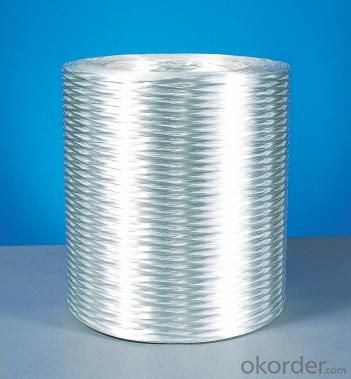

AR Glassfiber Spray Roving for Concrete

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 18MTS watt

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of AR Glassfiber Spray Roving for Concrete:

1,Diameter:15Micron

2,Linear density:2400tex

3,Package:by pallet

Description of AR Glassfiber Spray Roving for Concrete:

Alkali-resistant fiberglass spray uproving is made of AR strand,it has significant alkali resistance because containing ZrO2 composition.

Product Specification of AR Glassfiber Spray Roving for Concrete:

ARC15-2400-14.5/16.5

AR: Alkali resistant glass

C:continuous fiber

15:fiber filament diameter

2400:roving yarn density

14.5/16.7:ZrO2 content

Features of AR Glassfiber Spray Roving for Concrete:

1,No fuzz,easy chopped

2,Good integrity,dispersibility

3,Good alkali-resistant and corrosion-resistant persistence

Typical applications of AR Glassfiber Spray Roving for Concrete:

Alkali-resistant fiberglass is the Inorganic fibers,mainly used for fiberglass enhancing cement contrete,the ideal substitute for steel and asbestos in non-load bearing concrete components.It is a new type of green environmental protection enhancing material which is widely used for the high performance enhanced concrete.

- Q: my boyfriend wants the jordan black cement 3's from 2011 do u know the price of them and where i can buy them ? thank uuu :)

- Probably the most common occurrence and issue out there is having gum stuck on your shoes. There are time when it comes right off, then there are times when it's a desperate struggle to remove every single sticky bit of it off your shoes. The Air Jordan 3 has had a big year with some much loved, classic colorways returning to NikeStore, as well as a new edition especially for this year. Launching on Black Friday is the next installment the iconic Black/Cement Air Jordan 3 Retro. With big-time innovation and lethal good looks, the Air Jordan 3 was the first shoe designed by Tinker Hatfield and features visible Nike Air and elephant print alongside the introduction of the iconic Jumpman logo. The launch of this shoe was the first time Spike and Mike hooked up and Mars Blackmon started hitting TV screens around the world.

- Q: will i get crutches from er if i hit my knee cap on the cement step and went to the er or walk in clinic please explain and what if i just go in hopping in on one leg do you think they would give me crutches. do they show you how to use them please explain i want to use crutches

- your stupid. crutches hurt ur under arms and you want to hurt yourself just to use them. go to a big as chemist and buy some.. and yeah your probably would need them, depending on how hard you hit it. your probly need to dislocate it or worse

- Q: 325 ordinary home improvement cement is not to 50 kg people to sell? Questions added: Also, fill the gap between the white cement, buy two or three kilograms, people will sell it? More

- Under normal circumstances, the cement is bought by bag. If you just want a little bit, find someone else to a little, will give, or to protect the helium 氦 send a large number of money. White cement, is on the buy ...

- Q: I have a walk-in shower (no door) and was planning on using cement board for the wall floor. Do i have to use a vapour barrier behind the cement board on the would frame? If so, what kind? Simply lay the tile on the board (wall floor) with thinset? What kind of thinset? Any help would be appreciated! Thx

- More info is needed. What is on the floor of the shower now? A vapor barrier is needed for and insulated exterior wall. I use 15lb felt but 6mm poly can be used also. Insulation-vapor barrier-cement board with edges and corners taped with cement board fiberglass tape and thinset. Versabond modified thinset.

- Q: please tell me which of them is toughest?And I would like to get to know some recipes for both of them in order to use them in my yard

- Cement is an ingredient in concrete, much like flour is an ingredient in cake mix. Dry, powdered (portland) cement is blended with sand, stone and water to produce concrete. Kuhlman Corporation is a producer of ready-mixed concrete. A cubic yard of concrete measures three feet by three feet by three feet, or 27 cubic feet. It will weigh about 4000 pounds. It will cover an area of 81 square feet when placed four inches thick anything you want really 4 to 1 is a good mix for brickwork but if you want a harder or stiffer mix then just add more cement or a little less sand but keep the mixes the same if your work is being exposed or you will end up with different colours

- Q: How long before i can dive on newly poored cement?

- You should never dive on cement. It hurts like a bastard.

- Q: could you please tell me a precise price for a square meter of cement.

- It depends on the thickness.... 4 Slab around $55.00: 4 Slab = around 550 pounds Cement Mix 10 cm Slab = around 250 kilos Cement Mix 6 Slab around $80.00: 6 Slab = around 800 pounds Cement Mix 15 cm Slab = around 360 kilos Cement Mix

- Q: Looking for ideas on pouring a cement bartop?

- This is one of the trickiest concrete pours (actually placement is the correct term). The long expanse and comfortable overhang makes it so. That being said you need to use some 1/4 steel plates directly on top of the bar to support the weight of the overhang. Can the bar itself support the weight of the cement in the first place? Make sure that the concrete totally covers the steel plate and edge. Use melamine for the forms and screws. Support the melamine form with 1x 3's from the underside of the forms to the floor. Find a friend, family member or friend of a friend who is familiar with concrete placement. Rent a mixer to aid in mixing the cement and use a clean rust free rebar. Assuming you're going to use a concrete stain once the cement cures chose a light colored stain to show of the concrete's texture. Buy some brass square stock approx 1/4x 1/4x 12 and layout them out to form a several rows to act as a draining grid for your bar ware and embed them in your concrete after its floated. Buy small frosted glass votive candle holders and embed them upside down randomly so that you can install an fluorescent light under the bar top and allow light to shine through the randomly placed votive candle glasses. Finally get a back issue of Fine Homebuilding magazine, their september 1999, No. 125 issue has an informative article on Poured-In-Place Concrete Countertops

- Q: please i need advantages and dissadvantages, like how carbide is more expensive, and how high speed steel is resharpable.also a website for references would be nice, thanx in advance.

- Generally, cemented carbide is harder than high speed steel. To last the longest and provide the best cuts It also requires different rake angles relative to the material being cut. A negative rake angle is better with cemented carbide cutting tools and a positive rake angle is better for high speed cutting tools. The material being machined is also a factor in the best rake angle.

- Q: is it possible to make my pvc cement quot;normalquot; again... because now its all dry...

- You would be better off to buy some new stuff, but there is a remote possibility you can make it glue again by mixing some acetone in to it, but, but , but the acetone is more expensive than buying new pvc cement. So the moral of this story is; buy new pvc cement and get used to the idea that the stuff will dry out with some regularity. Actually eventually it all dries out even if you are careful to close the can very tight. It is a universal truth in life. I wish I had $5.00 for every can of that stuff that has gotten hard on me.

1. Manufacturer Overview

| Location | Hubei,China |

| Year Established | 2005 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | Southern Europe 10% Northern Europe 10% Central America 10% Western Europe 10% Eastern Asia 10% Mid East 30% Africa 20% |

| Company Certifications | N/A |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai PORT |

| Export Percentage | |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English;Chinese; |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | |

| Product Price Range | 示范:High;Average |

Send your message to us

AR Glassfiber Spray Roving for Concrete

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 18MTS watt

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords