Aluminum Extrusion for Electric Power Engineering Sector

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Structure of Aluminum Extrusion for Electric Power Engineering Sector Description

Aluminum Extrusion for Electric Power Engineering Sector is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Aluminum Extrusion for Electric Power Engineering Sector

Aluminum Extrusion for Electric Power Engineering Sector | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Aluminum Extrusion for Electric Power Engineering Sector

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Aluminum Extrusion for Electric Power Engineering Sector

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Aluminum Extrusion for Electric Power Engineering Sector

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

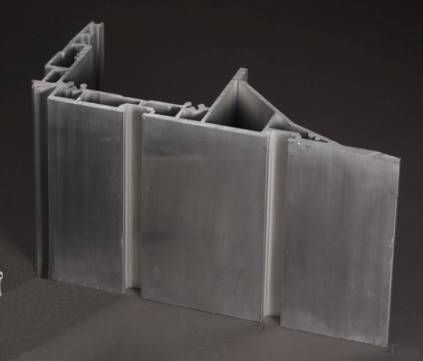

6. Image of Aluminum Extrusion for Electric Power Engineering Sector

7. Package and shipping of Aluminum Extrusion for Electric Power Engineering Sector

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:Can aluminum profiles be used for display cases or cabinets?

- Yes, aluminum profiles can be used for display cases or cabinets. Aluminum is a versatile and durable material that can be easily customized and fabricated into various shapes and sizes. It offers excellent strength-to-weight ratio, corrosion resistance, and a sleek modern appearance, making it a popular choice for display cases and cabinets in both commercial and residential settings.

- Q:What are the different shapes available in aluminum profiles?

- There are various shapes available in aluminum profiles, each designed to serve specific purposes and meet different structural requirements. Some common shapes include: 1. T-shape: This profile has a T-shaped cross-section, with a horizontal section and a vertical section. It is often used to create joints, connections, or support structures. 2. U-shape: This profile has a U-shaped cross-section, with two parallel sides and an open bottom. It is commonly used for framing, edging, or as a protective barrier. 3. L-shape: As the name suggests, this profile has an L-shaped cross-section, with one side longer than the other. It is frequently used for corner brackets, supports, or to create right-angle connections. 4. Square shape: These profiles have a square cross-section, with all sides equal in length. Square profiles are versatile and can be used for a wide range of applications, such as framing, rails, or supports. 5. Round shape: This profile has a circular cross-section, making it ideal for applications that require rounded edges or a seamless look. It is commonly used for handrails, decorative purposes, or in the automotive industry. 6. Rectangular shape: These profiles have a rectangular cross-section, with two longer sides and two shorter sides. They are often utilized for structural framing, supports, or as beams. 7. I-beam shape: Also known as an H-beam, this profile has an I-shaped cross-section with a central vertical web and two horizontal flanges. I-beams offer excellent strength and are commonly used in construction, bridges, or industrial applications. 8. Channel shape: This profile has a U-shaped cross-section with one side shorter than the other. It is widely used for structural support, framing, or as tracks for sliding doors and windows. These are just a few examples of the various shapes available in aluminum profiles. The choice of shape depends on the specific requirements of the project, such as load-bearing capacity, design aesthetics, or functionality.

- Q:Are aluminum profiles suitable for transportation equipment?

- Indeed, aluminum profiles are well-suited for transportation equipment. With its lightweight and durable nature, aluminum proves to be an excellent material choice, possessing a remarkable strength-to-weight ratio that makes it ideal for a wide range of transportation applications. Notably, it finds extensive use in the construction of aircraft, automobiles, trains, and ships. The advantages offered by aluminum profiles are numerous, including corrosion resistance, high thermal conductivity, and easy formability, enabling the creation of intricate and customized designs. Moreover, aluminum is environmentally friendly as it is recyclable, further enhancing its appeal as a sustainable option for transportation equipment. In summary, aluminum profiles excel in the transportation equipment field due to their lightweight nature, strength, versatility, and sustainability.

- Q:What is the opening section of aluminum profile?

- The opening position and the closed position are corresponding to the open section bar and the closed section section. Closed form refers to the outer contour of a profile forming a closed box shaped body; the opening is an outer contour without closure or no full closure. However, many practical profiles are more complex, with closed parts and open parts, which naturally produce "opening parts" and "closed parts"".The minimum column section thickness of the main stress parts, mainly referring to the national standard "Aluminum Alloy" building material GB/T5237 on the wall with a minimum thickness profile for 3.0mm, for the closed box section, with good resistance to local instability of the performance, can use a smaller wall thickness, the minimum wall thickness 2.5mm profiles, thus allowing.

- Q:Can aluminum profiles be an alternative to steel or other materials?

- Yes, aluminum profiles can be a viable alternative to steel or other materials in many applications. Aluminum profiles offer several advantages over steel, such as being lightweight, corrosion-resistant, and highly durable. One of the key benefits of aluminum profiles is their low weight. Aluminum is approximately one-third the weight of steel, making it an ideal choice when weight reduction is a priority. This lightweight nature makes aluminum profiles easier to handle, transport, and install, reducing overall costs and labor requirements. Additionally, aluminum profiles possess excellent corrosion resistance properties, especially when compared to steel. Aluminum naturally forms a protective oxide layer when exposed to air, which prevents further oxidation and corrosion. This makes aluminum profiles suitable for applications in industries such as construction, automotive, aerospace, and marine, where exposure to moisture, saltwater, or harsh weather conditions is common. Another advantage of aluminum profiles is their high strength-to-weight ratio. Aluminum alloys can be engineered to provide exceptional strength while still being lightweight. This makes them an excellent choice for structural applications where both strength and weight reduction are crucial. Furthermore, aluminum profiles are highly durable and can withstand extreme temperatures. Aluminum has a melting point of 660 degrees Celsius, significantly higher than most other non-ferrous metals. This makes it suitable for applications where exposure to high temperatures or thermal stress is expected. Aluminum profiles can also be easily fabricated, allowing for complex shapes and designs. They can be extruded, machined, welded, or formed into various configurations to meet specific requirements. This flexibility in manufacturing processes makes aluminum profiles a versatile material choice. However, it is important to note that aluminum profiles may not be suitable for all applications. Steel still offers superior strength and rigidity, making it more appropriate for heavy-duty applications or areas where high impact resistance is required. Additionally, aluminum profiles can be more expensive compared to steel, depending on the specific alloy and manufacturing processes involved. In conclusion, aluminum profiles can serve as a viable alternative to steel or other materials in many applications. Their lightweight nature, corrosion resistance, high strength-to-weight ratio, durability, and ease of fabrication make them an attractive choice for various industries. However, the specific requirements of each application should be carefully considered before deciding on the most suitable material.

- Q:Do aluminum profiles require any special tools or equipment for installation?

- Yes, aluminum profiles typically require specific tools and equipment for installation. These may include a miter saw or aluminum cutting saw, drill press or power drill, measuring tools, screwdrivers, clamps, and fasteners specific to aluminum profiles. Additionally, certain installations may require specialized equipment such as a router or end milling machine for precision cuts and shaping.

- Q:Household aluminum profiles, which brand of cost-effective? Recommend!

- Cost performance is better, in our Nanshan factory is called a good fight,

- Q:What is the aluminum section table?

- Table characteristics: working table, using aluminum material customized special products and durable, the breakage rate of the lowest! For quality of aluminum profiles, I strongly recommend item aluminum, aluminum fortunately which do not know, do not know how the quality of aluminum is our common problem. Here is a little experience for me to share with you.

- Q:Can aluminum profiles be used for staircases and handrails?

- Absolutely, staircases and handrails can definitely utilize aluminum profiles. Aluminum, being an incredibly versatile material, brings forth numerous advantages for these specific purposes. It boasts a lightweight nature, yet it possesses exceptional strength and durability, thereby rendering it ideal for bearing weight and ensuring stability in staircases and handrails. Moreover, aluminum exhibits resistance against corrosion, enabling it to withstand exposure to the prevalent moisture and humidity in these particular areas. Its adaptability facilitates the creation of a plethora of designs and finishes, making it a widely favored option for both contemporary and traditional styles. Furthermore, aluminum profiles offer effortless installation and maintenance, thereby presenting a pragmatic and cost-effective resolution for staircases and handrails.

- Q:How do aluminum profiles perform in electrical insulation applications?

- Aluminum profiles generally do not perform well in electrical insulation applications. Unlike materials such as plastic or rubber, aluminum is a conductor of electricity and does not possess the insulating properties required to prevent the flow of electric current. Therefore, using aluminum profiles in electrical insulation applications can pose significant risks, such as the risk of electric shock or short circuits. It is essential to choose materials specifically designed for electrical insulation purposes, such as insulating plastics or rubber, to ensure the safety and effectiveness of electrical systems.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Extrusion for Electric Power Engineering Sector

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords