Ball Valve For Heating SupplyDN 80 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ball Valve For Heating Supply

Product Description of Ball valve for heating supply:

Technical introduction

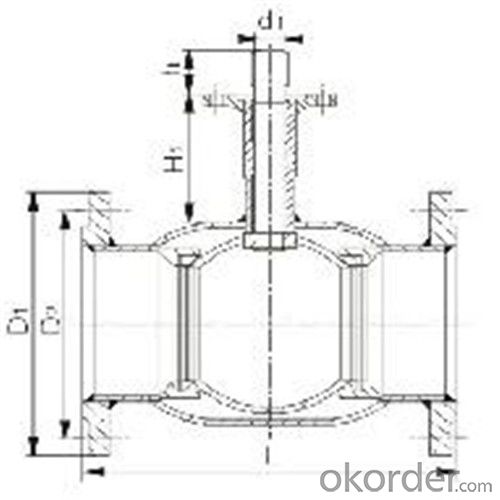

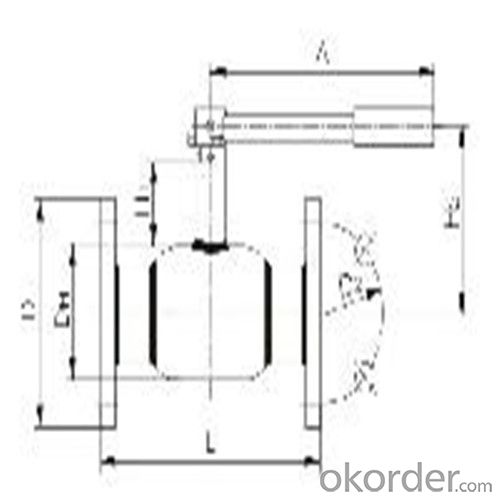

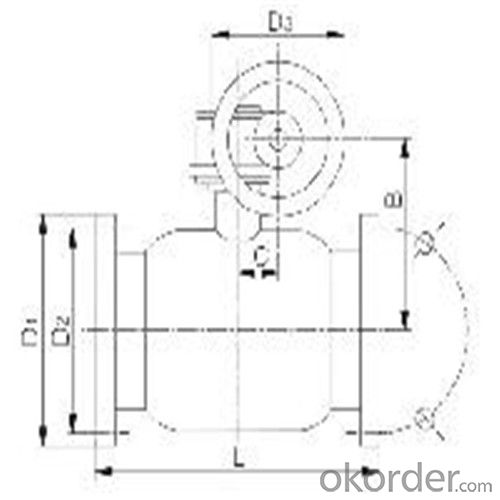

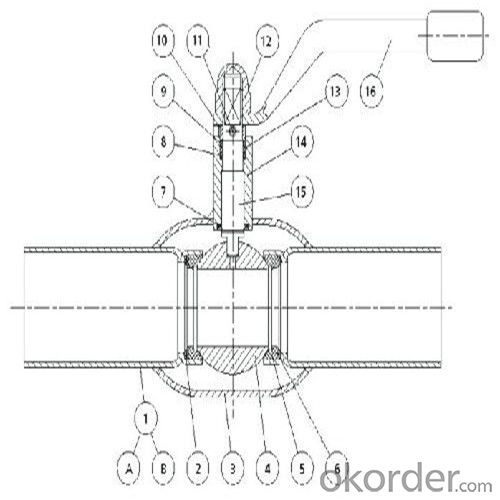

★The ball valve is designed as fully welded structure,which can prevent the leakage of medium.

★The valve seat is floating and spring-loade.The seal is made of soft seal materials of PTFE+20%C and Viton B.The seat is tightly abutted against the ball surface by the pressure of a spring,so that even if the media is in low pressure,a reliable sealing can be assured for the ball valve.Double piston effect and double seal(two-seal seat)are adopted in specially designed valve seat to realize double sealing,which makes the tightness of the ball valve more advantageous and the operation easier.

★A floating ball is adopted for DN15-DN200,and a stem and trunnion ball is adopted for DN200 and above,which can ensure the accurate position of different size ball.In other words,the sealing performance,low torque valve and operability can be guaranteed.

★The sealing of the stem is fulfilled by two replaceable O-rings and packing consisting of PTEE+20%C or flexible graphite,as the packing seal material,is fire proof effect,and is specially suitable for fuel gas systems.

★The materials used for the valve body and pipelines are the same(carbon steel or SS steel),valve body and stem adopt SS steel and the packing adopts PTEE+20%C which is corrosion-resistance or flexible graphite.

Design Features of Ball valve for heating supply:

Features and Applications

Raymond's fully welded ball valve for heating supplyand Fuel Gas systemare used to control the flow at fully open or closed position,not regulate the flow.Only special types of ball valves can realize the flow regulation.Therefore,our welded ball valves can satisfy the requirements of heating systems,e.g:

★Main pipelines of heating equipment

★Cross channels of heating pipes

★Heat exchanger station and any long distance operating station,e.g:

For the transmission of hot water and two kinds of mixed media(water,air or natural gas),limited to Max.4.0MPa and 200°C.

For the transmission of natural gas and one medium,from -30°C to 60°C,and even up to 150°C using specially designed ball valves.

★Coal gas pipelines,trunk and the branch supply lines.

Standard of Ball valve for heating supply:

Actuator | Gear Handwheel customize |

Connection | Flange SW Weld customize |

Medium | Gas Natural gas Water customize |

Medium Temperature | <200< span="">℃ customize |

Application Fields | Electricity Medical Petrochemical customize |

Connection Standard | EN 1092-1 EN 12627 ISO 7-1 customize |

FAQ of Ball valve for heating supply:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: Hi....my boyfriend is currently waiting to have heart valve replacement surgery and im a little worried about the whole thing...he doesnt like talking about it but if someone knows the answer to my questions I'd be so greatful!!First of all a little detail....he is 19, as far as i know he was born with this problem with his valve but it has got worse over time. he was also born with a hole in his heart but had an operation as a baby to fix this. he gets short of breath and often has pains in his chest. he says hes going to have a pigs heart valve to replace his, by open heart surgery (in a few months time). my main worry is whether the operations are always successful? and will this condition/operation affect his life expectancy??please if there are any experts in the field help put my mind to rest....!thanksshelly x

- Open heart surgery is always a risk, as is any major surgery. The main risks are from infection and blood clots. The risks taper off very quickly within a few days after the surgery. Heart valve replacements are a common operation, with a high success rate. Life expectancy is generally better with a valve replacement; but not all valve problems reduce life expectancy to begin with. Sometimes the trade-offs are more of an issue with quality of life, with higher quality achieved with a functioning heart valve, so some people may be taking a medical risk to obtain higher quality of life. No one can tell you for certain what the outcome of this operation will be. The odds are very high that everything will go perfectly and he will fell better than ever before. There is a very small chance that he will end up worse To put the risks in perspective, a person i know had minor surgery to her knee - a simple 1 hour operation done at an outpatient clinic. Ten days later, a clot broke loose and she died in her sleep. I have had the same operation twice and didn't even miss more than a few hours of work. Another person i know had severe heart problems and docs said it was terminal, but an operation could prolong his life maybe 5-7 years. He had the operation and its now been almost 20 years and his cardiologist says his heart is healthy and there's no reason why he might not live another 20 years or more.

- Q: how do i adjust the valve lash my book sys to torque to 136 in lbs but my wrench is only in ft lbs

- as stated by another valve lash is the gap space between the rocker arm end and the valve top. I too recomend getting an inch pound torque wrench especially when setting a ft lb wrench to 11.33 would be very rough.(not accurate)

- Q: Is a Head gasket the same thing as the valve cover gasket, on my honda civic si?

- no a head gasket fits betweem the head an the block. the valve cover gasket goes on the cover over the valves or rocker cover are same its sits on the very top of engine

- Q: i recently adjusted my valves on my 01 civic with a 1.7 sohc vtec motor and i did it to the specs under the hood and i didnt have them too tight or too loose on the feeler gauge and they are pretty loud are these motors just that noisy? has anyone else adjusted them to something different that works better?

- The dude above is physically powerful, yet incorrect on the fee. you may get an entire swifter equipment for about 1k, a reliable setup will fee a million.5k to 2k with injectors, gasoline pump, a turbine, and an intercooler. 01 are heavy and not super to do mods to, additionally d16 sucks inventory, so which you're able to additionally could desire to yet internals with expenses 900 for the aspects (pistons and rods). entire could be 2k to 3k for an extremely super setup for 250 to 300hp

- Q: what is a silicone purge valve.

- There are a number of things that will Toss out and ERG code on Fords (another reason I will never own another ford as long as I live) Double check all joints around the EGR valve and the tubes that connect too it. You may have a pin hole in one of the tubes or a loose coupler. If everything checks out there. Verify the vacuum line going to the EGR is not cracked, rotted, broken, or clogged. If it is replace the line. Next you need to check and make sure the valve is opening at the correct time. If the EGR is slow to open, becomes stuck half way or is opening to quickly, these will all toss out EGR codes. Then there is the possibility that the tubes for the EGR, or the EGR it's self may be clogged as well. In which case you need to remove them and clean them out. Hope this helps in your trouble shooting. Good luck.

- Q: Hi, I'd like to control a three way solenoid valve like this one:understanding is that an electric current through the solenoid will cause the valve to let air one way while no electric current will have the air flow the other. Is there a piece of equipment like a control box (that can communicate w/ a computer) that would allow me to control the solenoid valve like this? and if so, where would i be able to find something like this....i've googled but no success. I eventually want to control the valve from a computer. Thanks

- www.okorder /

- Q: My washing machine had hot and cold water, but was leaking. I changed the inlet valve which stopped the leak, but now I have no hot water. When I put the setting on warm, the cold water runs for a bit. Then stops and no hot water comes. Any help?

- I suspect the leaking valve that was replaced was your washer's solenoid valve. Did you remember to turn the hot water supply valve on after you finished? That is the valve, next to the cold water supply valve, on/at the wall behind the washer. There are rubber hoses coming from those valves to the solenoid valves on your washer. If you forgot to turn it back on after replacing the leaking valve you'll get no water. If you turn off both the hot and cold supply valves on the wall you should be able to remove the rubber hoses right where they connect to the machine and check the water flow by directing them into a bucket or pan while you open the supply vales. If you have good pressure and flow make sure there is no debris clogging the screen, just inside there the hose connects to your machine. These can get blocked where the water won't pass or runs very slow. Sometimes it pays to check the simplest causes first. Good Luck. SS.

- Q: Is it hereditary? My dad had a bicuspid valve and we got told it was hereditary but some doctors say it's not, my parents wanted to get me tested in case i had it so we would know in advance but the doctors here refuse to do it (I live in England if that makes a difference) my dad said he would pay to go private if it's hereditary. I know someone who had a bicuspid valve and 3 out of her 4 children inherited it, i know it's pretty harmless until i reach an older age but my parents and i would like to know now, i'm 13 by the way.=]

- it is hereditary sometimes, but sometimes its just a fluke. Im 16 and i have a bicuspid valve and there is no history of this in my family. and yes it will most likely be no problem for you till you get older, if at all most people dont have any problems and will be totally normal, but get it checked just in case because there could be other heart problems caused by it. I have a bicuspid aortic Valve, and aortic stenosis(which is because of the bicuspid valve) which then led to aortic back leak, and then all of those led to be getting an enlarged aorta. Most people do NOT get all these problems, but you never know. Good luck

- Q: i have a leaky tp valve on my hot water boiler. The valve is rated at 30 psi and 155,000 btu. I can't find one with that btu rating. will a higher rating work?

- Don't go by the the old valve, look at the specification tag on the boiler. Do not exceed the temp or pressure rating. If you do, you will only create a time bomb and a big one at that. In no circumstances should you use a valve with a higher rating than the heater!

- Q: I have a intake valve leakage in both my car and truck. If there some sort of quick fix i could use to stop the leakage for about 1 month.

- IF the valves are correctly adjusted, then the only solution is a valve job. Certain vehicle engines are more prone to burning valves than others.

Send your message to us

Ball Valve For Heating SupplyDN 80 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords