Concrete Lifting Eyes

Concrete Lifting Eyes Related Searches

Forming Concrete Concrete Resurfacing Translucent Concrete Concrete Shotcrete Spray Concrete Spray On Concrete Concrete Cap Blocks Concrete Slickline Waterproofing Concrete Floors Diy Concrete Countertops Fast Curing Concrete Additives Concrete Driveway Resurfacing Concrete Mixer Concrete Iron Rods Waterproof Concrete Blocks Steel Rods In Concrete A Frame Lifting Equipment Off Form Concrete Ready Mix Concrete Bags Crane Lifting Sealing Concrete Driveway Plasticiser For Concrete Concrete Repellent Form Work Concrete Concrete Mixing Machine Waterproofing Concrete Block Walls Concrete Driveway Concrete Siding Installation Goods Lift Concrete Driveway CoatingsConcrete Lifting Eyes Supplier & Manufacturer from China

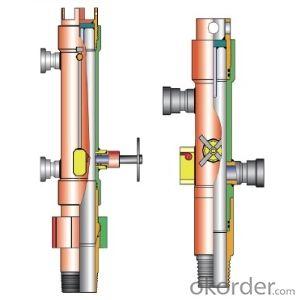

Concrete Lifting Eyes are specialized lifting devices designed to provide secure and stable support during the handling and transportation of concrete structures. These products are engineered to withstand the immense weight and pressure exerted by heavy concrete slabs, ensuring the safety of both the material and the personnel involved in the lifting process. The application of Concrete Lifting Eyes is vast, as they are commonly used in construction projects, civil engineering, and the transportation of precast concrete elements. They are essential in scenarios where precision and reliability are paramount, such as in the installation of concrete slabs for bridges, buildings, and other infrastructure.Okorder.com is a reputable wholesale supplier of Concrete Lifting Eyes, offering a comprehensive range of these essential lifting devices to cater to the diverse needs of the construction industry. With a large inventory that includes various sizes and designs of Concrete Lifting Eyes, Okorder.com ensures that customers can find the perfect fit for their specific lifting requirements. This extensive selection, combined with competitive pricing and reliable customer service, makes Okorder.com a go-to source for Concrete Lifting Eyes and other lifting solutions.

Hot Products