important for exterior stone surfaces that are exposed to rain, snow, and other weather conditions. Additionally, using a waterproofing membrane on stone surfaces can help prolong the lifespan of the stone by reducing the risk of cracks, spalling, and other forms of deterioration caused by water absorption. It is essential to choose a waterproofing membrane specifically formulated for stone surfaces to ensure proper adhesion and long-lasting protection.

Send your message to us

EPDM Rubber Waterproof Mmebrane for Basement Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords