Prefab House Concrete Hollow Core Roof Slab Making Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prefab House Concrete Hollow Core Roof Slab Making Machine

1. Prefab House Concrete Hollow Core Roof Slab Making Machine:

The machine uses hydraulic lifting system, easy to revolve. It can reduce labor intensity and improve production efficiency. Machine body adopts anti-rust technology. Key parts, like hopper are welded by stainless steel. Wearing parts like reamers, side form, vibration board, stock guide and other parts are all welded with alloy. Both sides of the wall panels can put reinforcement wires, diameter can reach 6mm. Work area is orbital or no orbital.

According to the specialty of the local materials, we provide matching method to insure customer produce standard panels (general materials: fly ash, slag, ceramsite, cinders, cinerite, pumice, vermiculite and so on). Reduce the overall cost of building, increase indoor usable space.

High production efficiency, annual output square meters above 150000m.

2. Main Features of Prefab House Concrete Hollow Core Roof Slab Making Machine:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Simple structure, easy operate, less wear parts

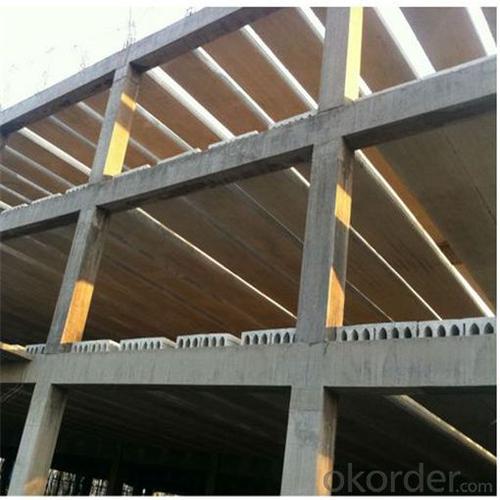

3. Prefab House Concrete Hollow Core Roof Slab Making Machine Images:

4. Prefab House Concrete Hollow Core Roof Slab Making Machine Specification:

Type | Aperture & diameter | Number and diameter of wires | Max span | Total power | Productivity (m/min) | Max. Load (KN/m2) | Overall dimension (mm) | Weight (kg) |

GLY180-1200 | 11/ peach | 12/9.5or12.7 | 9 | 18.5 | 1.1-1.3 | 16.16 | 2900X1500x1200 | 3300 |

GLY200-1200 | 8 /peach | 10/9.5or12.7 | 10 | 22 | 1.1-1.3 | 13.22 | 3700X1550X1550 | 5300 |

GLY250-1200 | 8/ peach | 10/12.7 | 12.6 | 33 | 1.1-1.3 | 11.1 | 3700X1550X1500 | 6200 |

GLY300-1200 | 6 /peach | 8/12.7 | 15 | 40 | 1.1-1.3 | 10.83 | 3700X1550X1500 | 6900 |

GLY380-1200 | 8 /rhomb | 8/12.7 | 18 | 39.2 | 0.8-1.0 | 12.27 | 4600X1850X1600 | 7500 |

Production Process

Rebar tensioning

Raw materials preparing

Molding

Our customers

5. Packing & Delivery

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

7. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q: Bq: have you read elfen liedBq2: favorite quote from a book

- Muscle Bound - Spandau Ballet. 2. I'm gonna hunt you down like a rabid dog! Hunter S. Thompson.

- Q: i need help w/ a science question lol....:] help please! thnx! o and also, the 1st question is more important, but if u know this one, it would help too: How is friction a factor in outer space?

- Motion is produced by some of the following: 1) rotating magnetic fields (electric motors) 2) explosions (internal combustion engine) 3) heat expansion of gas (steam engine, rockets) I am not sure about friction in outer space but I believe because there is no air or gases around joints and gears, friction would literally vacuum cement the sliding parts together. You would need to ensure that some sort of matter (gas, liquid) was present in order to allow parts to slide on top of each other.

- Q: Such as in terms of construction equipment like a crane, what is the maximum amount of weight that can be lifted by any existing machine?

- A crane's limitation is defined as metre-tonnes, because it is the moment that creates the limitation of the crane lift. A crane does the same amount of work to lift 50 tonnes at 10 metres as it does to lift 100 tonnes at 5 metres. That being said; I believe the largest single lift was perfromed by one of forty-two Lampson Tranis Lift IIs in Corpus Christi TX. The actual load was 1000 tonnes. And this just happens to be a MOBILE unit, on top of everything else!

- Q: I'm looking for a machinery for production of mini/small size plastic pots/jars for food (i.e. honey, butter, jam, melt cheese etc). To explain: You can remeber it from Your fligt-all this are provided in small plastic (sometimes glass) pots.

- Theres okorder /

- Q: Have you ever driven heavy machinery like a fork lift?

- I never have personally, but I work with people who drive them everyday. I work in manufacturing. There's a little tug machine I drive sometimes but its simple and more like driving a car than a forklift.

- Q: I know the basics - clear cut the trees, put explosives in the mountains, blow the mountain up, separate coal from waste, fill up valleys and then plant some grass. What I want to know if more about the machinery used - some sites talk about a quot;dragline,quot; but don't have any more info than quot;it is used in MTRquot; What kind of explosives are used? How do they gather/separate the coal from the mining waste?

- i might help combating it if the bobble head liberals might help one hundred new nuclear capability flowers be geared up interior the subsequent 15 years. Ever time you plug you clean, nonpolluting electric powered motor vehicle into your wall out permit the electricity comes from a coal or oil burning capability plant. The Al Gore devotees are no longer in basic terms hypocritical yet stupid!

- Q: Is there any difference between the two words? I want to name a company's name, the product is machines.By the way, what about packing and packaging? are the different. The machine is mainly packaging facilities, how can i name the company's name?

- Basically, a machine is a single item performing a function. Machinery is a group of parts or machines arranged to perform a function. Since that group of parts or machines can also itself be thought of as a machine, the terms are somewhat interchangeable... however most people will use machine to refer to the singular and machinery to refer to either it's inner workings (parts) or a collection of machines. Packing and packaging are similar, except that the first is usually used as a verb (to pack is the act of packing) and the second is used as a noun (referring to either the contents of a package or what the contents are packed into -- e.g., the box and wrappings). It is not clear what you mean by the machine is mainly packaging facilities, so not sure how to help you name the company... but I hope the above helps you do so.

- Q: What kind of material is used for processing shafts?

- When the working environment of the rotary shaft is relatively poor and the shaft has a large load, cantilever load and eccentric load, the shaft needs to keep a good fit with the fitting hole

- Q: plz help! its my homework :P ugh. thanks guys xD

- The Oxford American Writer's Thesaurus does not mention any antonyms. The opposite of a machine might be human labor. Did you mean synonym? (meaning similar) ... If so, apparatus ,hardware, gear, mechanism, gadgetry, tool, engine

- Q: Women: Do you like to operate machinery? Weedeaters? Lawnmowers? Tillers? Tractors? Etc?

- ive been blind my whole life thinking women were better then men cus thy were beautiful, they are nothing more then people to me know, and they should be lift to doing things that dont require too much physical strain, they will faint.

Send your message to us

Prefab House Concrete Hollow Core Roof Slab Making Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords