Dry Profile-for Partition System in Decoration

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Profile for Ceiling and Partition System

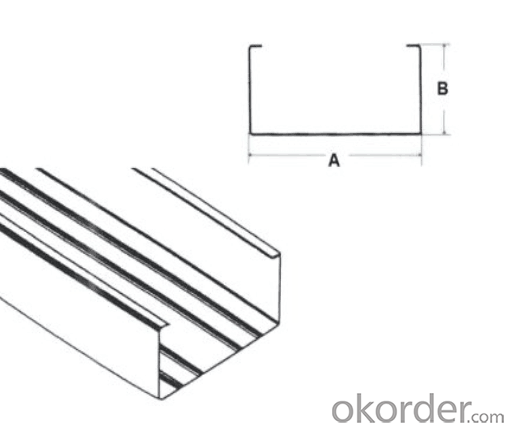

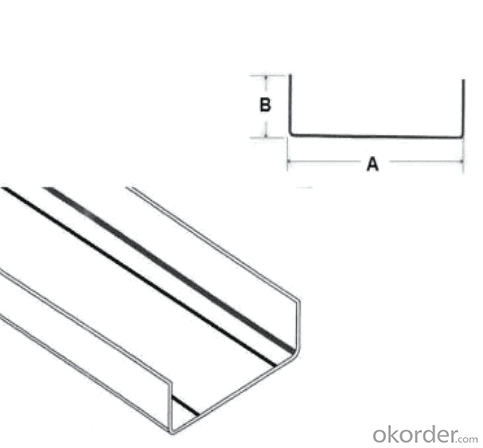

Drywall steel profiles are widely used in buildings for ceiling & partition systems with different kinds of boards, such as gypsum board, calcium silicate board, magnesium oxied board, fiber cement board... Drywall steel profiles are made of galvanized steel, and can be installed easilly. Besides, thermal and acoustic insulation products maybe filled in partition system to provide a safe and fire-resistant wall, and create a quiet environment.

Specification of Drywall Steel Profile:

Size: Different series of sizes for different markets

Thickness: 0.40~1mm

Length: normal 3m/piece

Zinc-coating: normal 50~60g/m2, or to order

Packing of Drywall Steel Profile:

Pcs into a bale (normally pack by tapes), bales into containers / wagon

Delivery of Drywall Steel Profile:

From Xingang (port) or Tianjin (station), 3 weeks in receipt of advance payment

Installation of Partition with Drywall Profiles and Accessories:

1. Marking

2. Fix the stud and track

3. Install the steel channel

4. Install the boards

5. Jointer application (accessories, screw, jointer, tape, insulation material)

- Q:100 square light steel keel wall how many pieces of heaven and earth keel

- Heaven and earth keel accurately depends on the length of the wall, the dragon than the dragon multi-hole size. Usually can be doubled the length of the wall to remove the door. Vertical spacing is usually 400, the door has to strengthen the vertical keel, wearing a keel to see the height of the wall, you can 1, but also two. Depending on the specific design. If the height of 3m, heaven and earth keel to 67m-several door size.

- Q:Decorative light steel keel paper gypsum board wall height of 4.1 meters span 6.5 meters need not add structural column, beam

- Light steel keel gypsum board wall with a certain distance set by the vertical galvanized main keel, which is made of thin steel plate C-shaped or I-shaped cross-section of the rigid components, the upper and lower ends should have connectors and structures firmly Fixed, do not need to pour concrete construction column. 4.1 meters high has not seen the practice of pouring concrete belt.

- Q:Light steel keel gypsum board partition wall construction practices and construction process What is the difference?

- And traditional wooden keel wall for comparison? Basically, the framework is different, flatness is different, the cost is different.

- Q:Wood keel can be used to ceiling, can be used to do the wall? Light steel keel can be used in what place?

- Many temporary buildings will use wood keel to do with the wall, light steel keel more for long-term construction

- Q:Light steel keel partition wall door how to do

- The wall keel to use the national standard light steel wall keel - the thickness of the strength of only;

- Q:Light steel keel wall waterproof

- 1. The use of steel coated excellent 1011 metal roof for high-elastic waterproof coating (grass-roots) Used for bonding with the substrate, to achieve 100% continuous sticky. 2. Use 1032 to enhance the polyester cloth Used to enhance the coating of tensile, tear resistance and fatigue resistance. 3. The use of steel coated excellent 1011 metal roof for high-elastic waterproof coating (grass-roots) By enhancing the gap of the mesh structure of the polyester cloth, the intermediate layer and the base coating are fully infiltrated and integrated to effectively enhance the sealing performance of the coating. 4. Use steel coated excellent 1021 metal roof dedicated high-elastic waterproof coating (surface)

- Q:Light steel keel wall circuit how to wear pipe

- 1, to C-type vertical keel on the threading hole as the basis, first determine the direction of the upper and lower ends of the keel, try to align the threading hole. Vertical keel length size, should be measured according to the size of the scene. The premise is to ensure that the vertical keel can be along the ground, along the long keel slot slide. 2, light steel wall vertical keel installation spacing, according to the actual width of the panel size and wall structure design may be. 3, vertical keel installed in place, should ensure that the vertical. Door and window openings should be taken double row of vertical keel reinforcement. When the design requirements for the steel connection, the vertical keel and the edge along the top keel of the fixed, the application of self-tapping screws or shaft rivets to connect. sixth,

- Q:Light steel keel with what screws fixed gypsum board

- That is, depending on the general distance from the general self-tapping screw teeth to be larger. Fast teeth screws are generally used for wood, aluminum and other materials, in the role of power tools, you can quickly into the material inside their own. Because the fast tooth screws are mostly self-attack class, will not use the nut. Ordinary screw general mechanical screws, can support the nut. ??? Mechanical screws and self-tapping screws are very different in tooth pitch.

- Q:The walls are light steel keel gypsum board partition, the property requirements can not move, but I would like to do a word on the wall shelf, how construction?

- Can only use the exhibition frame. You may be a mall. Now shopping malls are so, independent to be a exhibition,

- Q:House decoration, the designer said the wall with light steel keel good, but the construction told me that this low efficiency can only be maintained for 4,5 years so I do not know in the end listen to who

- With light brick wall, there are 1.5 and 1.2 the price is about 60 it

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Dry Profile-for Partition System in Decoration

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 40000 pc/month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords