SP Concrete Prefab Slab making Machine for Roof

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SP Concrete Prefab Slab making Machine for Roof

1. Structure of SP Concrete Prefab Slab making Machine for Roof:

Products of this series (non-circular and circular cored) are the ideal machines for making building materials on constructions of large span and heavy load bearing in factories, schools, hospitals, shopping centers, office building and homes.

Our hollow core slab machines have the advantages of reasonable design, easy operation, convenient maintenance and long working life. Slab length can be achieved to 4.2m to 18m; width of 600mm, 900mm and 1200mm; thickness of 120mm, 150mm, 180mm, 200mm, 250mm, 300mm, 380mm.

The hollow core slab machines are working on the long-line table, tensioning the high-strength and low-relaxation steel strand first, and using the pushing work method to form the concrete hollow core slab. The slabs which being formed have the advantages of smooth surface and high-density structure.

2. Main Features of SP Concrete Prefab Slab making Machine for Roof:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

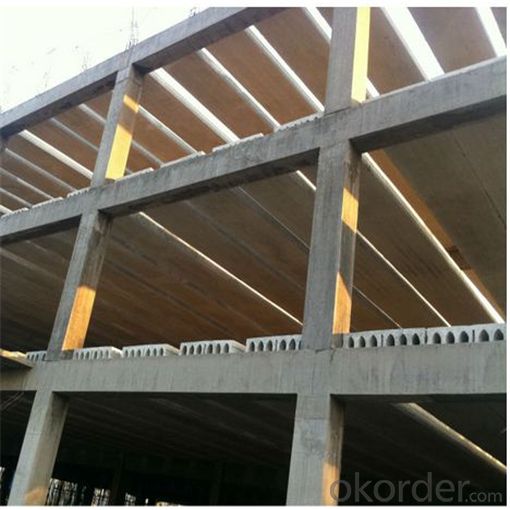

3. SP Concrete Prefab Slab making Machine for Roof Images:

4. SP Concrete Prefab Slab making Machine for Roof Specification:

Type | Aperture & diameter | Number and diameter of wires | Max span | Total power | Productivity (m/min) | Max. Load (KN/m2) | Overall dimension (mm) | Weight (kg) |

GLY180-1200 | 11/ peach | 12/9.5or12.7 | 9 | 18.5 | 1.1-1.3 | 16.16 | 2900X1500x1200 | 3300 |

GLY200-1200 | 8 /peach | 10/9.5or12.7 | 10 | 22 | 1.1-1.3 | 13.22 | 3700X1550X1550 | 5300 |

GLY250-1200 | 8/ peach | 10/12.7 | 12.6 | 33 | 1.1-1.3 | 11.1 | 3700X1550X1500 | 6200 |

GLY300-1200 | 6 /peach | 8/12.7 | 15 | 40 | 1.1-1.3 | 10.83 | 3700X1550X1500 | 6900 |

GLY380-1200 | 8 /rhomb | 8/12.7 | 18 | 39.2 | 0.8-1.0 | 12.27 | 4600X1850X1600 | 7500 |

Production Process

Rebar tensioning

Raw materials preparing

Molding

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

7. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

8. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply free quick wear parts.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q: It is related to the injection unit of molding machine

- Feed Screw Length to Diameter ration. It should be depends on different screw geometry and application.

- Q: I have to gain my wishes..People, somebody tell me. we were born, grew up, made choices (still making) and then society wants us to reproduce. Must everything be machinery?

- no... machinery makes life stop-uniform--steady--no ps no downs--just deadd.. so itf we wanna live keep the space to live.. make mistakes and cryy.. do some thing silly and laugh.. dont make everything a machine

- Q: Remember before the 1980s?When we had shop classes in our schools?When we actually made products in America?When we supplied the world with steel, machine tools, and automobiles?Remember when we had a working middle class?

- Yes . A farm tractor at the age of 8 . Had to run it standing up because if you sat down you couldn't reach the pedals .

- Q: Just to find out what it did. Or a good estimate?

- lol, buttons are supposed to be pushed or they wouldn't be there would they?

- Q: if not how much would you pay for one if i did it (NOT)

- If you did it, the chances of reliable accuracy would be small, no matter how good you are.

- Q: what are the machinery in which threads are used for power transmission?

- Ball screws and ACME screws are often used as the means to provide thrust in a linear actuator. Linear actuators are present in many, many applications.

- Q: I am going to be an interveiwer interveiwing either a Boatswain Mate or a Machinery Technician. I need links to websites with information about these types of people and their jobs because I need some information. Thank you.

- Boatswain okorder

- Q: Please introduce a link that explain these functions in a list or categorical. I would prefer new and interesting functions.Thank you

- Fluid okorder /

- Q: Like only 90 or 120 degrees, but it's precisely controlled.Thanks!

- The steering on your car.

- Q: What can I talk about in my agriculture machinery speech?

- Well...it wouldn't be popular, but it would be eye opening. You could talk about how the tractor companies took draft horses as down payment when they first started up decades ago. The draft horses were then sent off immediately for slaughter. In just a few short years, thanks the the coordinated work by the tractor companies the numbers of available draft horses plunged. That meant that farmers who were unhappy with their tractors, and wanted to go back to using draft horses (or draft mules) were unable to find any for love nor money. That was the beginning of the enslavement to debt of the U.S. farmer. Instead of running a horse that could reproduce itself, farmers now had to go into debt to buy tractors. It meant they worked longer hours (headlights on tractors) to pay for them. No longer did farmers work sun-up till sun-down. Agriculture quickly became a 24 hour a day job. Since the tractor didn't need time to rest, like a horse, it meant longer hours, and purchasing more land (more debt) for the farmer to pay for all the new tractors, and fertilizers that were being pushed on the farmers by agra business companies. Like I said, not a popular speech, but very factual, and something few people realize (even farmers). ~Garnet Permaculture homesteading/farming over 20 years

Send your message to us

SP Concrete Prefab Slab making Machine for Roof

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords