Concrete Roof Brick Slab Making Machinery

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Concrete Roof Brick Slab Making Machinery

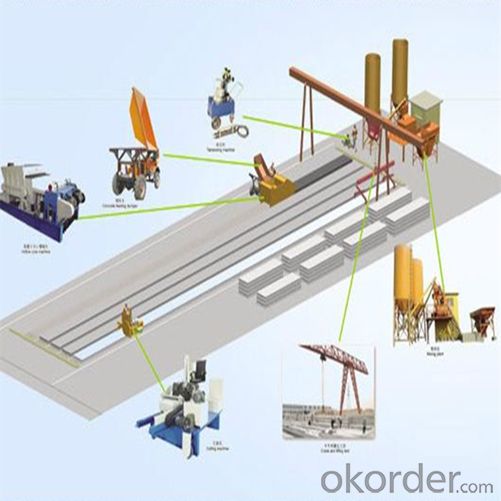

1. Structure of Concrete Roof Brick Slab Making Machinery:

Concrete Roof Brick Slab Making Machinery works on the long-line table, using the high-strength low-relaxation steel strand as the guide, using the pushing work method to forming the concrete hollow-core slab. The slab have the advantages of smooth surface, high-density structure, capable of making construction slabs of 4.2m to 18m. The GLY series concrete hollow-core slab mainly used on the larger bay workshop, school, hospital, shopping mall, office building, bulk storage plant etc.

2. Main Features of Concrete Roof Brick Slab Making Machinery:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

3. Concrete Roof Brick Slab Making Machinery Images:

4. Concrete Roof Brick Slab Making Machinery Specification:

Type | Aperture & diameter | Number and diameter of wires | Max span | Total power | Productivity (m/min) | Max. Load (KN/m2) | Overall dimension (mm) | Weight (kg) |

GLY180-1200 | 11/ peach | 12/9.5or12.7 | 9 | 18.5 | 1.1-1.3 | 16.16 | 2900X1500x1200 | 3300 |

GLY200-1200 | 8 /peach | 10/9.5or12.7 | 10 | 22 | 1.1-1.3 | 13.22 | 3700X1550X1550 | 5300 |

GLY250-1200 | 8/ peach | 10/12.7 | 12.6 | 33 | 1.1-1.3 | 11.1 | 3700X1550X1500 | 6200 |

GLY300-1200 | 6 /peach | 8/12.7 | 15 | 40 | 1.1-1.3 | 10.83 | 3700X1550X1500 | 6900 |

GLY380-1200 | 8 /rhomb | 8/12.7 | 18 | 39.2 | 0.8-1.0 | 12.27 | 4600X1850X1600 | 7500 |

Production Layout

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

7. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

- Q: I'm a vegetarian who doesn't eat fish and I was just wondering what this means.

- Here okorder /

- Q: i need help w/ a science question lol....:] help please! thnx! o and also, the 1st question is more important, but if u know this one, it would help too: How is friction a factor in outer space?

- Motion is produced by some of the following: 1) rotating magnetic fields (electric motors) 2) explosions (internal combustion engine) 3) heat expansion of gas (steam engine, rockets) I am not sure about friction in outer space but I believe because there is no air or gases around joints and gears, friction would literally vacuum cement the sliding parts together. You would need to ensure that some sort of matter (gas, liquid) was present in order to allow parts to slide on top of each other.

- Q: What is the best way to develop abs quickly without using any machinery?

- in case you elect to paintings specifically on abs, do sprints quite than long runs. the excellent ab exercising without kit is the bicycle the place you lay flat on the floor, and you deliver your knee approximately 0.5 thank you to your chest and touch it with your opposite elbow. the only nutrients advice i grants you is to consume 6 small nutrients, and get protein.

- Q: How to be the agent of zhengzhou Kefid machinery?

- kefid okorder

- Q: where can i get the list sugar plant machinery with the details & market value?

- Ask Dole Pineapple or look on the US Dept Us Agriculture website or google

- Q: but the problem is that some materials are not available in india and i want to search the any material with same compositions of the requird materials. so is there any website or any book from where i can find that

- Matweb okorder

- Q: i am setting up a condom factory in gujarat? where can i get the required machinery?

- Get in touch with the Head Office of Gujarat State Industrial Development Corporation, they would be in position to give you appropriate references. Alternatively approach CII, FICCI or ASSOCHEM, they have such manufacturers as their members.

- Q: green company purchased a piece of machinery on credit for 10,000.Briefly state how this transaction affect th?

- Green okorder

- Q: Hey, so I'm currently working on business coursework. We need to create a made up a business and i have chosen one of those businesses that print peoples picture on to items such a t-shirts, coasters mugs etc.. On one section i need to talk about the equipment and machinery i will need and to be honest i have no idea! could anybody give me a list of them?

- We are a company in heat transfer machine ,we can provide complete solution .you contact me on skype : c0400225

- Q: i want to buy from china

- through the service you just like engage a agent in China to help you to find what you need in China.

Send your message to us

Concrete Roof Brick Slab Making Machinery

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords