Ball Valve For Heating SupplyDN 50 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ball Valve For Heating Supply

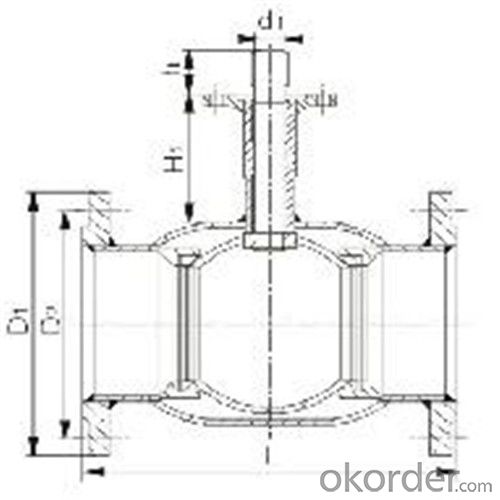

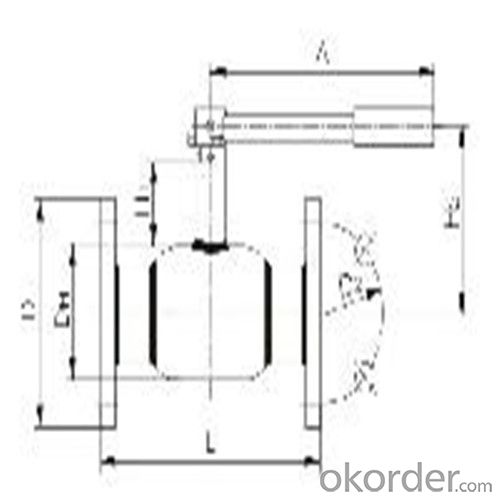

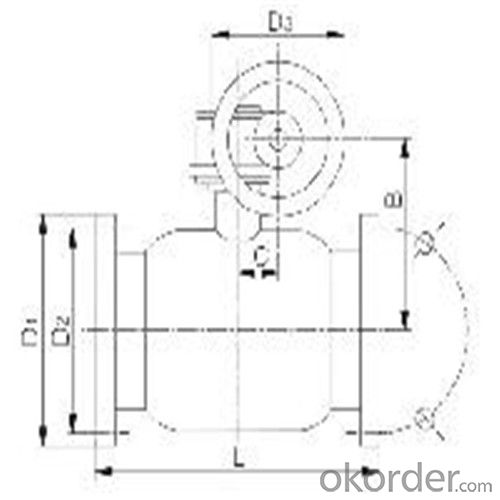

Product Description of Ball valve for heating supply:

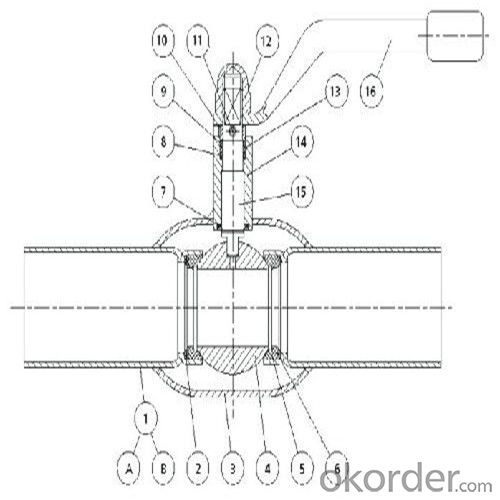

Technical introduction

★The ball valve is designed as fully welded structure,which can prevent the leakage of medium.

★The valve seat is floating and spring-loade.The seal is made of soft seal materials of PTFE+20%C and Viton B.The seat is tightly abutted against the ball surface by the pressure of a spring,so that even if the media is in low pressure,a reliable sealing can be assured for the ball valve.Double piston effect and double seal(two-seal seat)are adopted in specially designed valve seat to realize double sealing,which makes the tightness of the ball valve more advantageous and the operation easier.

★A floating ball is adopted for DN15-DN200,and a stem and trunnion ball is adopted for DN200 and above,which can ensure the accurate position of different size ball.In other words,the sealing performance,low torque valve and operability can be guaranteed.

★The sealing of the stem is fulfilled by two replaceable O-rings and packing consisting of PTEE+20%C or flexible graphite,as the packing seal material,is fire proof effect,and is specially suitable for fuel gas systems.

★The materials used for the valve body and pipelines are the same(carbon steel or SS steel),valve body and stem adopt SS steel and the packing adopts PTEE+20%C which is corrosion-resistance or flexible graphite.

Design Features of Ball valve for heating supply:

Features and Applications

Raymond's fully welded ball valve for heating supplyand Fuel Gas systemare used to control the flow at fully open or closed position,not regulate the flow.Only special types of ball valves can realize the flow regulation.Therefore,our welded ball valves can satisfy the requirements of heating systems,e.g:

★Main pipelines of heating equipment

★Cross channels of heating pipes

★Heat exchanger station and any long distance operating station,e.g:

For the transmission of hot water and two kinds of mixed media(water,air or natural gas),limited to Max.4.0MPa and 200°C.

For the transmission of natural gas and one medium,from -30°C to 60°C,and even up to 150°C using specially designed ball valves.

★Coal gas pipelines,trunk and the branch supply lines.

Standard of Ball valve for heating supply:

Actuator | Gear Handwheel customize |

Connection | Flange SW Weld customize |

Medium | Gas Natural gas Water customize |

Medium Temperature | <200< span="">℃ customize |

Application Fields | Electricity Medical Petrochemical customize |

Connection Standard | EN 1092-1 EN 12627 ISO 7-1 customize |

FAQ of Ball valve for heating supply:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: My Rodeo 96 has a P0440 code (Evaporative Emissions Control System problem). I have visually inspected the hoses on the engine; double-checked the gas cap is tight; but have not looked at the fuel tank sensors and connections. I've noticed that the EVAP canister purge valve solenoid is switching non-stop (click-click-click noise without stopping). Is it the expected behavior?

- P0440 Isuzu Rodeo

- Q: Glob Valve or Gate Valve

- Gate valve is commonly used.

- Q: My mother was dx'd with Mitral Valve Prolaspe 20 years ago....she use to take meds for it. My question is she is having very bad fatique symptoms.. uld this be caused from her MVP getting worse???

- first of all, if she is on atenolol (tenormin) then you have to take a pulse before meds and hold med if it is 60 beats per min. if she had trouble with her meds and stopped them for this reason then she should get back on them, and yes mitral valve prolapse is fairly common but is not something you want to ignore or stop treatment for, if she if feeling fatigued she should get checked again, she could have other heart problems. plz have her see a cardiologist ASAP

- Q: whaT ARE THE SYMPTON OF A BAD EGR Valve Position Sensor loss of power ?1998 toyota camry v6

- Typically when those sensors start to go bad, the EGR valve doesn't modulate properly between open and closed. When that happens you usually notice a sort of fluttering in the power delivery, often when cruising at a set speed but sometimes also when accelerating as a result of the wrong amount of exhaust gas being recycled back into the engine. You sometimes will notice a loss of power when accelerating as well. If the EGR valve is opening more than necessary it will be allowing more exhaust gas back into the engine than is beneficial....and that will reduce the amount of power the engine produces. If the EGR valve is staying closed more than necessary, you might not notice as many driveability issues but you'll probably notice your average fuel mileage decreasing a little and/or a check-engine light being triggered and/or a failure of an emissions test (even if the check engine light hasn't tripped) if you live somewhere that emissions checks are required.

- Q: i recently adjusted my valves on my 01 civic with a 1.7 sohc vtec motor and i did it to the specs under the hood and i didnt have them too tight or too loose on the feeler gauge and they are pretty loud are these motors just that noisy? has anyone else adjusted them to something different that works better?

- The dude above is physically powerful, yet incorrect on the fee. you may get an entire swifter equipment for about 1k, a reliable setup will fee a million.5k to 2k with injectors, gasoline pump, a turbine, and an intercooler. 01 are heavy and not super to do mods to, additionally d16 sucks inventory, so which you're able to additionally could desire to yet internals with expenses 900 for the aspects (pistons and rods). entire could be 2k to 3k for an extremely super setup for 250 to 300hp

- Q: hi friends i want to know about the calibration technque of foundation fieldbus based control valve by a analog source

- * okorder moreinfo

- Q: My grandfather is going in for a valve replacement.. and I'm really worried about him.. I just want some information.. any good websites if you have them.. I looked on google.. But if you have any good ones that would be great..No horrible comments please..

- I don't know much about it, but as far as I know, it's become a relatively routine procedure. Personally, the surgeon I'd want to do it on me is the guy who does 20 or more of them a week, instead of the guy who does two a month. The more frequently they do the procedure, the more adept they are at it, do you know what I'm saying? Good luck! I'm sure your grandfather'll do fine!

- Q: Just bought car used. It is an 88 Toyota Corolla Fx. It is leaking and loosing a lot of oil. The EGR valve is spraying pretty badly. All hoses are fine. Seems to be in the seal. Is this the possible fix I need to solve these problems? Cleaned and inspected engine for other leaks and found none. Please help. Very poor and highly motivated to fix this car up.

- Hello, The EGR valve will not spray oil, It is an exhaust gas recirculation valve that does not have oil get to it!! Please add more info so we can better answer your question . Thanks for additional info. But I don't think you know what the EGR valve is. Engine oil should not be spraying from the EGR valve ! Maybe you are trying to describe another part? Also, You need to fix the wheel cylinder or caliper before you can bleed the brakes. Maybe you need a mechanic to assist you. Good luck !

- Q: hello!I'm designing a floor cleaner and for a water release system i was thinking of using a ball valve, connected to an actuator,however i'm not fully sure what to look for, and although I can buy the actuator and ball valve together, I'm not sure how to connect it to a motor and battery?If anyone can help my with this I'd really appreciate it!!Thank You!!

- An actuator for a ball valve can use either compressed air or an eectric power source to drive a motor. Air actuated valves can operate very quickly and are a little cheaper but they require a compressed air source and pneumatic controls to operate. An electric operator uses a geared motor to operate the valve and are slower. Electric operators are more expensive but only require power and some switches to operate. See link for hook up details.... The motor is built into the actuator so its just a matter of mating the actuator up with the valve. It would be best to buy a complete unit with the actuator and valve already attached. These will cost at a minimum several hundred dollars. Using a ball valve may not operate fast enough nor give you fine control if your considering using it to control the cleaning fluid applied to the floor. Instead consider using a solenoid valve instead. These are smaller valves and operate very quickly by just adding or removing power. Not to mention these are much cheaper $25 to $100 on average.

- Q: My doctor detectd a heart mumer. I am 48 years old. Had a echocardiogram performed. He says that I have a sightly irregular valve and I do not need to take precautions. I run three miles a day. I have heard that this condition makes your heart more suceptiable to infection. You should take antibiotics when dental work is done. My GP is a man of few words. Just says continue as usual and nothing needs to be done unless there is further symptomns. My question: Should I follow up with a heart specialist or would it be over doing it? Should I go on antibiotics when I get dental work? Can this Slightely irregular valve get worse?

- Actually this is quite common and is usually not a concern. It is generally felt that the misshapen valve leaves you more open to potential infection, especially when having dental work done. But this is quite rare. Still, if the dentist knows you have the condition they will require you to take a loading dose of antibiotics to protect yourself when you have any work done. Occasionaly I would forget and they would send me home. Geeze. Still, better safe than sorry. In the big scheme of things it means very, very little and you will probably never know its there. There is no need to see a specialist, again, this is very common and very, very rarely causes any problems. Just keep on keeping on and you will be fine. Just consider the antibiotics pre-dental work. All you have to do is call the doctors office, tell them you need some for a dental visit, they will fax over a script to the pharmacy, you pick it up, eat something first, then take the antibiotics and you are done, no big deal. I hope this helps.

Send your message to us

Ball Valve For Heating SupplyDN 50 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords