High Quality Heavy Steel Rails for Rails of Tren GB38KG, GB43KG

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering gh Quality Heavy Steel Rails for Rails of Tren GB38KG, GB43KG at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

High Quality Heavy Steel Rails for Rails of Tren GB38KG, GB43KGis suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track.Tunnel way, curve way, railway, subway, transportation track, express, etc

Product Advantages:

OKorder's High Quality Heavy Steel Rails for Rails of Tren GB38KG, GB43KG are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

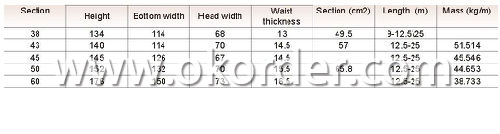

Specifications of High Quality Heavy Steel Rails for Rails of Tren GB38KG, GB43KG

Sizes: 38kg, 43kg, 45kg, 50kg, 60kg.

Production Standard: GB2585-81, DIN, AREMA, JIS, BS, UIC, etc.

Material: 50MN, U71MN, 900A, 110A, etc.

Length: 6m-25m according to the requriements of the clients

Invoicing on theoretical weight or actual weight as customer request

Package & Delivery of High Quality Heavy Steel Rails for Rails of Tren GB38KG, GB43KG

1. Package: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, size, length, grade, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the High Quality Heavy Steel Rails for Rails of Tren GB38KG, GB43KG will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Inspection of High Quality Heavy Steel Rails for Rails of Tren GB38KG, GB43KG

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

Production flow of Steel Heavy Rail

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Can fit in the containers of 20fts the High Quality Heavy Steel Rails for Rails of Tren GB38KG, GB43KG of 6M?

A1: No proble, we can put them into the containers in the form sideling.

Q2: The products are invoicing on theoritical weight or on actual weight?

A2: We can do it in both manners, according to the customers' request.

- Q:Can steel rails be used in railway signaling systems?

- No, steel rails cannot be used in railway signaling systems as they are primarily used for providing a stable track for trains to run on. Signaling systems use a variety of electrical components and technologies to control train movements, ensuring safety and efficient operation.

- Q:How are steel rails protected against derailments?

- Steel rails are protected against derailments through various measures. One common method is by ensuring proper alignment and regular maintenance of the tracks. This includes inspecting the rails for any defects, such as cracks or wear, and promptly repairing or replacing them. Additionally, the use of switches and signals helps to control train movements and prevent collisions or derailments. Continuous monitoring systems are also employed to detect any anomalies or deviations in the track, allowing for immediate action to be taken to prevent derailments.

- Q:How do steel rails handle vibrations from passing trains?

- Steel rails are designed to handle vibrations from passing trains by absorbing and dispersing the energy generated. The steel material used in rails is strong and sturdy, allowing it to withstand the repetitive loading and impact caused by the train's weight and motion. Additionally, the rails are securely fastened to the sleepers and ballast, which helps to dampen and distribute the vibrations. The overall design and construction of the railway track system work together to minimize the transmission of vibrations to surrounding structures and ensure a smooth and stable ride for trains.

- Q:Are steel rails used in industrial railways?

- Yes, steel rails are commonly used in industrial railways. Steel rails offer several advantages over other materials such as durability, strength, and resistance to wear and tear. These qualities make steel rails suitable for handling heavy loads and providing stability to trains or other industrial vehicles. Additionally, steel rails have a longer lifespan compared to other materials, reducing the need for frequent replacements. Overall, steel rails are widely utilized in industrial railways to ensure efficient and safe transportation of goods and materials.

- Q:What are the main advantages of using steel rails?

- The main advantages of using steel rails include their high tensile strength, durability, and resistance to wear and tear. Steel rails are able to withstand heavy loads and provide a stable track for trains, ensuring safe and efficient transportation. Additionally, steel rails require less maintenance compared to other materials, making them a cost-effective choice for railway infrastructure.

- Q:How do steel rails handle vibrations from passing trains?

- Steel rails are specifically designed to handle vibrations from passing trains in a highly efficient manner. The inherent properties of steel, such as its strength, durability, and elasticity, make it an ideal material for railway tracks. When a train passes over the steel rails, vibrations are generated due to the interaction between the train's wheels and the track. These vibrations can have a negative impact on the overall performance and safety of the railway system if not properly managed. Steel rails are designed to absorb and dissipate these vibrations through various mechanisms. One of the primary methods is by utilizing the elastic properties of steel. Steel has the ability to deform under load and return to its original shape once the load is removed. This characteristic helps the rails to absorb and distribute the energy generated by passing trains, minimizing the vibrations transmitted to the surrounding infrastructure. Additionally, a proper track design and construction play a crucial role in handling vibrations. The rails are fixed to the sleepers or ties using resilient fasteners, which provide a cushioning effect. These fasteners help to dampen the vibrations by allowing slight movement of the rails, reducing the impact on the surrounding structures. Furthermore, the ballast, which is the layer of crushed stone or gravel beneath the rails, acts as a shock absorber. It helps to distribute the load and dissipate vibrations, preventing excessive ground-borne vibrations from reaching nearby structures or communities. Regular maintenance and inspection of the steel rails also contribute to their ability to handle vibrations. Any defects or damages, such as cracks or wear, are identified and repaired promptly to ensure the integrity and performance of the rails. In conclusion, steel rails are designed to effectively handle vibrations generated by passing trains. The combination of steel's elastic properties, resilient fasteners, proper track design, and maintenance practices work together to minimize the impact of vibrations on the railway infrastructure and surrounding areas, ensuring a smooth and safe train operation.

- Q:Can steel rails be customized for specific needs?

- Yes, steel rails can be customized for specific needs. Manufacturers can alter the dimensions, shape, and composition of the steel rail to meet specific requirements such as weight capacity, track curvature, and environmental conditions. Customization can also include surface finishes, coatings, and additional features to enhance durability, reduce friction, or improve safety.

- Q:Can steel rails be used for magnetic levitation train systems?

- No, steel rails cannot be used for magnetic levitation train systems. Magnetic levitation trains, also known as maglev trains, rely on magnetic forces to suspend the train above the track and propel it forward. Steel rails, being made of a non-magnetic material, cannot generate the necessary magnetic forces for this type of technology. Maglev trains typically use either electromagnetic or electrodynamic systems to achieve levitation. Electromagnetic systems involve using powerful electromagnets on the train that are attracted to a series of magnets embedded in the track. By controlling the magnetic fields, the train can be levitated and propelled forward. Electrodynamic systems, on the other hand, utilize the principle of electromagnetic induction. The track is equipped with coils that create a changing magnetic field, which induces currents in the train's conductive underside. These currents then generate magnetic fields that repel the track, causing levitation. Both of these maglev technologies require specific materials and designs to create the necessary magnetic fields and forces. Steel is a ferromagnetic material, meaning it can be magnetized, but it is not a suitable choice for maglev systems due to its relatively weak magnetic properties. In fact, steel rails would interfere with the magnetic fields needed for levitation and propulsion, resulting in inefficient operation and diminished performance. Instead, maglev train systems typically employ materials like superconducting magnets or permanent magnets, which are much more efficient in generating the required magnetic fields. These materials are carefully engineered to provide stable levitation and efficient propulsion, allowing maglev trains to achieve high speeds and smooth rides.

- Q:Can steel rails be installed on uneven terrain?

- Yes, steel rails can be installed on uneven terrain by using appropriate construction techniques such as leveling the ground, adding ballast, and adjusting the track alignment to ensure stability and smoothness of the railway system.

- Q:What is the rail temperature stress?

- Thermal stress is also called thermal stress". Stress due to the temperature rise and fall of a body or the temperature of each part of an object. For example, the workpiece is welded by the stress caused by local heating; there is a gap between the rails of the rails to avoid or reduce the possible temperature stress.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality Heavy Steel Rails for Rails of Tren GB38KG, GB43KG

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords