End Suction Centrifugal Horizontl Water Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

End Suction Centrifugal Pump

1.Structure of End Suction Centrifugal Pump Description

End Suction Centrifugal Pump complies fully to the European Standard BS EN733 / DIN24255 of performance and dimensions. They are used for pumping clean water or liquids similar to water, achieving wide application on plants, mines, city water supplies, air-conditioning coolers, firefighting system and irrigation. Pumps of the same model have different performance levels basing on different diameter after impeller trimming. Overall the whole series, there are only four sizes of shaft and five of bearing housing. As long as their bearing housings are of the same size, different pumps can interchange chief parts such as shaft, shaft sleeve, shaft seal, impeller nut, etc.

End Suction Centrifugal Pump is also very easy to be installed and maintained. Back pull-out design, driven through flexible coupling, so that pump casing and motor can remain in position while other spare parts are removed.

2.Main Features of the End Suction Water Pump

• very easy to be installed and maintained

•Back pull-out design

•Driven through flexible coupling

•Customized design is available, OEM and ODM are welcomed.

•Horizontally and vertically installation as different pipeline system

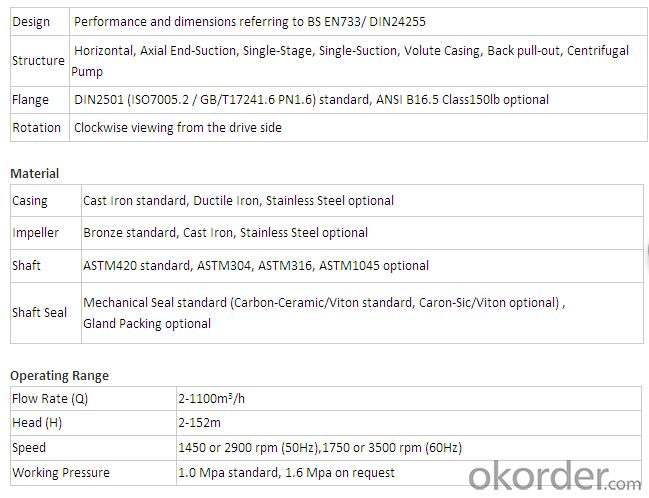

3.End Suction Water Pump Specification

4.Picture of End Suction Pump

5.FAQ

① What is your product range?

Centrifugal pump, slurry pump, gravel pump, clean water pump, sewage pump, chemical pump, single stage

pump, double suction pump, industry pump, oil pump, paper pulp pump, mud pump, self-priming pump, pipe

water pump, boiler water pump, etc.

② Are you a manufacturer?

Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years.

③ What information should I let you know if I want to get a quotation?

Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also provide the pump model you are using now, price will be calculated as per the pump model, if not, we will recommend relevant product for reference.

- Q: what water pump is on a 1978 mercruiser 170hp 224cc 3.7 liter

- Something in your description doesn't add up. Mercruiser did not have a motor branded as 170 hp in 1978, only 85-86. The 224s where a Mercury invention, all about the same for around 15 years. Do you you have a ser #, much more accurate identification.

- Q: 1998 Honda civic water pump plastic or metal inside (OEM)?

- nearly all honda water pumps are all metal construction...including this one.

- Q: please answer my below question whether it is possible or not.can i get 15,00,000 lit/day amount of water by using 10hp water pump at the distance of 5m total head?

- This Site Might Help You. RE: what is the discharge amount of 10hp water pump? please answer my below question whether it is possible or not. can i get 15,00,000 lit/day amount of water by using 10hp water pump at the distance of 5m total head?

- Q: How long would it take before I would see water coming out of the exhaust bellow? I let it run for about 5 seconds or so and shut it of fearing it would burn up. Did this a few times and finally gave up. Pump wasn't hot and impeller was still good. Wondering if I just didn't let it run long enough?

- i've always gone by the 30 second rule. even a NEW or emptied for winter motor that must completely fill, 30 seconds should be long enough. if it hasnt begun pumping by that point, i turn it off and give it some time to cool while i double check everything. then i might give it a full 45 seconds. but it wont overheat in less then a couple of minutes. and if its not pumping with the hose hooked up, the impeller is probably bad already anyways. however, if you do even get it near warm, its already hotter then you think it is where the heat is produced, the cylinders, and where you have tight clearances on fast moving parts, the cylinders and pistons. and if it gets too hot, major damage is quickly done. BTW, service period on a merc impeller is always 100 hours or 3 years. or NOW, before the motor is damaged, if unsure of when it was last done. when the impeller is less then $50 (and about an hour labor, if paying for it) and a new motor is THOUSANDS, you cant replace it too often. dennis, you have NO clue. i suggest getting one before you ruin the motor in your own boat. and in the meantime, keep your bad advice to yourself.

- Q: i want to make this for a physics project for school. i found a video on how to make it, but i dont understand the physics behind. i have to make a model and a poster explaining the physics. i dont understand what to put on the poster so could someone help me with which physics principles this project would go with?

- It isn't practical to give a detailed description here. This is a positive displacement pump. The pump chamber is sealed so that as the piston is moved up the volume within the chamber increases. Water is pushed into this chamber by the outside air pressure. If the pump is located too far above the water source then the air pressure is not sufficient and you will produce a vacuum inside but the water still will not flow. When the pump is pushed down the water flows out. Now the one way valves are critical. We don't want the water to flow back the way it came and we don't want the water that we have already pumped to flow back into the pump. So a one way valve on the inlet will permit water to flow into the pump but not out of it. And a one way valve on the outlet will permit water to flow OUT of the pump but not into it. So with each stroke you a) reduce the pressure in the pump. b) water is forced from the inlet, past its one way valve and then into the pump. c) the pump is pushed down increasing the pressure in the pump. d) water flows out of the pump through the other one way valve and on to the output.

- Q: as i asked before in my question what needs to be fixed when a water pump goes bad. so finally it went bad today the car leaked all coolant and for some reason all the blades on the fan broke and the battery light came on. which is connected to the alternator belt so thats not the problem. so now does anybody have any idea how much it would cost to fix and by what i know it needs a new belt for water pump and new fan and water pump etc. taking it to mechanic monday but wanna get an estimate first from u people. any ideass thanks

- Oh you found one doe 60 bucks good for you. Lot cheaper than the dealer quoted you. When a water pump job is done the fan and belt are removed anyways. So all you will have to buy is the new fan, the belt if you want. The other parts you listed are probably fine. The tech will inspect them when doing the water pump (if he's on top of things) and he'll let you know.

- Q: i heard a water pump should not be able to move.is that correct? It is a 1995 RM250. there is no clogging in the pipes coming from the radiators with 2 fingers require force to move them but with the 1 finger it requires no force to move a couple Centimeters.

- The water pump is turned by the primary gear on the crankshaft. When you were turning the water pump - the crankshaft was moving the piston up down in the cylinder. The couple of centimeters of movement is just the play between the gears - that's normal.

- Q: It is used in a water pumping station.

- This Site Might Help You. RE: What is a submersible pump and how does it work? It is used in a water pumping station.

- Q: the pump inlet how hard is this to replace i know the timing chain cover has to be removed and is this the propable place of the leak

- If okorder has printable online manuals for most repairs but if you aren't mechanically inclined and have little experience I would advise you to take it to a mechanic and have it fixed properly. Depending on the vehicle most water pump replacement cost between 2 and 3 hundred at a garage. The timing chain cover never needs to be removed to change a water pump.

- Q: the car over heats and I hear the antifreeze boiling and it also leaks a small amount of antifreeze amechanic told me i need a thermostat and a new water pump just looking for second opinion.

- First check the water pump for leaks and wiggle the shaft to check for bearing wear. If either is present replace the pump along with the thermostat. If not only replace the thermostat. If the radiator is boiling over after a short drive, the thermostat needs replacing.

Send your message to us

End Suction Centrifugal Horizontl Water Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords