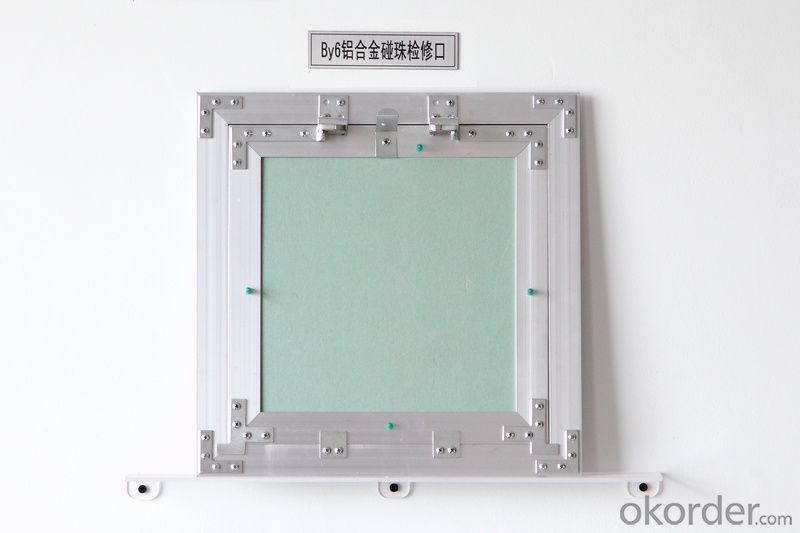

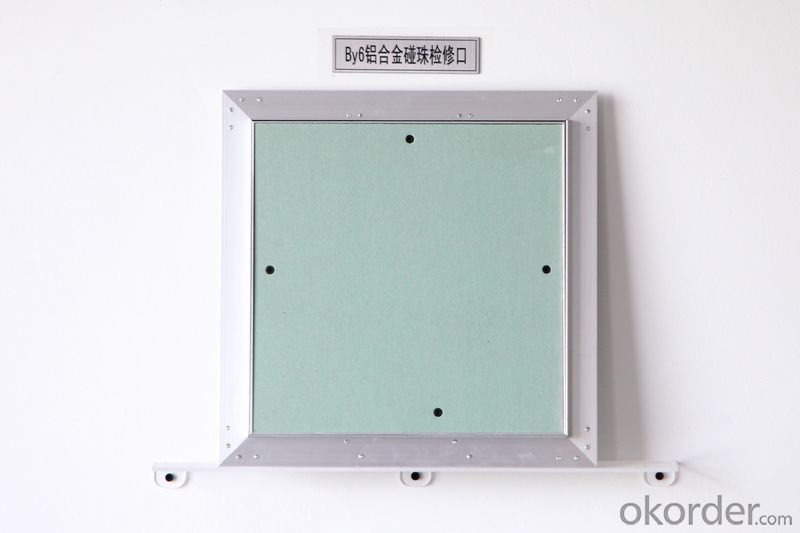

Access Panel Maintenance Aluminium Ceiling Trap Door

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Construction:

•Inner frame: High quality extruded aluminum alloy(A6063).

•Out frame: High quality extruded aluminum alloy(A6063)

•With gypsum board

Description:

•The frame are high quality extruded aluminum sheet construction with advantages of corrosion resistance and rigidity.

•It consists out frame and inner frame. The inner frame is fixed to the out-frame by hinges on one side and by screw on the other side..with elephant nose lock. With gypsum board

•The frame can be easily open to allow for maximum flexibility in the installation, maintenance.

Surface Finish:

•Powder coated color finish as per RAL color---- standard color: RAL9016

Character

Easy and quick installation

Continuous one-piece frame with feathered edge

High-class quality, perfect design, light weight but strong bearing capacity, no rusting and keeping forms.

Mildew resistant.

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 2 weeks after receiving of downpayment

Picture

- Q: Why the temporary building interior lime mortar plaster, a period of time after the wall generally cracked?

- The key is the material and the construction process, the sand is too thin or mud is too large, lime ripening is not good. Construction technology is not in place, mortar with the amount of lime is too large, plastering the wall before the end of the water is not uniform, plastering rubbing ram is not in place, lime cream when the surface is not uneven thickness, no second survival and so will cause cracking , So you have to analyze the reasons for the actual situation according to the scene.

- Q: My house is not yet in the house, but now in the decoration stage, but found the north of the bedroom windows (plastic windows) on both sides and both sides of the phenomenon of rainwater (rain 2 days or so there is water), developers have worked once but did not improve , Now looking for him to repair, but also an excuse for rainy day construction has been dragging, worried that I brush a good wall paint repair, affecting the decoration, so I want to repair their first solution. I do not know how to repair it? Thank you. : Figure more

- I see your picture, I see the external walls of water leakage, the windows are generally in the window below the water, your upper and sides, as well as the left side of the window so far, there are leaking, should be the wall leakage, I suggest you Buy waterproof treasure (liquid) on the outside brush 2 - 3 times, the window on the four sides made waterproof plastic, can only be the case

- Q: Do the doors and windows first do the inside and outside the wall plaster?

- Sure to do the inside and outside the wall plaster, and only plaster over, in order to determine the size of the window, so as to customize the doors and windows, do not forget to stay at the door when the retaining angle.

- Q: Sliding doors and windows to prevent shedding measures which

- (No less than two), no lower door of the door should be added nail horizontal pull to prevent the deformation in the transport and installation process; Second, the door window frame (the door frame) Or complete sets of doors and windows) should be designed according to the level of elevation and plane position in the process of building the wall; third, in the masonry wall installation of doors and windows (or sets of doors and windows), the nails should be fixed in the puzzle Bricks, each side of the fixed point should be no less than two, the spacing should not be greater than 1 2 m; Fourth, when the first wall after the installation of doors and windows (or sets of doors and windows), should be reserved in the door and window openings At the same time, leaving the door window frame (door and window frame, the lower end of the mouth at both ends of the mouth out of the gap) in the door frame adjustment in place after the closure gap. When the conditions are limited, the door frames can not stay in the head, should take reliable measures to the doors and windows frame fixed in the wall of wood bricks to prevent the construction or use of the process of security incidents; Fifth, when the door frame side of the need to set When the face plate, the door and window frame should protrude the wall, the protruding thickness should be equal to the thickness of the plaster layer, six, cold area door and window frame (or sets of doors and windows) and the gap between the external walls of the masonry, material.

- Q: What are the key points for the production and installation of wooden doors and windows?

- The production of good icu you and the size of the hole to the size of what accessories, i sealed ah! and many more

- Q: Plastic window is not also called plastic doors and windows, how to explain is a kind

- Is a kind of plastic doors and windows without pure meaning.

- Q: What is the horizontal line? How do I install windows and doors on a horizontal line?

- Horizontal line; in all rooms, the same height to find a horizontal line, before the use of horizontal tube to find points, and now with the level, infrared, when the doors and windows, doors and windows on both sides of the height parallel to the horizontal line, for example, 2 meters high door Down to the level of 1 meter, then both sides should have done 1 meter, which is the horizontal line installation

- Q: Do you have the order to install the floor and window? What order is it right?

- This is not the absolute order of the two, mainly to see their own preferences it

- Q: The first powder wall or the first door frame. What are the provisions? Or what is the reason for admiration. Questions added: the door is big and small. How to deal with. Whether the door frame is measured one by one. Uniform size will be a box does not match the problem. More

- First pink wall, after the door frame, and finally brush latex paint

- Q: Living in high-rise window how to install screens

- Two methods. The One is to get rid of the window. The Changed to open. The Then the shoes inside the window. The Another way is to install stealth Shachuang, installed on the outside of the kind. The

Send your message to us

Access Panel Maintenance Aluminium Ceiling Trap Door

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords