Presstressed Purline Beam Molding Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Presstressed Purline Beam Molding Machine

1. Structure of Presstressed Purline Beam Molding Machine:

Presstressed Purline Beam Molding Machine is our special developed products as results of our engineers research, with which 60%steel material will be saved compared with traditional revolving die method .Efficiency can be improved 3 to 5 times compared with conical die method, these machine are easy for operation and convenient for maintenance, products from these machines are in good quality, smooth appearance and accurate in size.

2. Main Features of Presstressed Purline Beam Molding Machine:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

3. Presstressed Purline Beam Molding Machine Images:

4. Presstressed Purline Beam Molding Machine Specification:

Product name | Type | Productivity | Hole number |

Concrete purline machine | 60*120*140* | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*130*150*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*140*160*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 70*150*170*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 80*160*180*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 60*110*130*4 | 1.3-1.5m/min | 4 |

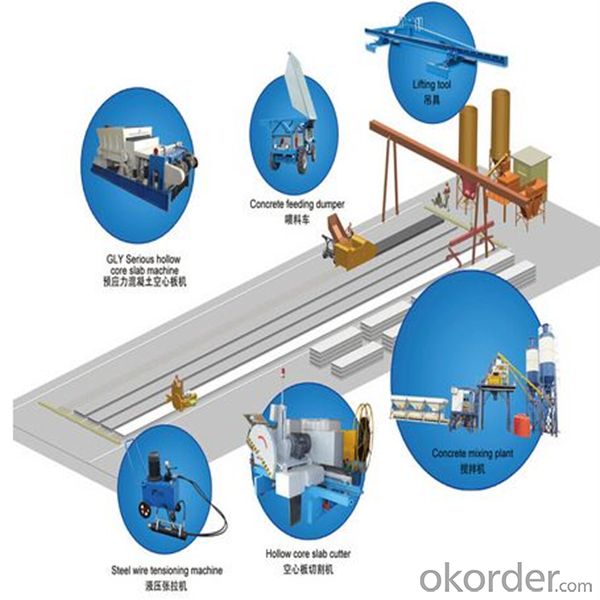

Production Line Layout

Production Flow Chart

Certificates

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. Customers from All Over The World

7. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the <Chinese Prestressed Concrete Hollow Core Slab Standard>.

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

8. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply free quick wear parts.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q: Jan. 1 Retired a piece of machinery that was purchased on January 1, 2001.The machine cost$62,000 on that date. It had a useful life of 10 years with no salvage value.June 30 Sold a computer that was purchased on January 1, 2008.The computer cost $40,000. Ithad a useful life of 5 years with no salvage value.The computer was sold for $14,000.Dec. 31 Discarded a delivery truck that was purchased on January 1, 2007. The truck cost$39,000. It was depreciated based on a 6-year useful life with a $3,000 salvage value.InstructionsJournalize all entries required on the above dates, including entries to update depreciation,where applicable, on assets disposed of. Ingles Company uses straight-line depreciation. (Assumedepreciation is up to date as of December 31, 2010.)

- You didn't state the year in which these transactions occurred. I'm assuming 2011. Jan. 1, 2011 Retired a piece of machinery that was purchased on January 1, 2001.The machine cost $62,000 on that date. It had a useful life of 10 years with no salvage value. Annual depreciation = $62,000/10 = $$6,200 By December 31, 2010, the machinery would be fully depreciated. Dr Accumulated depreciation $62,000 Cr Machinery $62,000 June 30, 2011 Sold a computer that was purchased on January 1, 2008.The computer cost $40,000. It had a useful life of 5 years with no salvage value.The computer was sold for $14,000. Annual depreciation = $40,000/5 = $8,000 By December 31, 2010, the accumulated depr account would have a balance of $24,000 (3 yrs) You need to depreciate another 6 mths to June 30, 2011 Dr Depreciation expense $4,000 Cr Accumulated depreciation $4,000 after which the accum. depr. would be $28,000, and the carrying amount $12,000. If it was sold for $14,000, there would be a gain of $2,000 Dr Accum depr $28,000 Dr Cash $14,000 Cr Computer $40,000 Cr Gain on disposal of computer $2,000 Dec. 31, 2011 Discarded a delivery truck that was purchased on January 1, 2007. The truck cost $39,000. It was depreciated based on a 6-year useful life with a $3,000 salvage value. Annual depr = ($39,000 - $3,000)/6 = $6,000 By December 31, 2010, the accum. depr. = $24,000 (4 yrs) You need to update depreciation by 1 yr Dr Depreciation $6,000 Cr Accum depr - Truck $6,000 after which the accum depr = $30,000, and the carrying amount = $9,000 Dr Accum depr $30,000 Dr Loss on scrapping of vehicle $9,000 Cr Vehicle $39,000

- Q: I am planning to setup a juice processing unit and therefore need help and info on the plant and machinery either on turnkey basis or upfront selling along with technology transfer.

- I okorder

- Q: Any web site could get free machinery manual?

- actually, okorder /... Cheers nb: please visit my web site

- Q: Have you ever driven heavy machinery like a fork lift?

- I never have personally, but I work with people who drive them everyday. I work in manufacturing. There's a little tug machine I drive sometimes but its simple and more like driving a car than a forklift.

- Q: I'm in 7th grade so please dont make this too difficult to understand.Thanks. :]

- try this site

- Q: What is the processing of materials?

- High temperature heat distortion temperature, high melting point).

- Q: to other countries as another income stream. I already broker it in the USA. Is Exporting a good business?

- it's the only buisness left unless you are moving in the service direction....export is global and we must go global with the rest of the world or stay content ,,,,,forward and upward is export.....

- Q: what are working men and women who oporate machinery called?

- process workers

- Q: I need a list of machinery, and the methods of how trees are cut down. Do they only use chainsaws? or are there bigger machines that cut faster and better? plz answer, im trying to create an accurate scene in a painting ( im in the planing stages).

- I'm okorder /

- Q: Poll : Can you drive big machinery?

- I have a forklift certification. I'm not in the operating engineers union though, so I don't attempt to use any of their equipment.

Send your message to us

Presstressed Purline Beam Molding Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords