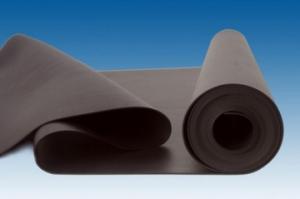

EPDM Rubber Waterproof Membrane for Roofing, Basement, Pond

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3600 m²

- Supply Capability:

- 250000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Vulcanized / Weldable EPDM Rubber Waterproof Membrane

EPDM rubber waterproof membrane for roof and basement

Width: 1.2m.2m.3m,4m

Length: 20m

Thickness: 1.2mm/1.5mm/2.0mm

Type: Vulcanized / Weldable

Profile of EPDM Waterproof Membrane:

EPDM waterproof membrane is made from ternary ethylene-propylene rubber,which is designed for waterproofing of exposed and non-exposed applications. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

CNBM own the wold-advanced equipment of cold feeding extrusion and continuous vulcanization technology. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or cracked under normal building movement.

Advantages of EPDM Waterproof Membrane:

-Excellent weather-ability, durability and size stability

-Good adaptability to high and low temperature, UV resistant and anti-corrosion

-High tensile strength and good elongation, accommodating to structure movement

-Easy installation, solid joint, and mo environmental pollution

-Good rooting penetration resistance

-Service life up to 50 years

Applications of EPDM Waterproof Membrane:

Widely used in roofs, basement, toilet ,swimming pool, and all kinds of industry and civil building

waterproofing, reservoir, vivicism, bridge, underground, tunnel and dam waterproofing ,especially

to the keystone waterproofing projects which is durability, high corrosion resistance and easy

deformation.

-Roof, basement, tunnel, pond liner, dam

-Industrial and civil building waterproofing

-Geosynthetic liner for fish ponds, swimming pools, channels, irrigation system

-Especially suitable for projects with high requirement in durability, anti-corrosion and deformation

Specifications of EPDM Waterproof Membrane:

-Width of roll: 1.2m, 2m, 4m

-Length of roll: 20m, 30m or customized

-Thickness of membrane: 1.2mm, 1.5mm, 2mm

-Type: vulcanized EPDM or welding EPDM

-Application: roof, basement, pond, lake, swimming pool, steel structure roofing, underground, tunnel, etc

FAQ:

1. Is your EPDM waterproof membrane the real rubber?

Yes, our EPDM membrane is made from top quality rubber, which is imported from America. We support samples for testing, or testing in our factory.

2. How's your products quality?

Our EPDM is with the top quality at home and abroad. Our quality is much higher than Chinese standard. Our product is widely used in Chinese Central government projects. And it's also accpted by customers all over the world, such as EU, USA, Astrulia, etc.

3. What's the service life of your EPDM membrane?

The service life of our EPDM membrane is more than 50 years.

4.What's your MOQ?

Our MOQ is 3000M2.

5. What's your product ability of EPDM membrane?

We own the largest EPDM production line in China. Our product ability of EPDM membrane reaches 2 million square meter per year.

Photos of EPDM Waterproof Membrane:

- Q: Can a waterproofing membrane be used in conjunction with tile or stone installations?

- Yes, a waterproofing membrane can be used in conjunction with tile or stone installations.

- Q: SBS waterproofing membrane how to sample

- SBS modified asphalt waterproofing membrane, APP modified asphalt waterproofing membrane: the same manufacturers, the specifications are not more than 10000m2 for a number of qualified qualified coil, each batch of random 1

- Q: Can a waterproofing membrane be applied over existing coatings or sealants?

- Indeed, existing coatings or sealants can be overlaid with a waterproofing membrane. Nevertheless, it is crucial to adequately prepare the surface and eliminate any flaky or impaired coatings or sealants prior to applying the waterproofing membrane. This will guarantee optimal adhesion and efficiency of the membrane. Furthermore, it is advisable to refer to the manufacturer's instructions or acquire expert guidance to guarantee compatibility between the existing coatings or sealants and the waterproofing membrane.

- Q: What is a waterproofing membrane?

- To prevent the passage of water or moisture, one can apply a thin layer or sheet of material known as a waterproofing membrane onto a surface. This technique is widely utilized in construction, especially in areas where water infiltration is a concern, like roofs, basements, and bathrooms. By acting as a barrier, the membrane effectively stops water from seeping through and causing harm to the underlying structure. Enhancing its effectiveness, multiple layers of the membrane are typically applied, which can be composed of various materials such as rubber, bitumen, or synthetic polymers. In order to endure environmental factors like UV radiation and temperature fluctuations, these waterproofing membranes are meticulously designed to be flexible, durable, and resistant. By keeping buildings dry and safeguarding them from water-related problems such as leaks, mold, and deterioration, they play a crucial role in ensuring the longevity and integrity of structures.

- Q: Can a waterproofing membrane be used for underground parking garages?

- Underground parking garages greatly benefit from the utilization of a waterproofing membrane. To safeguard against water infiltration and consequent harm, it is highly advised to employ such a membrane in these specific structures. Surrounding soil often poses a threat of water seepage in underground parking garages, leading to structural decline, corrosion of steel reinforcements, and the proliferation of mold and mildew due to constant exposure to moisture. A waterproofing membrane acts as a protective barrier, effectively preventing water from permeating the walls and floors of the garage. It is carefully applied to the exterior surfaces of the structure, forming a shield that ensures the interior remains dry and devoid of water-related issues. The selection of the appropriate membrane should be based on project-specific requirements, taking into account factors such as construction materials, groundwater conditions, and expected water pressure levels. Furthermore, proper installation techniques and regular maintenance are paramount to ensure the long-term efficacy of the waterproofing system.

- Q: How does a waterproofing membrane handle settlement or movement of the substrate?

- A waterproofing membrane is specifically designed to handle settlement or movement of the substrate. It achieves this by offering flexibility and elasticity. Typically, it is made from materials such as modified bitumen, polyurethane, or acrylic polymers. These materials possess the ability to stretch and contract without compromising the membrane's integrity. In the event of settlement or movement in the substrate, the waterproofing membrane adjusts its shape and size accordingly. This prevents the occurrence of cracking or tearing in the membrane, which could result in water infiltration and damage to the underlying structure. Some waterproofing membranes go even further by including reinforcing layers or fabrics embedded within them. These layers enhance the membrane's strength and resistance to movement. They also help distribute stress and forces caused by settlement or movement, providing further protection against potential damage. In addition, proper installation techniques are of utmost importance to ensure the waterproofing membrane can effectively handle settlement or movement. The membrane should be applied in a continuous and seamless manner, using appropriate adhesives or fasteners to secure it to the substrate. This ensures that the membrane can flex and move in sync with the substrate, rather than resisting or restricting its movements. To sum up, a waterproofing membrane is created to accommodate settlement or movement in the substrate. It achieves this through flexibility, elasticity, and reinforcement. Proper installation techniques are crucial to ensure its effectiveness in handling these movements and maintaining a watertight barrier.

- Q: What is the difference between pressure-sensitive self-adhesive waterproofing membrane and sbs asphalt waterproofing membrane?

- 3, from the price ? Pressure-sensitive self-adhesive waterproof membrane price is more affordable, quality assurance, as if there is a good product of home, such as macro cattle Xugong, the price is more affordable, quality assurance. And sbs asphalt waterproofing membrane is more expensive.

- Q: Can a waterproofing membrane be used in conjunction with green building practices?

- Yes, a waterproofing membrane can definitely be used in conjunction with green building practices. In fact, incorporating a waterproofing membrane into the construction of a green building can help enhance its overall sustainability and efficiency. One of the key principles of green building practices is to maximize energy efficiency and reduce the environmental impact of a building. By installing a waterproofing membrane, the building's envelope can be protected from moisture intrusion, preventing water damage and potential mold growth. This, in turn, helps maintain the structural integrity of the building, reducing the need for repairs and replacements, which can be resource-intensive and generate waste. Additionally, a waterproofing membrane can contribute to better indoor air quality. By preventing water infiltration, it helps create a dry and healthy living or working environment, minimizing the risk of respiratory issues and other health problems associated with dampness. Furthermore, a waterproofing membrane can improve the energy efficiency of a building. By preventing water from seeping into the walls or foundation, it reduces the potential for heat loss through moisture evaporation, thus reducing the energy needed for heating and cooling. This can lead to reduced energy consumption and lower carbon emissions, aligning with the goals of green building practices. It is important, however, to choose a waterproofing membrane that is environmentally friendly and meets green building standards. Look for membranes that are made from recycled or sustainable materials and have low VOC (volatile organic compound) content. Additionally, consider selecting a membrane that is designed for durability and longevity, as this can further reduce the environmental impact by minimizing the need for replacement over time. In conclusion, a waterproofing membrane can be a valuable addition to any green building project. It helps protect the building envelope, improves indoor air quality, and enhances energy efficiency. By selecting an environmentally friendly membrane, the overall sustainability of the building can be further improved.

- Q: What is the PEDM waterproofing membrane material?

- Process: clean up the grassroots → brushing the primary treatment agent → additional layer of treatment → film paste surface coating → base surface coating → coil bonding, exhaust, compaction → coil joint bonding, compaction → roll Material end of the head and edge processing → do protection.

- Q: Can a waterproofing membrane be used for water tanks?

- Yes, a waterproofing membrane can be used for water tanks. Waterproofing membranes are specifically designed to prevent the passage of water and can effectively seal water tanks, ensuring that they remain watertight. These membranes are commonly made from materials such as bitumen, PVC, or EPDM, which provide excellent resistance to water and are capable of withstanding the harsh conditions often found in water tanks. Additionally, waterproofing membranes can be applied to various surfaces, including concrete, metal, and masonry, making them versatile and suitable for different types of water tanks. Overall, using a waterproofing membrane is a reliable solution for ensuring the integrity and longevity of water tanks by preventing water leakage and protecting the surrounding environment from potential water damage.

Send your message to us

EPDM Rubber Waterproof Membrane for Roofing, Basement, Pond

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3600 m²

- Supply Capability:

- 250000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords