AIR FILTER AR-2000 1"

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

pressure control pneumatic componentSMC AR4000-04

best solution for automation . strict quality and cost control system !

free to adjust the pressure range ,reduce the impurity of air .oil and water seperator .

best solution for automation . strict quality and cost control system !

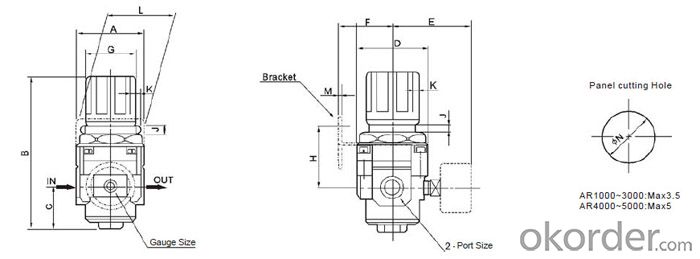

parameter diagram:

professional manufacturer of pneumatic ,best quality and severice for you !

- Q: What is the working principle of the five position valve of pneumatic components?

- Five position valve is usually a combination control valve, such as five position six way valve, control two actuators, such as pneumatic motor or cylinder. When the handle is in the 1 and 2 positions, an actuating mechanism is operated, and the other executing mechanism is operated at the 3 and the 4 positions. When the handle is loosened, the spring automatically turns the handle back to the middle stop position so as to realize the self-locking requirement.

- Q: How to maintain the pneumatic components regularly?

- The leak check should be done during the day, the workshop, the free time after work, or after work. At this time, the pneumatic device has stopped working, the noise in the workshop is small, but there is a certain amount of air pressure in the pipeline. According to the sound of leakage, we can see where there is leakage. Serious leakage must be dealt with immediately, such as hose rupture, serious loose at the junction. Other leaks should be recorded.

- Q: Pneumatic pressure regulating valve, two cups each have what function?.

- Next, the pressure reducing valve (pressure regulating valve) is used to stabilize the pressure by reducing the pressure drop through the compressed gas.Second cups: oil mist cup. Lubricating oil can be filled with 2/3 liquid level in it. The use of lubricating oil extraction of mixed oil mist cup compressed air spray mist gas together into the pneumatic pipeline system for pneumatic components of oil mist lubrication, the pneumatic components of sliding parts of smooth, durable.

- Q: How do pneumatic components sell well?

- Mainly can find support your manufacturer, can see the factory agent system, if loose and profit point is good, insist on doing it.

- Q: What are pneumatic triple parts?

- The function and sequence of pneumatic triple parts are:1. the oil and water filter filters out the water vapor, oil, gas and dust impurities from the compressed air, so as to purify the air.2. pressure reducing valve to reduce the pressure through the gas pressure, the stability of the work pressure.

- Q: Will the gas in the gas path corrode the pneumatic components after passing through the oil sprayer?

- The operating principle is that the atomizing oil is lubricated with high pressure air to the pneumatic equipment, and is not corrosive. Although the pneumatic solenoid valve or cylinder is no need to add lubrication. But friction products increase the service life by adding lubricating oil.Gas atomizer does not recommend adding common quality oil. It is recommended to use turbine No. 1 atomizer special oil.

- Q: I've checked PT teeth, NPT teeth and G teeth. I'd like to know which standard teeth we use on our cylinders, fast couplings and other components. Thank you

- The G is 55 degree tooth angle straight thread, and the NPT is 60 degree tooth angle, vertebral canal thread. What brands and cylinders do you use? What specifications do you want to see?.

- Q: What are the pneumatic components used in the industry?

- For example, I often see the pneumatic clamping, air hammer, pipeline transport and sorting,

- Q: Pneumatic components generally used in what industry?

- Such as cylinders, pneumatic motors, steam engines, etc.. Pneumatic components are a form of power transmission, as well as an energy conversion device that uses gas pressure to transmit energy.

- Q: Pneumatic components of SMC pneumatic components

- An element of a pneumatic element that does work by the pressure of the gas or by the force of its expansion is the component of the elastic energy of the compressed air that is converted to kinetic energy. Such as cylinders, pneumatic motors, steam engines, etc.. Pneumatic component is a kind of power transmission method. It is also an energy conversion device and uses gas pressure to transfer energy. 1. The layout of pneumatic equipment is simple and convenient, and the equipment protection is simple. Medium for air, compared to the hydraulic medium is not easy to burn, so the use of safety.2, the operating medium is inexhaustible air, the air itself does not cost money. The exhaust disposal is simple, without polluting the environment and low cost.3, the output power and operation speed adjustment is very simple. The speed of the cylinder is usually less than 1M/S, faster than the hydraulic and electrical methods of action.4, high reliability, long using life expectancy. The number of useful measures of electrical components is about a million times, and usually the solenoid valve life is greater than 30 million times, some good quality valves beyond 200 million times.

Send your message to us

AIR FILTER AR-2000 1"

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords