AIR FILTER BFR-2000 1/2

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

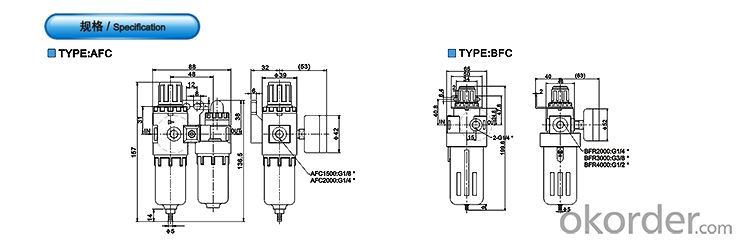

AFC\BFC Series

TYPE

small size

middle size

Joint pipe bore

1500:G1/8"

2000:G1/4"

3000:G3/8"

4000:G1/2"

Drian Type

Blank: Differential Drain

D: Automatic Drain

CERTIFICATE: ISO9001:2000 QEC CE

MAX PRESS: 9.9kg/c㎡

ADJ RANGE: 0.5-9.0kg/cm²

- Q: Which is good between pneumatic tools and power tools?

- 4. the pneumatic system has a strong adaptability to the environment. It can work reliably in a wide temperature range, humid and dusty environment, with a slight leakage, no pollution to the environment, no fire and explosion hazards, and safe use5., simple structure, convenient maintenance and low cost6. long life of pneumatic components7. pneumatic actuators of the hydraulic output than small, fast, strong adaptability, can exercise in the flammable, explosive, heavy, damp, the impact of the harsh environment, no environmental pollution, long service life, simple structure, easy maintenance, low price.

- Q: What is the difference between pneumatic components PC8-03 and PC8-02?

- Do you mean the connection? If it's the joint, 02 refers to PT1/4, and the 03 refers to the PT3/8, the joint is one side of the pipe and the thread, and the two are inserted into the 8 pipe

- Q: Graphical symbols for pneumatic componentsThis is a manual valve on the Oh!

- The median functions -1, 2, 3 and 4 are closed and are not communicated with each other;The bit function -1 through 2,4 through 3 (marked on the 3 pass 4 is obvious error)The actual professional mark is to use P, T, A, B, instead of the top 1, 3, 4, 2.

- Q: Pneumatic components generally used in what industry? What type of machine?

- An element that works by force of pressure or expansion of a gas, the component that converts the elastic energy of a compressed air into kinetic energy. Such as cylinders, pneumatic motors, steam engines, etc.. Pneumatic components are a form of power transmission, as well as an energy conversion device that uses gas pressure to transmit energy.

- Q: How to use the pneumatic components to control the automatic reciprocating movement of the cylinder (without electricity, mechanical touch control)?

- A crank motor connecting rod slider mechanism is driven by a pneumatic motor (a rotating cylinder). Or with a two-way pilot air control valve to design a loop to control the cylinder cycle. The two position five way two-way control valve and the cylinder block are connected into a whole, and the double headed cylinder rod is fixed and fixed, and the trigger positions of both sides of the valve are adjusted, and after the ventilation, the cylinder drives the reversing valve to move back and forth.

- Q: Main points of type selection of pneumatic control valve

- Pneumatic control valve refers to the pneumatic system to control the flow of air pressure, flow and flow direction, and to ensure that pneumatic actuators or institutions work properly all kinds of pneumatic components. Pneumatic control valve structure can be broken down into the valve body (including the valve seat and valve hole, etc.) and valve heart two parts, according to the relative location of the two, there are normally closed and normally open two. Valve from the structure can be divided into: cut-off type, slide column and slide valve type three valves.

- Q: Types of pneumatic Triplex Oil

- Now most of the cylinder, valve generally in the pneumatic components of the pre sliding parts parts into the semi-solid grease like (or paste oil) called non oil components. Therefore, there is no need to provide oil mist lubrication in such pneumatic transmission. If the oil mist lubrication to non oil pneumatic components, not only has no meaning, and semi solid lubricating grease is very thin oil mist and oil slowly dilute the sealed gas loss is bad. If the oil has been supplied with oil mist, it should remain the same.

- Q: What are the classifications of cylinders in pneumatic components?

- Classification of according to the structure characteristics of the cylinder1. piston cylinder. Including: ordinary single acting cylinder, double acting cylinder, double piston rod cylinder, cylinder, cylinder, differential number of tandem cylinder, an impact cylinder, Rodless cylinder, piston cylinder, magnetic stepping cylinder, supercharging cylinder, gas-liquid pressurized cylinder, oil damping cylinder, gear rack cylinder, cylinder, cylinder special cable.2. film type cylinder. It includes single acting film cylinder and double acting film cylinder.3. swing cylinder (or vane). There is a single leaf oscillating cylinder and two blade oscillating cylinder.

- Q: In turn, the pneumatic components follow the inlet direction. Why?

- Finally, according to the needs; is the oil mist by setting the lubricating oil mist cup extraction well mixed with compressed gas injection into mist gas, together into the pneumatic pipeline system for pneumatic components for lubrication. Therefore, the pneumatic components of these three functions must be carried out in this order.

- Q: Pneumatic valve, solenoid valve, pneumatic instrument work, air pressure in what range is appropriate?

- Pneumatic valve, solenoid valve, pneumatic instrument, air pressure in the 0.5Mpa~0.63Mpa (ie: 5~6.3kg/cm2) range is appropriate. Most of the work pressure on the use of pneumatic equipment in the industry is about 0.55Mpa. (i.e.: 5.5kg/cm2 or so). I hope I can help you.

Send your message to us

AIR FILTER BFR-2000 1/2

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords