Ball Valve For Heating SupplyDN 100 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ball Valve For Heating Supply

Product Description of Ball valve for heating supply:

Technical introduction

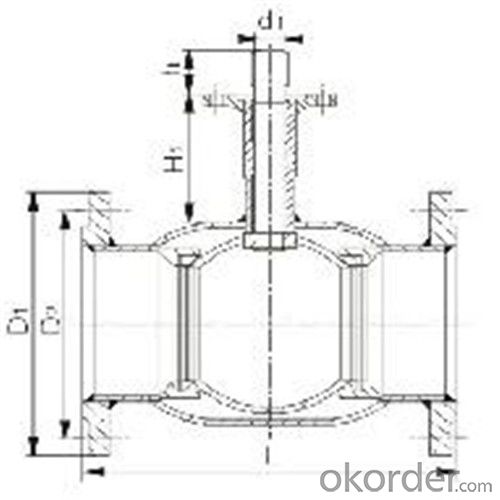

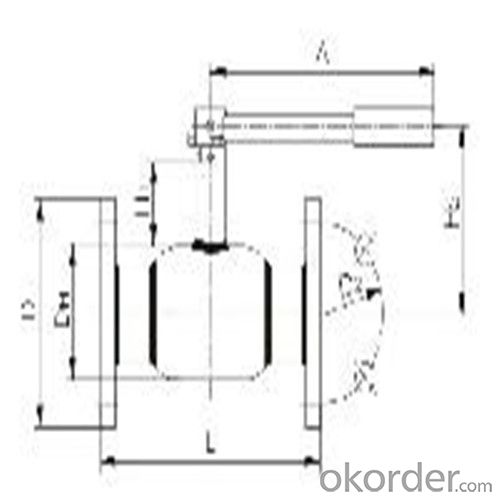

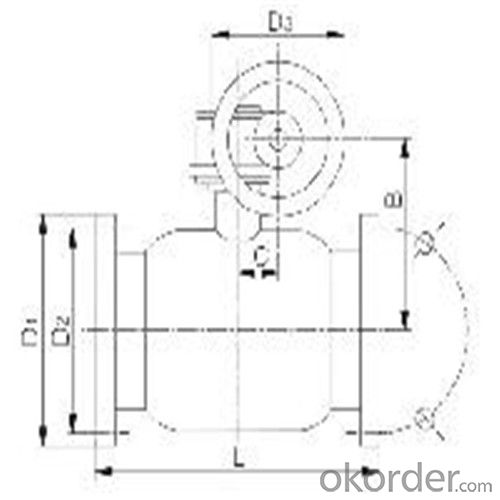

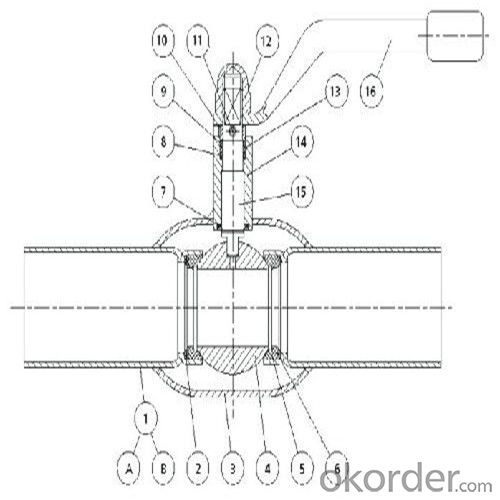

★The ball valve is designed as fully welded structure,which can prevent the leakage of medium.

★The valve seat is floating and spring-loade.The seal is made of soft seal materials of PTFE+20%C and Viton B.The seat is tightly abutted against the ball surface by the pressure of a spring,so that even if the media is in low pressure,a reliable sealing can be assured for the ball valve.Double piston effect and double seal(two-seal seat)are adopted in specially designed valve seat to realize double sealing,which makes the tightness of the ball valve more advantageous and the operation easier.

★A floating ball is adopted for DN15-DN200,and a stem and trunnion ball is adopted for DN200 and above,which can ensure the accurate position of different size ball.In other words,the sealing performance,low torque valve and operability can be guaranteed.

★The sealing of the stem is fulfilled by two replaceable O-rings and packing consisting of PTEE+20%C or flexible graphite,as the packing seal material,is fire proof effect,and is specially suitable for fuel gas systems.

★The materials used for the valve body and pipelines are the same(carbon steel or SS steel),valve body and stem adopt SS steel and the packing adopts PTEE+20%C which is corrosion-resistance or flexible graphite.

Design Features of Ball valve for heating supply:

Features and Applications

Raymond's fully welded ball valve for heating supplyand Fuel Gas systemare used to control the flow at fully open or closed position,not regulate the flow.Only special types of ball valves can realize the flow regulation.Therefore,our welded ball valves can satisfy the requirements of heating systems,e.g:

★Main pipelines of heating equipment

★Cross channels of heating pipes

★Heat exchanger station and any long distance operating station,e.g:

For the transmission of hot water and two kinds of mixed media(water,air or natural gas),limited to Max.4.0MPa and 200°C.

For the transmission of natural gas and one medium,from -30°C to 60°C,and even up to 150°C using specially designed ball valves.

★Coal gas pipelines,trunk and the branch supply lines.

Standard of Ball valve for heating supply:

Actuator | Gear Handwheel customize |

Connection | Flange SW Weld customize |

Medium | Gas Natural gas Water customize |

Medium Temperature | <200< span="">℃ customize |

Application Fields | Electricity Medical Petrochemical customize |

Connection Standard | EN 1092-1 EN 12627 ISO 7-1 customize |

FAQ of Ball valve for heating supply:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: i would like to hear from anyone who has actually had the work done. i also would like to know if the valve worked.

- I suggest putting this question anywhere but in cars and transportation.

- Q: Hi, I have Orbit valve for a section of my yard. The pressure is really low when I turn it on with my remote. When I turn it on manually at the valve, the water pressure is much higher.

- Its possible the valve stem is corroded with stuff not letting it actuate properly open. Turn water off and unscrew the valve then actuate it electrically while watching for a full stroke. Make sure flow control is all the way open when inspecting valves stroke. Remember where you had it set when done or readjust. Also check the solenoid for corrosion and clean linkages. I would clean and coat with petroleum jelly. My guess is valve seat is gummed up so lube the stem and work it manually till it slides open and closed easy then test with the solenoid. Good luck!

- Q: How can I tell if my 2004 Ford Taurus a 12 or 24 valve?

- I may be wrong but I think the 24 valve engines had a little badge on the body of the car that said 24 VALVE. Another thing that might help is look at the engine information on the white tag under the hood.

- Q: I'm in the process of replacing my dishwasher but I have a problem. I followed the water line from the dishwasher to under my sink and found a red valve that was completely straight, so I turned it to the right as tight as it would go and tried removing the hex nut connecting the line to the dishwasher. Maybe i'm wrong, but there is a lot of water coming out of the line and I don't think it's supposed to. I easily filled up a bowl you would use to mix cakes and it was still going! So, I turned the valve back to straight across thinking maybe someone else turned it off (my dad), and tried it again but the same thing? What am I doing wrong and what should I do to solve this?

- If it is a quarter turn valve , the lever should be across ed the valve ,not in line with it. If that's not working for ya, turn the main water valve off. then drain the water pressure by opening the faucet at the highest point and the lowest point in the house. now it's time to change the dish washer. Good luck it shouldn't be that hard.

- Q: will a blow off valve work with out an intercooler???(civic 2000)and also, is a blow off valve a turbo?whats the diffrence between a turbo and a blow off valve?? thankss..

- A blow off or pop off valve controls the boost or pressure the turbo or supercharger is pushing into the engine.A turbo makes the boost.The blow off valve controls it so you wont run too much boost or pressure into your engine and leave pieces of it all over the street.The blow off valve can be adjusted to control the boost,6- 8 lbs.should be sufficient for a street application.The blow off valve simply allows the excess pressure built up in the turbo to be vented or blown off so it wont be forced into the engine.The boost on a supercharged or blower application is controlled by swapping the blower pulley to either underdrive the blower or overdrive the blower,depending on which way you want to go.

- Q: Where is the PCV valve located on 2001 Nissan Altima

- Follow the line out of the bottom of the flux capacitor and you'll run right into it. The PCV valve on Altimas looks different than what has been common for years on most engines. The PCV valve is located at the drive belt side of the engine under the intake manifold and attached to the breather/separator. Access from above is very difficult; access the valve from underneath the vehicle. There is a short hose that connects to the breather/separator. Remove the breather/separator and the hose. Then you can unscrew the PCV valve from the breather/separator for easy inspection and cleaning of each piece. Also inspect both passages where the separator and hose connect. Here is a picture of the valve after it is removed. The breather/separator is a small aluminum housing that will fit in your hand.

- Q: also are those air flow limiting valves safe for the air pump to reduce the flow of air, I have one because the air bubbles are just way too many without one and it scares the fish away

- a check valve is to prevent back siphoning of water into the pump if you have a power outage or unplug the pump by accident. I'd suggest checking it by blowing through it the wrong way; if air does pass through get a new check valve (check new ones to be sure they don't limit airflow too much, and that the close in the wrong direction, many are cheap crap and don't work the day you buy them, so check them before you leave the store with it...note: same with thermometers, compare them with each other so you don't get the one that's crap) what you want is a normal air valve, they come in various configurations, one or more valves so as to run multiple airstones and to balance the airflow to each stone or ornament. You should not however just use the valve to limit airflow, as this damages the pump eventually. You can just let one of two valves bleed off a little air; however make sure another check valve is in the line from the tank to the valves or else you risk water coming out of that valve if it's lower than the tank water level.....You may want a smaller air pump or an adjustable one instead.

- Q: Describe a typical semilunar valve and tell how it works

- The semilunar valves are located between the aorta and the left ventricle and between the pulmonary artery and the right ventricle.(aortic valve and pulmonary valve) The semilunar valves are flaps of endocardium and connective tissue reinforced by fibers which prevent the valves from turning inside out. They are shaped like a half moon, hence the name semilunar (semi-, -lunar). they prevent the back flow of blood to left and right ventricles respectively.

- Q: Why can't i start my valve?

- what kind of valve are you talking about? A Valvo?? LOL...No really, what kind of valve? Valves do not start, once the engine is fired up then the valve becomes a part of the engines 4 cycle system of opening and closing to allow fuel and air to enter inside the combustion chamber and ignite the fuel to keep the engine running. good luck..

- Q: The pig heart is better than our heart but the valves can be used to help us.

- now days there are vavles used that are man made

Send your message to us

Ball Valve For Heating SupplyDN 100 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords