Reinforced Concrete Moulds for Panel Slab Beam

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Reinforced Concrete Moulds for Panel Slab Beam

1. Structure of Reinforced Concrete Moulds for Panel Slab Beam:

Reinforced Concrete Moulds for Panel Slab Beam works on the long-line table, using the high-strength low-relaxation steel strand as the guide, using the pushing work method to forming the concrete hollow-core slab. The slab have the advantages of smooth surface, high-density structure, capable of making construction slabs of 4.2m to 18m. The GLY series concrete hollow-core slab mainly used on the larger bay workshop, school, hospital, shopping mall, office building, bulk storage plant etc.

2. Main Features of Reinforced Concrete Moulds for Panel Slab Beam:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

3. Reinforced Concrete Moulds for Panel Slab Beam Images:

4. Reinforced Concrete Moulds for Panel Slab Beam Specification:

Type | Aperture & diameter | Number and diameter of wires | Max span | Total power | Productivity (m/min) | Max. Load (KN/m2) | Overall dimension (mm) | Weight (kg) |

GLY180-1200 | 11/ peach | 12/9.5or12.7 | 9 | 18.5 | 1.1-1.3 | 16.16 | 2900X1500x1200 | 3300 |

GLY200-1200 | 8 /peach | 10/9.5or12.7 | 10 | 22 | 1.1-1.3 | 13.22 | 3700X1550X1550 | 5300 |

GLY250-1200 | 8/ peach | 10/12.7 | 12.6 | 33 | 1.1-1.3 | 11.1 | 3700X1550X1500 | 6200 |

GLY300-1200 | 6 /peach | 8/12.7 | 15 | 40 | 1.1-1.3 | 10.83 | 3700X1550X1500 | 6900 |

GLY380-1200 | 8 /rhomb | 8/12.7 | 18 | 39.2 | 0.8-1.0 | 12.27 | 4600X1850X1600 | 7500 |

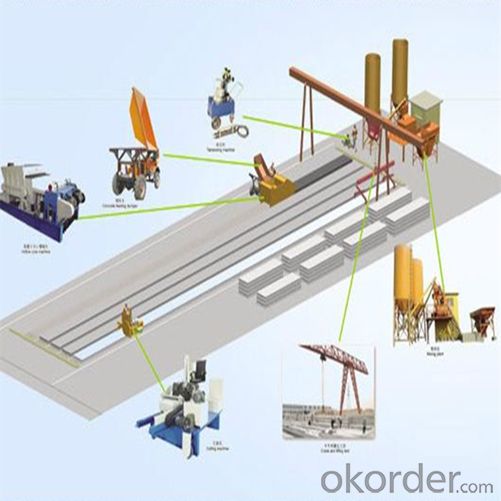

Production Layout

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

7. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

- Q: what is the quality of a central machinery 39743?

- MINI MULTIPURPOSE MACHINE , I'd guess you'll get what you pay for, i.e.. not much. I'd imaging that within it's limited capacity is might be an adequate (depending on ones requirements) lathe, but milling capacity will be quite limited.

- Q: I am making a hypothetical business for school and have decided to create a business that makes whey protein powder from the whey left over from the making cheese. I have searched all over the net but I cant find any information on the machinery used in this process. Can anyone help

- nope

- Q: maintenance for the 1st year is 150, and increases by 150 every year until the fourth year. if the interest is 85% per year find the equivalent uniform annual maintenance cost.

- Get a differnt credit card. 85% is way too high. . MWAP

- Q: can you give me the reviewer for electric machinery by fizgerald (5th ed) pls...?

- Magic Eight Ball says... “Yes - definitely.”

- Q: to other countries as another income stream. I already broker it in the USA. Is Exporting a good business?

- What type of machinery?

- Q: Do engineering technicians get to invent and patent ideas within large companies, or is this typically reserved for the mechanical engineers?

- Anyone can patent machinery. The question is, will a company be willing to pay a technician to spend his time inventing? Probably not. As a prior post indicated, the responsibility for solving the porblem, at least theoretically, usually belongs to the engineer. In good engineering teams, the problems are solved by more than one person. To that end if the idea is patented, everyone's contirbution should be documented. It usually comes down to a company's willingness to risk the cost of a patent on the potential payback. Fo that sort of risk assessment, they want to undertsand the magnitude of the gamble. Engineers are pretty good at detailing what the risks are and getting the approval for patents.

- Q: Material processing technology and machinery manufacturing What is the relationship

- Process: In the production process, where the direct change in the size of the object, shape, nature (physical properties, chemical properties, mechanical properties) and the relative position of the process, collectively referred to as the process. Such as rough manufacturing, machining, heat treatment, surface treatment and assembly, it is the main process of production, other processes known as the auxiliary process. Mechanical processing process: the mechanical processing methods, directly change the rough shape, size and surface quality, making it a product part of the process known as the mechanical processing process.

- Q: When a virus takes over the machinery of a cell, it forces the cell to manufacture:a. more mitochondria to provide energy for the virus b. more lysosomes for digestion c. more food particles d. more virus particles

- D. Look up the experiment done by Hershey and Chase. In their experiment, they used bacteriophages - viruses that attack bacteria.

- Q: Poll : Can you drive big machinery?

- The biggest I drove is a boat but only for a few minutes

- Q: Libraries in Chicago withcollections of trade catalogs. Chicago Machinery Exchange 1900-30?

- The Newberry Library (it's in the Gold coast) has many old items. They are very knowledgeable about this type of thing, they might know where to find it if they don't have it.

Send your message to us

Reinforced Concrete Moulds for Panel Slab Beam

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords