Vertical Concrete Purline Molding Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Vertical Concrete Purline Molding Machine

1. Structure of Vertical Concrete Purline Molding Machine:

Vertical Concrete Purline Molding Machine is our special developed products as results of our engineers research, with which 60%steel material will be saved compared with traditional revolving die method .Efficiency can be improved 3 to 5 times compared with conical die method, these machine are easy for operation and convenient for maintenance, products from these machines are in good quality, smooth appearance and accurate in size.

2. Main Features of Vertical Concrete Purline Molding Machine:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

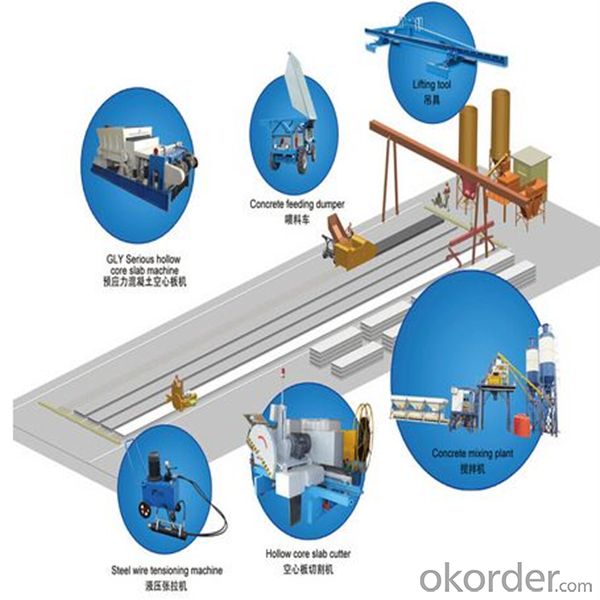

3. Vertical Concrete Purline Molding Machine Images:

4. Prefabricated Concrete Purline Compression Molding Machine Specification:

Product name | Type | Productivity | Hole number |

Concrete purline machine | 60*120*140* | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*130*150*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*140*160*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 70*150*170*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 80*160*180*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 60*110*130*4 | 1.3-1.5m/min | 4 |

Model no. | No. of holes | Dia. | No. and dia. of wires | Electric motor power(kw) | Vibrator Motor Power(kw) | Total Power (kw) | Max. span | Molding Speed(m/min) | Overall dimension (mm) | Weight (kg) |

60X120X140X4 | 1 | 30 | 5/5 | 4 | 1.5 | 5.5 | 3.5 | 1.3-1.5 | 2250×900×850 | 1000 |

60X130X150X4 | 1 | 30 | 6/5 | 4 | 1.5 | 5.5 | 4 | 1.3-1.5 | 2250×900×850 | 1000 |

70X140X160X4 | 1 | 30 | 8/5 | 4 | 1.5 | 5.5 | 4.5 | 1.3-1.5 | 2250×900×850 | 1050 |

70X150X170X2 | 1 | 30 | 8/5 | 3 | 1.5 | 4.5 | 4.7 | 1.3-1.5 | 2250×900×850 | 750 |

60X110X130X4 | 1 | 30 | 6/5 | 4 | 1.5 | 5.5 | 3.5 | 1.3-1.5 | 2250×900×850 | 950 |

Production Line Layout

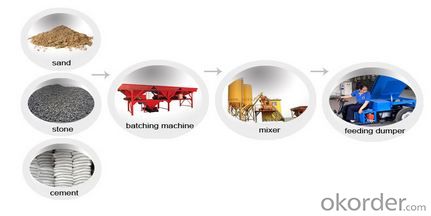

Production Process

Rebar tensioning

Raw materials preparing

Molding

Certificates

5. Customers from All Over The World

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

7. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

- Q: How does operating machinery under water complicate mining procedures?

- Absolute pressure at the surface is 14.7psi. Absolute pressure at 250 feet of see water for example is 126psi. That puts the machinery and people into a very different world that us surface dwellers from the get go. The BP job was at something like 7000 to 8000 feet if I remember correctly. That's about 3352psi. People can only dive to about 1000 feet of sea water. So on the BP job there were no people down there working. Everything we saw was from ROVs. Remotely Operated Vehicles. Doing things with a claw that is controlled by a joystick through a TV screen is very different from doing it with your own hands when you're right there looking at it. Even when you do have divers down there they usually only have 1 to 4 people. That's a limited team. They do not have a big box full of tools down there with them. They have the surface crew send the tools to them as needed. Salt water is not good for any kind of tool. It makes them rust and makes the seals break down. This leads to tool failure and many trips back and forth for replacements and repairs. The surface crew is usually young guys 18 to 25 who are not the most mature or reliable people in the world. Tool maintenance does not always get done properly. Divers are regular people. They are stubborn, arrogant, lazy, dumb and any other thing that you run into with coworkers anywhere. If they feel like sitting down for a break, the boss can't always keep a proper watch on them or come down and yell at them. We just finished a well abandonment job where we did the same thing with plugging a well with concrete just like the BP job and it took us 6 tries. That technique doesn't work too good at shallower depths either. This stuff is still full of bugs buts the pursuit of money keeps things moving beyond what we truly understand.

- Q: A. physicalB. intangibleC. tangibleD. transient

- i guess c

- Q: How to choose mechanical parts material ah?

- Different parts require different, and some require strong wear resistance, and some require high strength, and some requirements of the surface friction is small, the specific requirements for each part to find out, and then according to the material wear resistance, strength and other physical properties selected

- Q: describe the ways in which bacterial machinery can be utilized to replicate mammalian genome?

- NONE NON-EXISTENT WON'T

- Q: what rate of depreciation on new machineries purchase?

- The maximum section 179 deduction you can elect for property you placed in service in 2006 is increased to $108,000 for quali?fied section 179 property. This limit is reduced by the amount by which the cost of section 179 property placed in service during the tax year exceeds $430,000. Assuming you bought this equipment and it was placed into service in 2006, you dont have to capitalize it and depreciate it. You can elect to expense the equipment up to $108,000. This limitation gets reduced dollar for dollar for the amount of equipment placed into service in 2006 that exceeds $430,000.

- Q: In the novel, One Flew Over the Cuckoo's Nest, what does machinery stand for in Bromden's view?

- Machinery represents the accomplishments of man kind and what man kind is capable of doing.

- Q: I have a chance to get a machiery sales job (territory representative for heavy machinery equipoment sales).Since i had no much experience in this domain, i was hoping that somebody can give me tips (general tips) on how to do first sales calls and visits?How should i present myself and how to avoid sounding like telemarketer :)

- try craigs list

- Q: What kind of material is used for processing shafts?

- What material is to look at the specific situation, the general industrial machinery drive shaft is 45 steel, requiring a high point with 40 chromium, but also a good point with 42 chrome molybdenum.

- Q: i'm a Taiwan heavy industry and science instrument field agent. i hope i can use this website to contact factory owner to agent ther'e product.

- Best of Luck.

- Q: why on ship machinery's are installed forward-aft & not port starboard?

- Weight stability would be a primary factor.....You want the weight distributed along the center line

Send your message to us

Vertical Concrete Purline Molding Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords