Cleaning In Place Machine for Stainless Tanks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

Processing: Washer, cutting-rolling -welding -polishing -assembing -testing -warehousing

Condition: New

Place of Origin: Zhejiang, China (Mainland)

Brand Name: KUNBO

Model Number: CIP cleaning machine, KB-009

Voltage: 380V, 50HZ

Certification: B&V, CE

Warranty: one year

After-sales Service Provided: Engineers available to service machinery overseas

Packaging & Delivery

| Packaging Details: | export standard package |

|---|---|

| Delivery Detail: | 25 - 45 days after deposit received |

Images:

Specifications

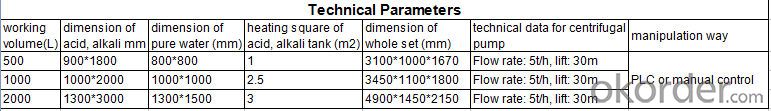

1.acid storage tank 2.alkali storage tank 3.fresh water storage tank

4.centrifugal pump 5.pipes and valves

| CIP Cleaner | |

| Company introducation | We Kuangbo is a production enterprise of pharmaceutical, dairy, food and beer-making equipment, alongside biological engineering, chemical containers, and bespoke products. Our products are widely used in beer production, pharmaceuticals, beverage industries, biotechnology and other fields. |

| Usage | it is used for cleaning pipes and tanks after the production process |

| Material | 1.SUS304, 316L |

| 2.as to the thickness, we can make it according to your requirement. | |

| Configuration | 1.acid storage tank |

| 2.alkali storage tank | |

| 3.fresh water storage tank | |

| 4.centrifugal pump | |

| 5.pipes and valves | |

| Our advantage | 1.we can supply various kinds of volume, minimum 50L, maximun 2,000L. |

| 3.interior surface is 3A finish and exterior is 2B finish | |

| 4.competitive price and also higher quality tank. | |

| Minimum order | one unit |

| Payment term | T/T or L/C |

| Package | export standard package |

| Market | at home and abroard |

- Q:how can you make a double boiler without a double boiler?

- Look for two pots about the same size, the one on the bottom holding the water should be slightly bigger but not by much, as the purpose for double boiler is to allow enough heat in the bottom pan to create a boil. You could do this stove top or use the oven with two oven safe pans, simply place one on top of the other.

- Q:What is the problem with the boiler? The fire is burning great but the water temperature isn't going past 70°. Problem just had started day before yesterday. Any advice is welcome

- The boiler is turning off too early. Have you sat with it until it did turn off and then measure the temperature? The setting might have changed, but who changed it is another thing to puzzle out. OR You have a water leak somewhere taking water out fast enough that the temperature never gets over 70 degrees.

- Q:had to wait 2 wks for new bladder. We asked if the radiators should be flushed but the engineer said you don't flush or put inhibitor in these. The engineer fixed it but still it wasn't quite right. He came back and said we needed a new pressure relief valve. Five minutes after he left we had to call him back as the boiler cut out, this happed 3 times more! We asked if we could get a manual for the boiler but he said that manuals are not given anymore because corgi doesn't want owners to try and fix them.Still it wasn't right. He came back and said we needed a new radiator in the boiler, he came back an The hot water is only on for about 4 seconds then it goes cold. This has been going on since november. Now my husband has put cleaner in the rads and is going to try and fix it, mentioning something about a 3 way valve. It seems to me that yes we needed a new bladder but I think we just needed the system cleaned in the first place.Anyone got any helpful advice please?

- By bladder do you mean hot water diaphragm. It is not true that Corgi do not want boiler manuals given out. It is part of the regulations that a boiler manual is left with the boiler on installation. You might be able to get hold of a copy from Halstead or whoever owns them now or download a copy off the internet. However what is true is that you shouldn't be repairing them yourself. I have a feeling that these boilers can go to lock-out because the venturi is dirty and also for lots of other reasons as well so don't waste your money havoing a go at different cures. To diagnose blocked heat exchanger you could put temperature sensors on flow and return. To diagnose venturi problem another method is used. You need an experienced combi boiler engineer really not Joe cowboy.

- Q:I was wondering also in the case of two boilers on the same steam header, and feed by seperate return pumps from a common return tank. When turning off and valve down one of the two at the header main gate valve. Would the vacumn that is made draw and raise the level in the boiler that is cooling down? Is it neccessary to turn off the down return pump and valve off the return line. I would think...the negitive pressure would pull in return past its return line check and hold excess water. Help!!

- I would say, put one boiler on fixed load (flow rate) and the other on variable load (flow reset by pressure) so the header pressure is maintained. That is the basic principle for load sharing.

- Q:What units are boilers?

- The use of boilers is very wide, the species also mix, vary widely:

- Q:Summary of safety knowledge

- For the safety of public safety, people's lives and property, according to the State Council "special equipment safety supervision regulations", the use of boilers should note the following:

- Q:This seems a bit tight to me! We are about to sign a tenancy agreement for a new house and in it it states that the tenant is responsible for organising and paying for the boiler to get serviced each year.I have checked with the letting agent and they have said that this is correct and that the 'all of the landlord's properties requires this.I'm quite miffed as I always thought that it should be the landlord's responsibility seeing as it's his house and his boiler. Thing is, everything is ready to go ahead - we have handed in notice at current place and move in in 2 weeks time so we are going to have to sign this tenancy. Just seems a bit rubbish to me :(

- The letting agent must surely be having a laugh with you. Remind them that a landlord must have the boiler (and any other gas appliances) serviced on an annual basis. They must also provide a tenant with a landlords' gas safety certificate. Your landlord has these duties by law. It doesn’t matter if your tenancy agreement or the agreements of your landlord's other tenants says that they are a tenant's responsibility – they aren’t. You might also like to remind them that the Property Ombudsman (www.tpos .uk/) would be quite interested to hear about them peddling unlawful clauses in their contracts. I understand that at this stage you've probably invested too much time and money to simply walk away from the house, although this is honestly what I'd advise doing: a landlord who's playing silly games before the tenancy even begins doesn't bode well for the duration of the tenancy. You would be able to claim back any fees you've paid to the agent through the small claim's court on the basis that they are knowingly giving you false information. If you do go ahead with the let, hopefully when you make it clear to the agent that you're not a mug and want this particular clause removed from the tenancy agreement, they'll do so without argument. For future reference, the Health and Safety Executive (HSE) is responsible for enforcing gas safety. If your landlord doesn't provide you with a gas safety certificate or further tries to insist that you need to have the boiler serviced yourself, you can call the HSE helpline on 0845 345 0055 or 0800 300 363 or contact your nearest office - details are available on the HSE website.

- Q:what is the difference between ASME S stamp and BS 12952?

- one big cert is Boiler Welding. Boiler steel is much thicker than other steels and also is different in composition.

- Q:I am running new wiring in my home and was wondering if my natural gas boiler and natural gas hot water heater need to be on separate circuits? Also should I put each bedroom on its own circuit? How many outlets should go on each circuit?

- Dan h is correct but if it's electronic ignition the power consumption required is minimal [ very little is needed]therefore it would be OK to put on boiler circuit..........................as for the bedrooms i personally put on separate circuits ......... to save money i would run 12/3 w/grd then you would have 2 circuits in one wire .....you can share one nuetral for 2 circuits its allowed by the CODE......... as for the plugs ....you can use as many as you want ....... i wouldn't put more than 6 recepticals per circuit including bed lights is OK

- Q:can i use spray paint near my gas boiler if i turn it off first?

- DO NOT USE ANY THING NEAR YOUR GAS BOILER THAT HAS ANY KIND OF FUMES. My husband was inflating a wheelbarrow tire in the basement, and was close to our gas furnace, which has a pilot light. The furnace was not running, but when the fumes from the can of tire inflator reached the pilot light, it ignited and he was encircled in flames for a second till the fumes were burned off. Luckily, he was not burned, but the wheelbarrow tire continued to burn and he had to carry it outside while it was burning. If you use a can of spray paint and that happens it may explode in your hand, or you could be burned by the fumes igniting like what happened to my husband. Another thing that could happen is a build up of fumes if the boiler is in an enclosed area and that could ignite and cause an explosion. (Sorry for the capital letters, but I wanted you to notice what I said). (Please be careful, fumes are very dangerous).

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cleaning In Place Machine for Stainless Tanks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords