Extruder Concrete Purline Making Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Extruder Concrete Purline Making Machine

1. Structure of Extruder Concrete Purline Making Machine:

Extruder Concrete Purline Making Machine is our special developed products as results of our engineers research, with which 60%steel material will be saved compared with traditional revolving die method .Efficiency can be improved 3 to 5 times compared with conical die method, these machine are easy for operation and convenient for maintenance, products from these machines are in good quality, smooth appearance and accurate in size.

2. Main Features of Extruder Concrete Purline Making Machine:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

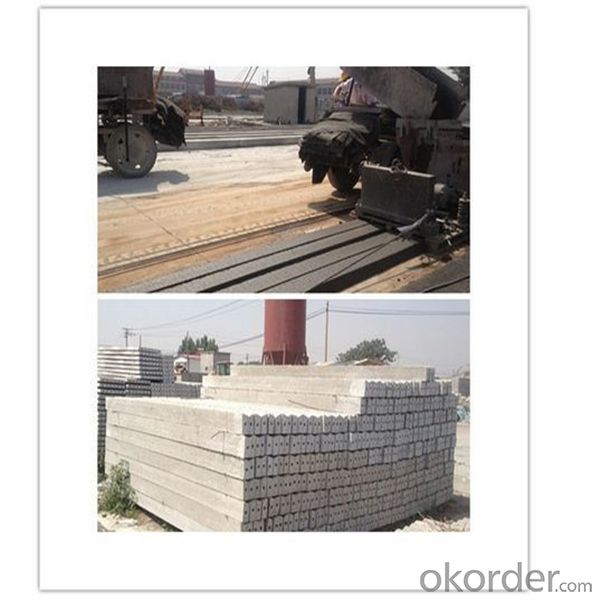

3. Extruder Concrete Purline Making Machine Images:

4. Extruder Concrete Purline Making Machine Specification:

Product name | Type | Productivity | Hole number |

Concrete purline machine | 60*120*140* | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*130*150*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*140*160*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 70*150*170*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 80*160*180*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 60*110*130*4 | 1.3-1.5m/min | 4 |

Model no. | No. of holes | Dia. | No. and dia. of wires | Electric motor power(kw) | Vibrator Motor Power(kw) | Total Power (kw) | Max. span | Molding Speed(m/min) | Overall dimension (mm) | Weight (kg) |

60X120X140X4 | 1 | 30 | 5/5 | 4 | 1.5 | 5.5 | 3.5 | 1.3-1.5 | 2250×900×850 | 1000 |

60X130X150X4 | 1 | 30 | 6/5 | 4 | 1.5 | 5.5 | 4 | 1.3-1.5 | 2250×900×850 | 1000 |

70X140X160X4 | 1 | 30 | 8/5 | 4 | 1.5 | 5.5 | 4.5 | 1.3-1.5 | 2250×900×850 | 1050 |

70X150X170X2 | 1 | 30 | 8/5 | 3 | 1.5 | 4.5 | 4.7 | 1.3-1.5 | 2250×900×850 | 750 |

60X110X130X4 | 1 | 30 | 6/5 | 4 | 1.5 | 5.5 | 3.5 | 1.3-1.5 | 2250×900×850 | 950 |

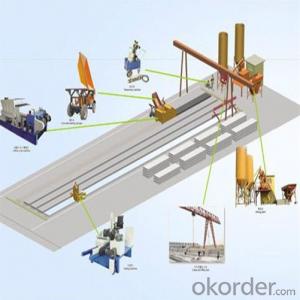

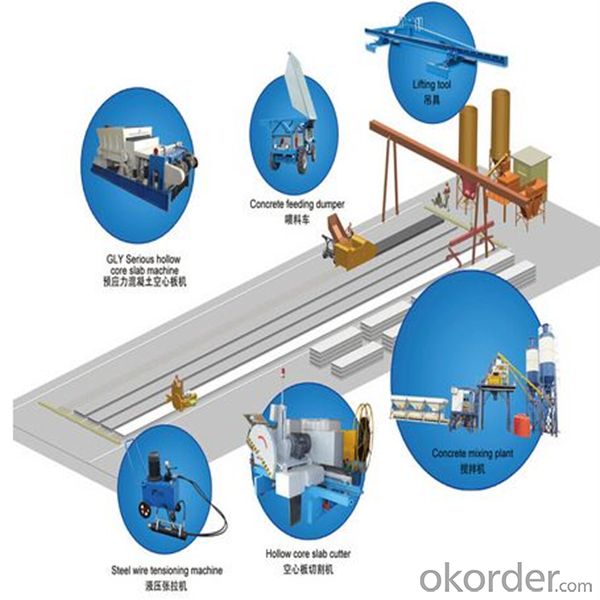

Production Line Layout

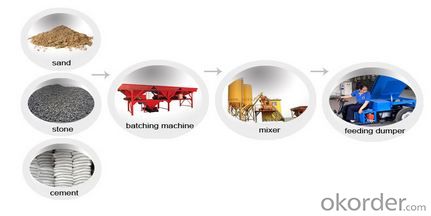

Production Process

Rebar tensioning

Raw materials preparing

Molding

Certificates

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. Customers from All Over The World

7. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

8. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply free quick wear parts.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q: Machinery was purchased for $51,000 on January 1, 2009. Freight charges amounted to $2,100 and there was a cost of $6,000 for building a foundation and installing the machinery. It is estimated that the machinery will have a $9,000 salvage value at the end of its 5-year useful life. What is the amount of accumulated depreciation at December 31, 2010, if the straight-line method of depreciation is used? $10,020. $8,580. $17,160. $20,040.

- $20,040: (51,000+2,100+6,000-9,000) / 5 = 10,020 per year 2009 - 10,020 2010 - 10,020 Total = $20,040

- Q: If the machinery that accomplishes X-chromosome dosage compensation in humans was defective (e.g., 1 protein was mutant), what do you expect the consequences would be? Choose one. a) no consequences b) XX embryos would not be viable c) XY embryos would not be viable d) both XX and XY embryos would not be viable

- B

- Q: Each part adds to the length of each item. There are 2 parts with a length of 3/4 inches, and 3 parts with a length of 1 5/8.What is the total length of machincery?a) 1 1/4 in b) 4 7/8 in c)5 1/8 in d)6 3/8in

- D

- Q: i am looking to go to school for machinery operating like cranes, hyax bull dozers that kind of stuffand i cant find anything in troy new york. I dont know hat i am doing wrong i just recently moved up her. Can anyone help me please? thank you

- Here okorder /

- Q: What is the processing of materials?

- The workability of the material means that the material exhibits excellent flow characteristics not only during injection molding but also excellent mechanical properties (strength, toughness and stiffness), short molding cycle (high productivity) and high temperature resistance (

- Q: Do engineering technicians get to invent and patent ideas within large companies, or is this typically reserved for the mechanical engineers?

- Anyone can patent machinery. The question is, will a company be willing to pay a technician to spend his time inventing? Probably not. As a prior post indicated, the responsibility for solving the porblem, at least theoretically, usually belongs to the engineer. In good engineering teams, the problems are solved by more than one person. To that end if the idea is patented, everyone's contirbution should be documented. It usually comes down to a company's willingness to risk the cost of a patent on the potential payback. Fo that sort of risk assessment, they want to undertsand the magnitude of the gamble. Engineers are pretty good at detailing what the risks are and getting the approval for patents.

- Q: what are working men and women who oporate machinery called?

- process workers

- Q: can you introduce me used or reconditioned agriculturally used machinery in usa.?

- There are dozens of equipment auctions all over the USA. Google Farm Equipment Auction and you should get many hits.

- Q: I have fat thighs but don't want to buy expensive machinery what do i do?

- run walk jumping jacks crunches push-ups with knees on the ground hop hop while sitting lift knees one by one duck walk

Send your message to us

Extruder Concrete Purline Making Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords