CUMMINS generator with soundpfoof from Shanghai Ruiying 100kva

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Low-noise 100kva Cummins Diesel Generator 50/60hz

Briefe performance of silent diesel generator set

1)High quality, steady and reliable performance

2)Blow 71dB at 7 meter

3) Perfect Maneuverability

4) Wide Application

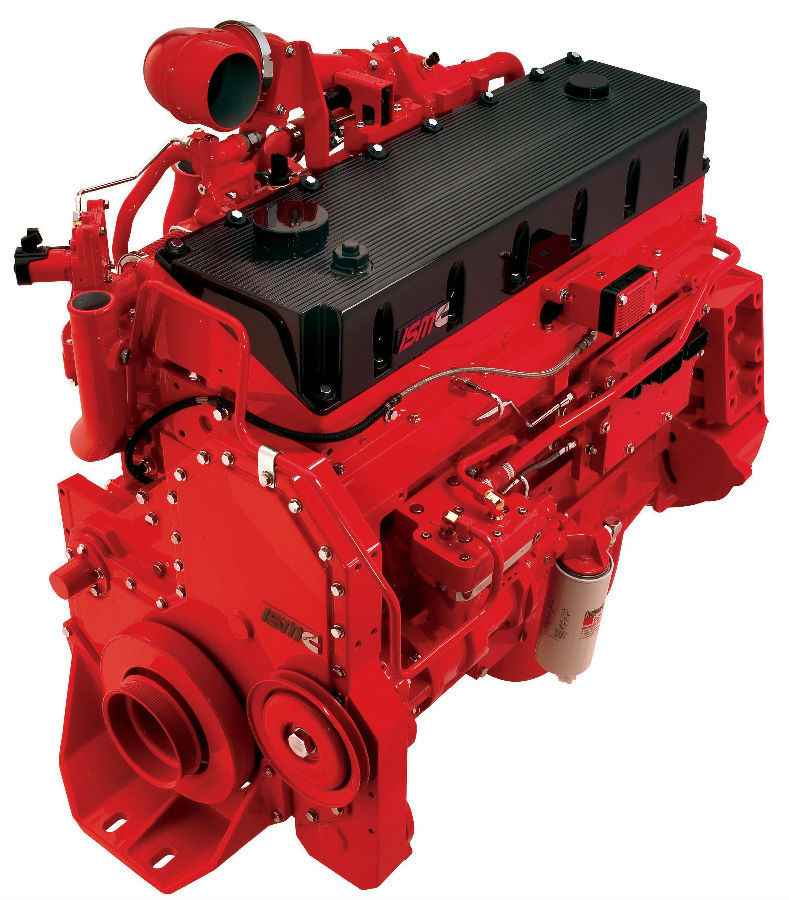

Cummins Engine

Alternator

Engine | CUMMINS 6BTA5.9-G2 |

Alternator | STAMFORD UCI274C |

Control system | SMARTGEN HGM6120KC |

Accessory | Fuel tank 600L Breaker TIANZHENG Start battery 100Ah×2 |

Manufacturer | CUMMINS | |

Model | 6BTA5.9-G2 | |

Cylinder and cycle type | 6 cylinders in line, 4 strokes | |

Aspiration and cooling | Turbocharged and after cooled | |

Displacement | 5.9 L | |

Bore×Stroke | 102×120 mm | |

Compression ratio | 17.5:1 | |

Rated speed | 1500 rpm | |

Governor | Electronic | |

Oil capacity | 16.4 L | |

Prime power | 90kW | |

Standby power | 99kW | |

Fuel consumption | 22L/H (100% Load) | 17L/H (75% Load) |

Coolant capacity | 9.1 L | |

Start system | DC 24V | |

Alternator Specifications:

Alternator Specifications:

Manufacturer | STAMFORD |

Model | UCI274C |

Type | Single bearing,4-pole,AC brushless and self-exciting |

Frequency | 50 Hz |

Power Factor | cosΦ=0.8 |

Phase | 3 |

Voltage | 400/230 V |

Capacity | 80kW/100kVA |

Insulation class | H |

Protection class | IP23 |

Elevation | ≤1000m |

Control System(DSE from UK)

HGM6120KC Control System is mainly used in generating supervising and control of land type diesel generator set and the switching between diesel generator set and city electricity supply. It is combined with digitalization, intelligence and network and capable of generator start and stop, generator data supervising and testing, protection alarm, city electricity supply quality supervising and starting generator automatically when power failure happens or city electricity supply is beside the set point.

Silent/Low noise generator

Light Tower with Trailer Generator Set

Trailer and low-noise generator

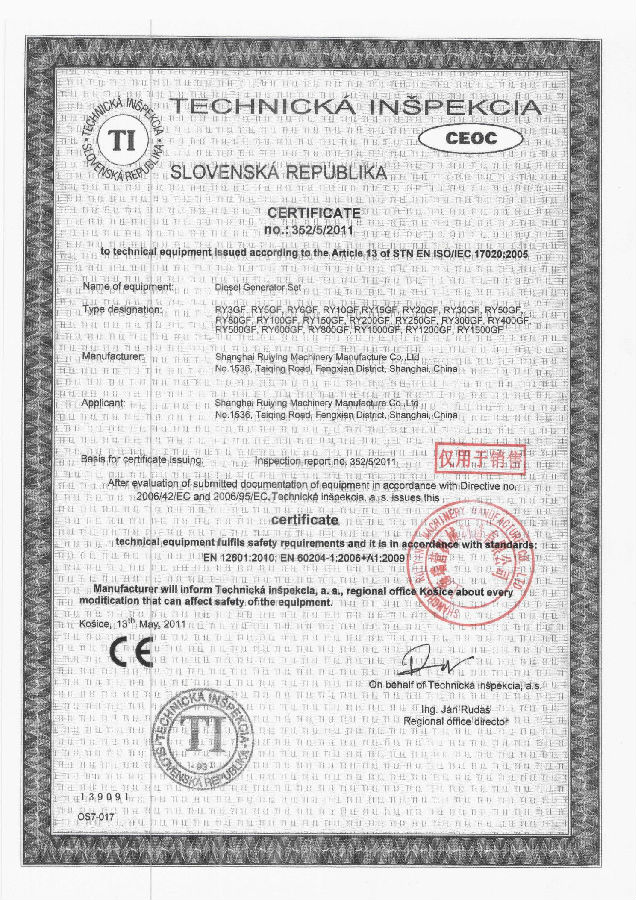

Certifications

Our Factory

- Q: As soon as I turn off the heat, the whistling sound dissapears

- Yes the motor could be locking up, it could also be some debris in the motor fan. Leaves or pine needles, etc. FOURFROMMOORE

- Q: The other night my ac was making a noise like something was in there, we checked and surprisingly there was a dead snake in my car's ac motor. We took it out, found out how it got in there and fixed that problem... but since we found the snake, a rancid smell has been in my car,(especially when the ac is on). I tried putting baking soda and air freshener in my car but the smell isn't going away... any ideas on how to get rid of the odor?

- what's so undesirable approximately it? i could no longer count quantity the circumstances that i've got scared my mom to loss of life from putting a lifeless snake on authentic of her motor vehicle, on the door guard, or on the front steps. that's in all threat basically a prank. do no longer trouble approximately it.

- Q: What is the difference between Tesla's Alternating-Current Electric Motor and an induction electric motor? Thanks for your answer.

- bypass to a broking and ask them for suggestions on the fashions. i'm specific they may be prepared to try this and answer questions you have. Their enterprise is merchandising automobiles and you're a ability customer.

- Q: What is the influence on the motor when AC motor is connected to direct current?.

- First of all, the motor will not turn, and the second is to see how many volts you are connected to. If the voltage is high, the temperature of the motor will rise sharply until burned. Of course, you don't have a problem with a dry battery.

- Q: Is it possible to increase an HP of motor by doing some changes in winding ?

- It is possible to increase the motor horsepower rating but only when the motor winding wire size is increased during a rewinding. But, the rewinder has to check if the the new wire size and same number of turns will fit in the slots.A good insulating paper has to be used.

- Q: I'm working on a sculpture piece, I need a way to turn a large 40quot;, 100 pound wheel at about 1 revolution per hour.I'm wondering what kind of motor I could use for this?So far I've come up with either a windshield wiper motor, an auger motor, or a microwave's turntable motor. I would have to gear them down further than they already are to get my wheel spinning at 1 rph...But would these motors burn out after a few days time running non-stop? Is there a better alternative out there?I was also thinking some sort of time-based controlled motor, maybe Arduino based?

- You need an industrial quality motor and gear arrangement. There are electric motors in industry that run 24/7 for as much as a year with no problem. I can't quote you the exact industry standard but any company that sells motors will know what you need.

- Q: Is it an universal motor which works on ac or dc voltage,how does it work,speed regulation rheostat foot pedal,I mean can someone explain me technically how a sewing machine motor works,and how to connect it back after rewinding,thank you.

- dear sir, how can we check is it univeral (ac, dc ) motor, please explain. thanking you

- Q: Just need to know what most blenders use Thanks

- Most blenders have brush-type motors that look like they could run on DC, but they can't; they run on AC only. Check the ratings on the bottom of the housing of any given blender to find out for certain. I would normally expect to see the words AC only there.

- Q: building a 30hp rotary phase conveter for my shop, need to know how many micro farids for this motor to start.

- The starting cap is sized to provide a phase shift to the start winding. Capacitance and voltage will depend on motor design, voltage, frequency, required starting torque, HP, and the design current of the start winding. You'll need to know alot more about your motor before doing the calculations. Your motor manufacturer has already done the work. Look 'em up. Don

- Q: I'm writing a persuasive essay for school and I need to know how the electric motor by Michael Faraday changed the world during the Industrial Revolution, yet still has a great impact on today's world. I know that without it transportation wouldn't be the same, but what are some other reasons it was/is so useful? (convenience, safety, etc.) Thanks!! :)

- You are using the term electric motor too loosely because there is the DC type and AC. Also Faraday's motor was a proof of concept, and was not a practical design to use. The modern DC motor with a commutator got its design ideas from Thomas Davenport's motor. The modern AC induction motor is the design of Tesla. The electric motors of both AC and DC changed the world by replacing the combustion engine in manufacturing applications with proven reliability and ease of speed and torque control (DC motors initially, since speed and torque control of AC motors was hard to figure out back then). Electric motors (mostly AC induction) are used in applications such as plastic injection molding machines, milling and lathe machines, compressors, forge presses, pumps, cranes, locomotives, conveyor belts, oil well pump jacks, hammer mills, ball mills, sawmills, printing presses, HVAC systems, etc. Basically, your average Joe would not know that electric motors greatly outnumber combustion engines and that electric motors are what make the majority of the products we buy. I hope you write a good essay so you can educate people that the combustion engine is the underdog, not the electric motor which has more market share. :)

Send your message to us

CUMMINS generator with soundpfoof from Shanghai Ruiying 100kva

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords