Precast Concrete Purline Compression Molding Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Precast Concrete Purline Compression Molding Machine

1. Structure of Precast Concrete Purline Compression Molding Machine:

Precast Concrete Purline Compression Molding Machine is our special developed products as results of our engineers research, with which 60%steel material will be saved compared with traditional revolving die method .Efficiency can be improved 3 to 5 times compared with conical die method, these machine are easy for operation and convenient for maintenance, products from these machines are in good quality, smooth appearance and accurate in size.

2. Main Features of Precast Concrete Purline Compression Molding Machine:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

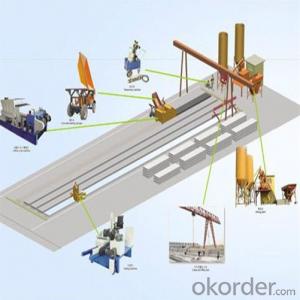

3. Precast Concrete Purline Compression Molding Machine Images:

4. Precast Concrete Purline Compression Molding Machine Specification:

Model no. | No. of holes | Dia. | No. and dia. of wires | Electric motor power(kw) | Vibrator Motor Power(kw) | Total Power (kw) | Max. span | Molding Speed(m/min) | Overall dimension (mm) | Weight (kg) |

60X120X140X4 | 1 | 30 | 5/5 | 4 | 1.5 | 5.5 | 3.5 | 1.3-1.5 | 2250×900×850 | 1000 |

60X130X150X4 | 1 | 30 | 6/5 | 4 | 1.5 | 5.5 | 4 | 1.3-1.5 | 2250×900×850 | 1000 |

70X140X160X4 | 1 | 30 | 8/5 | 4 | 1.5 | 5.5 | 4.5 | 1.3-1.5 | 2250×900×850 | 1050 |

70X150X170X2 | 1 | 30 | 8/5 | 3 | 1.5 | 4.5 | 4.7 | 1.3-1.5 | 2250×900×850 | 750 |

60X110X130X4 | 1 | 30 | 6/5 | 4 | 1.5 | 5.5 | 3.5 | 1.3-1.5 | 2250×900×850 | 950 |

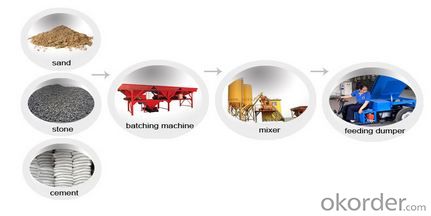

Production Process

Rebar tensioning

Raw materials preparing

Molding

Certificates

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. Customers from All Over The World

7. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

8. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

9. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply free quick wear parts.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q: It is related to the injection unit of molding machine

- Well, see this link.

- Q: I plan to dig a deep hole in Central Texas and the dirt is rather hard. I will be working alone. What hand tool would allow be to do this quickiest?

- a pick and shovel. if it is that hard soaking it with water will likely turn it back to clay, you will have a hard time working in it. my idea would still be hire a tractor with a post hole digger on it and make several holes at the same spot all the way around the area then shovel it out. depends on the size though you said big and in texas it must be really big then right? if so try a bull dozer then reseal where the dozer went into the pit, when done, you may die of exhaustion before finishing,otherwise

- Q: i need help w/ a science question lol....:] help please! thnx! o and also, the 1st question is more important, but if u know this one, it would help too: How is friction a factor in outer space?

- rather some what we do is actual extravagant and likely isn't activities we do interior the destiny as they are going to be called asinine and wasteful. i imagine such issues because the internet will make the great united states of america state out of date, if truth be told its out of date now, any united states of america more suitable than Portugal will probably split into smaller countries. there'll be extra decentralization and emphasis on close by-ness, and we would properly be placed lower back in our gardens for far of what we eat on a on a daily basis foundation, even severe tech indoor all 12 months gardens with tiny robotic pollinators, i imagine some English crew of chaps actual made robotic bees many years in the past. 3-d printers would made stuff out of superior biodegradable plastics derived from cotton or algae. and robotic prostitutes will cater to each and each of the deviants, and if truth be told each body. no longer advantageous what human beings will actual do, yet those issues would replace the way we artwork. there is resistance in this regard, although that is idea that folk would take care of to get a lot of what we deem college preparation from homestead, you may already pay interest to three lectures on podcast.

- Q: What type of machinery would you consider lawn mowers and weed 'whackers'?

- Could be defined as outdoor power equipment technically.

- Q: Who builds machinery to produce expanded metal ?

- google for it

- Q: Each part adds to the length of each item. There are 2 parts with a length of 3/4 inches, and 3 parts with a length of 1 5/8.What is the total length of machincery?a) 1 1/4 in b) 4 7/8 in c)5 1/8 in d)6 3/8in

- D

- Q: Details of Plant Machinery for Essential oil from medicines?

- Here okorder /

- Q: Reconditions will do, will need some for places with dire needs

- The okorder /

- Q: Poll : Can you drive big machinery?

- I have a forklift certification. I'm not in the operating engineers union though, so I don't attempt to use any of their equipment.

- Q: Hello, our family business is rather kind of in need, to start producing our cake mixes in larger quantities.I ahve not been able to find a manufacturer that sells this amchinery. Please ask any further questions.God Bless

- you okorder /

Send your message to us

Precast Concrete Purline Compression Molding Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords