Vibration Concrete Purline Making Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Vibration Concrete Purline Making Machine

1. Structure of Vibration Concrete Purline Making Machine:

Vibration Concrete Purline Making Machine is our special developed products as results of our engineers research, with which 60%steel material will be saved compared with traditional revolving die method .Efficiency can be improved 3 to 5 times compared with conical die method, these machine are easy for operation and convenient for maintenance, products from these machines are in good quality, smooth appearance and accurate in size.

2. Main Features of Vibration Concrete Purline Making Machine:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

3. Vibration Concrete Purline Making Machine Images:

4. Vibration Concrete Purline Making Machine Specification:

Product name | Type | Productivity | Hole number |

Concrete purline machine | 60*120*140* | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*130*150*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*140*160*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 70*150*170*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 80*160*180*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 60*110*130*4 | 1.3-1.5m/min | 4 |

Model no. | No. of holes | Dia. | No. and dia. of wires | Electric motor power(kw) | Vibrator Motor Power(kw) | Total Power (kw) | Max. span | Molding Speed(m/min) | Overall dimension (mm) | Weight (kg) |

60X120X140X4 | 1 | 30 | 5/5 | 4 | 1.5 | 5.5 | 3.5 | 1.3-1.5 | 2250×900×850 | 1000 |

60X130X150X4 | 1 | 30 | 6/5 | 4 | 1.5 | 5.5 | 4 | 1.3-1.5 | 2250×900×850 | 1000 |

70X140X160X4 | 1 | 30 | 8/5 | 4 | 1.5 | 5.5 | 4.5 | 1.3-1.5 | 2250×900×850 | 1050 |

70X150X170X2 | 1 | 30 | 8/5 | 3 | 1.5 | 4.5 | 4.7 | 1.3-1.5 | 2250×900×850 | 750 |

60X110X130X4 | 1 | 30 | 6/5 | 4 | 1.5 | 5.5 | 3.5 | 1.3-1.5 | 2250×900×850 | 950 |

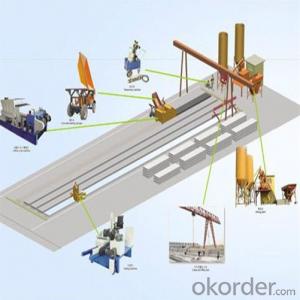

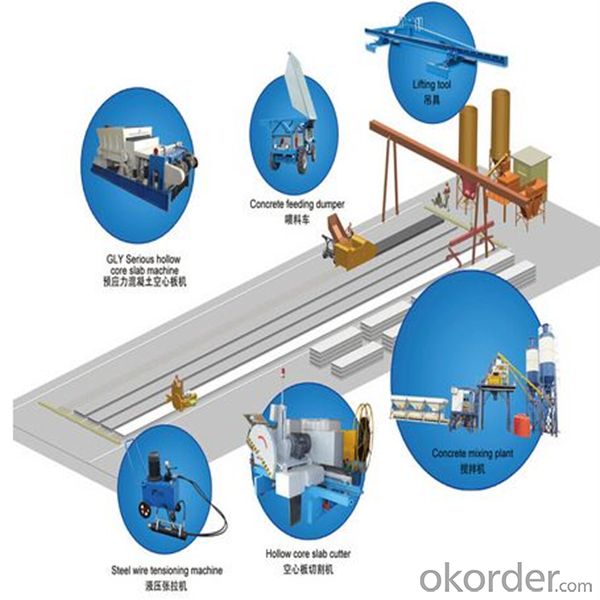

Production Line Layout

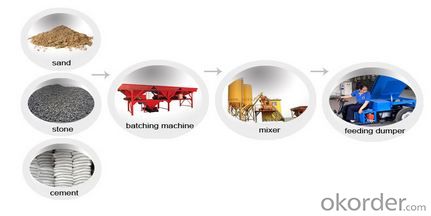

Production Process

Rebar tensioning

Raw materials preparing

Molding

Certificates

5. Customers from All Over The World

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

7. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

8. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply free quick wear parts.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q: I'm a vegetarian who doesn't eat fish and I was just wondering what this means.

- Here okorder /

- Q: why are men still allowed to operate weaponry and heavy machinery?

- Well, can you imagine Hilary Clinton as president and on her period and having access to nuclear weapons and dealing with a war crisis? Piss her off and she'll just push the button and goodbye Iran and North Korea. But then again, being that Hilary doesnt menstrate anymore, I think she would be able to handle her emotions better in these sort of situations. Male presidents, they'll just do it out of pride about having to prove their manhood like Bush did to iraq after 911 because everyone around him pressured his gullible dumb-azz. Thanks to him and Dick Cheney now we have economic issues. Bunch of irrational jerks.

- Q: Like Skynet from Terminator, there is a word they use besides quot;self aware.quot; A little help?

- Sentient?

- Q: whre can i download this book?...Electric Machinery Fundamentals (Power & Energy)By Stephen J. Chapman-4th edi?

- I'm okorder /

- Q: but the problem is that some materials are not available in india and i want to search the any material with same compositions of the requird materials. so is there any website or any book from where i can find that

- Matweb okorder

- Q: why are larger fields needed for machinery such as combine harvesters,tractors and ploughs?

- To have economy.

- Q: Metal materials commonly used in the processing methods which

- Extrusion, punching, reaming, upsetting, etc.) Die forging punching, bending, drawing, bulging, flaring, necking, flanging, etc. There are other special processing methods such as physical chemistry

- Q: What kind of material is used for processing shafts?

- When the working environment of the rotary shaft is relatively poor and the shaft has a large load, cantilever load and eccentric load, the shaft needs to keep a good fit with the fitting hole

- Q: what do companies benefit from when upgrading machinery?

- Depends what you mean by upgrading. A business can upgrade existing machinery to perform faster, better, etc or they can purchase a new machine to replace an older one. With upgrading the business is looking at increasing output, reducing operating costs and improving the efficiency of the machine. A new machine will potentially return less downtime due to breakdowns, but may have teething troubles whilst it settles in. New machinery will have costs involved, not only the purchase cost, but cost of spares, cost of training to operate and maintain, and depreciation. Hope this helps

- Q: When a virus takes over the machinery of a cell, it forces the cell to manufacture:a. more mitochondria to provide energy for the virus b. more lysosomes for digestion c. more food particles d. more virus particles

- D. Look up the experiment done by Hershey and Chase. In their experiment, they used bacteriophages - viruses that attack bacteria.

Send your message to us

Vibration Concrete Purline Making Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords