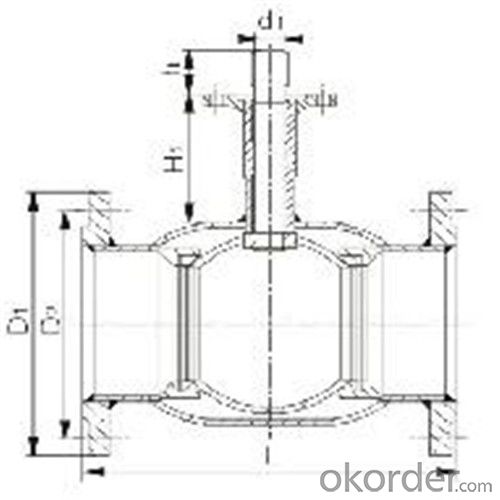

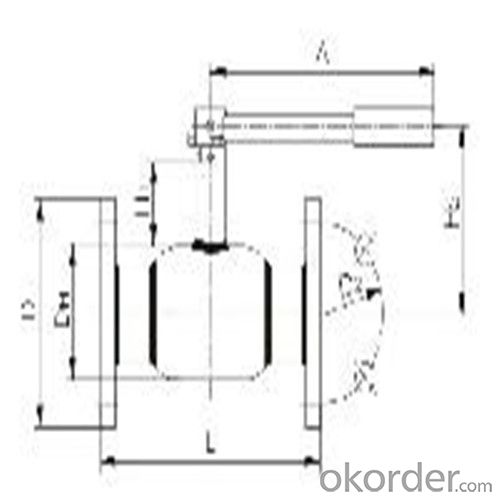

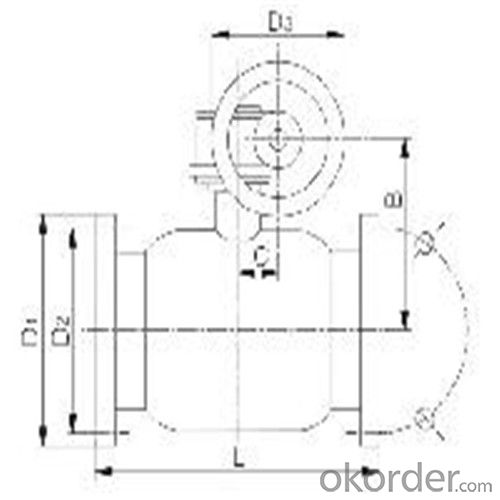

Ball Valve For Heating SupplyDN 150 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ball Valve For Heating Supply

Product Description of Ball valve for heating supply:

Technical introduction

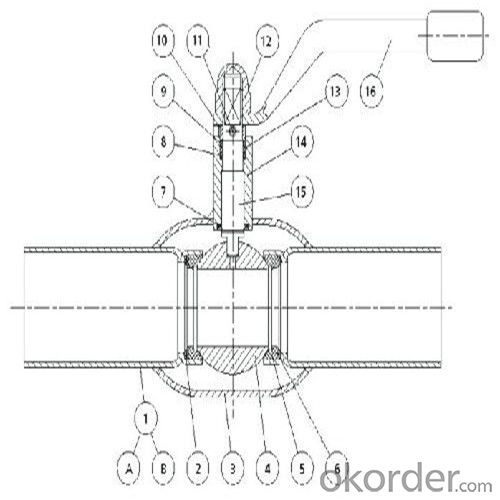

★The ball valve is designed as fully welded structure,which can prevent the leakage of medium.

★The valve seat is floating and spring-loade.The seal is made of soft seal materials of PTFE+20%C and Viton B.The seat is tightly abutted against the ball surface by the pressure of a spring,so that even if the media is in low pressure,a reliable sealing can be assured for the ball valve.Double piston effect and double seal(two-seal seat)are adopted in specially designed valve seat to realize double sealing,which makes the tightness of the ball valve more advantageous and the operation easier.

★A floating ball is adopted for DN15-DN200,and a stem and trunnion ball is adopted for DN200 and above,which can ensure the accurate position of different size ball.In other words,the sealing performance,low torque valve and operability can be guaranteed.

★The sealing of the stem is fulfilled by two replaceable O-rings and packing consisting of PTEE+20%C or flexible graphite,as the packing seal material,is fire proof effect,and is specially suitable for fuel gas systems.

★The materials used for the valve body and pipelines are the same(carbon steel or SS steel),valve body and stem adopt SS steel and the packing adopts PTEE+20%C which is corrosion-resistance or flexible graphite.

Design Features of Ball valve for heating supply:

Features and Applications

Raymond's fully welded ball valve for heating supplyand Fuel Gas systemare used to control the flow at fully open or closed position,not regulate the flow.Only special types of ball valves can realize the flow regulation.Therefore,our welded ball valves can satisfy the requirements of heating systems,e.g:

★Main pipelines of heating equipment

★Cross channels of heating pipes

★Heat exchanger station and any long distance operating station,e.g:

For the transmission of hot water and two kinds of mixed media(water,air or natural gas),limited to Max.4.0MPa and 200°C.

For the transmission of natural gas and one medium,from -30°C to 60°C,and even up to 150°C using specially designed ball valves.

★Coal gas pipelines,trunk and the branch supply lines.

Standard of Ball valve for heating supply:

Actuator | Gear Handwheel customize |

Connection | Flange SW Weld customize |

Medium | Gas Natural gas Water customize |

Medium Temperature | <200< span="">℃ customize |

Application Fields | Electricity Medical Petrochemical customize |

Connection Standard | EN 1092-1 EN 12627 ISO 7-1 customize |

FAQ of Ball valve for heating supply:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: Yesterday,my friend told me his ball valve in garden was broken. He want me to help he find a useful ball valve. I find some webs, but not he want. So I want somebody to help me find the useful ball valve. Thanks.

- You can now easily order or buy ball valve from Kusha Steels. They highly produce A-1 quality products, Have personally ordered their products several times.

- Q: i'm being charged $300 to replace a 75gallon water heater valve, is that too much?

- Well the issue here they have to drive over, drain the tank, change the valve. The way I see it you at an easy 250.00. So 300 is not out of line. And if the water heater is over 10 years old, I would strongly consider replacing it vs the repair. That heater is expensive I would inquire about if that part is under warranty. But that price I hate to say is somewhat in line.

- Q: I have a 40 year old Holton Bb trumpet. It plays fine except the first valve always gets stuck when I play it, in the middle of a song it won't come back up. I can pull it back up and it doesn't get stuck real bad, but how can I fix this? I always oil it properly and insert the valves right. Do I have to replace it? Thanks

- You need not replace the valve, but it does need a bit of attention. There are many possible reasons for the sticking and you can spend a long time trying to chase them down. Inconsistent sticking suggests 2 likely reasons (there are several more possible reasons). The first is piston wear that has slightly misshapen the valve casing so it sticks because it doesn't travel through the valve casing exactly the same way every time. The second is that the felts and corks are worn and need to be replaced. The best thing for you to do is to take it to a shop, describe the problem and spend a few bucks to get it fixed right.

- Q: Today I found out I have the heart disease Mitral Valve Prolapse. I'm 13, I weigh 109 pounds and I'm 5'8. I'm also pretty skinny too. I know this is a pretty common disease but should I be worried at all?

- Normally, no it is not something to worry about overtly. However if you are not treated properly and not monitored then things can get worse. Your weight actually fits in with MVP as most people with MVP have a low BMI and are quite lean and skinny. If your doctor has put you on a care programme, great if not, voice your concerns to them!

- Q: I got a cold air intake installed on my vehicle and don't have any AEM bypass valve installed, for preventing hydrolock. If I drill a small hole(e.g 1cm) on the intake(short ram section) can that prevent hydrolock or do I still have to get one of those bypass valves?I'm looking for any alternatives, instead of those AEM bypass valves and was wondering if drilling a small hole in the cold air intake could help in preventing hydrolock, just as good as the AEM bypass valve.

- if you drill a hole in your intake, your gonna have a air leak and thats the last thing you want, you dont have to have a bypass valve , u only need it when its raining

- Q: where is the fuel tank selector valve located on the truck?

- There is no selector valve on 1992-95 F150's. There were or the older carbureted trucks but newer ones are all fuel injected and have in-tank fuel pumps. The switch on the dash just selects which pump you turn on. I'd say the front tank fuel pump has gone bad or possibly has a cheaper electrical problem (if you're lucky). Exact same thing happened to my 1995 F150. Replacing a pump is a pain and not cheap.

- Q: Can leakage of heart mitral valve be treated with homeopathic medicines?My grandmom has leakage in mitral valve. I am searching for options to other than surgery to make it less painful for her. She' is above 80yrs of age. If you know of any good options for treatment , please let me know as we also consult the doctors. thank u :)

- There is a significant amount of scientific evidence that mitral valve prolapse (leakage) is caused by magnesium deficiency. It is therefore treatable by proper magnesium therapy. Below is a link to the world's leading research journal on magnesium and a paper on this issue. www.ncbi.nlm.nih /pubmed/15945... Best wishes and good luck.

- Q: I have several stations in my automatic lawn sprinkler system. Each station has a valve that contains: 1. Manual Shutoff, 2. Flow Control Knob, 3. Solonid, 4. Anti-Siphon valve. Any way my question is this, Why does water continue to flow even when the manual shutoff is turned off and the flow control is also turned off?

- Any manual shutoff should shut the zone down completely, a flow control will limit the volume of water that leaves the valve by resticting the valve diaphram movement. If neither is working they may not be operational. A zone that continually runs either has a plunger stuck in the solenoid, a ruptured diaphram in the valve, or debris between the diaphram and valve body. If all these are contained in the valve, the most likely cause would be a bad diaphram or debris keeping the valve from closing completely

- Q: i have been told that a bad EGR valve (exhaust gas recirculation valve) could cause a car to buck or hesitate in mid range speed at low rpms, thats what my car is doing. i work at autozone and i used our code reader and there was a code that stated EGR flow malfunction anyone else have this problem ever? please help me! i dont wanna spend the $120 if i dont need to!

- If an egr valve opens too soon you will have a hesitation problem. Bad egr's do not cause problems with drive-ability at cruising speed. It sounds like your egr is faulty.

- Q: Can someone please explain the difference between a pressure tap valve and a gate valve (if any).

- this will explain about a gate valve e

Send your message to us

Ball Valve For Heating SupplyDN 150 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords