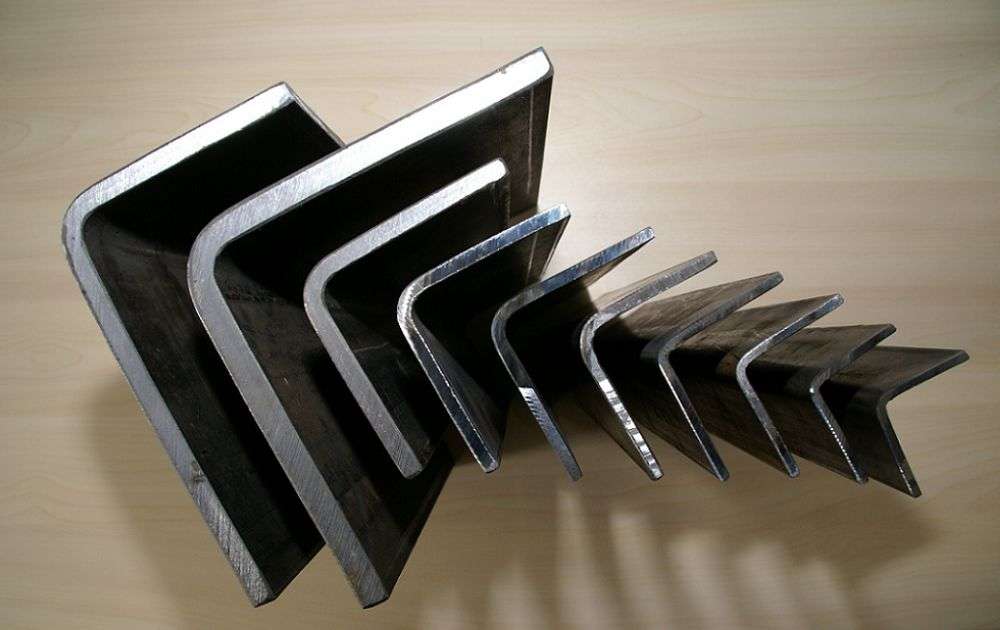

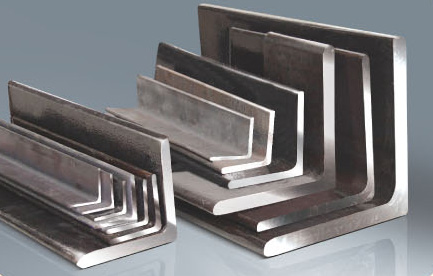

Angle Steel for Ship, Vessels and Other Steel Structures Building ASTM A276

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1)Standard:JIS AISI ASTM GB

2)Size: 25x25x3-100x100x10

3)Specification: as customers' requests.

Type | Stainless Steel Angle Bar |

Grade | AISI/SUS 201 202 301 302 303 304 304L 310 321 316 316L 410 420 430 |

Surface | Pickling, Sand Blasting |

Size | 25x25x3-100x100x10 |

Finished | Hot Rolled, Pickled, Sand Blasted |

Packing | Standard export packing, or as per customer's requests |

Payment | T/T, L/C, etc. |

Trade Terms | FOB/CFR/CIFetc. |

Stainless Steel Bar:

1.SS Angle Bar

*SS Equilateral Angle Bar

Specification:

Length: Standard length is 4m, 5m, 6m, length tolerance≤+ 40mm/pcs.

Shape: right angle tolerance is 2°

Surface: pickled or sand blasting.

2.SS Square Bar

*SS Cold Drawn Square Bar

*SS Hot Rolled & Pickled Square Bar

Specification:

Size: 12-180mm

Length:1-6mm

Surface: pickled&brushed

3.SS Hexagon Bar

*SS Cold Drawn Hexagon Bar

*SS Hot Rolled Hexagon Bar

Specification:

Diameter: 1.0-250mm

Length:1-6mm

Surface: bright

4.SS Flat Bar

*SS Hot Rolled & Pickled Flat Bar

*SS Drawn Flat Bar

Specification:

Thickness: from 3mm to 20mm

Width: from 19mm to 200mm

Length: 1-6Mm

Surface: pickled&brushed

OUR ADVANTAGES:

Our company is high quality supplier in China(mainland) with good reputation.

To develop the foreign markets, we provide customers high-quality stainless steel products with a competitive price, thoughtful after-sale service, excellent experience and import-export business skill.

Any questions, please feel free to contact with me!

- Q:How are steel angles used in construction?

- Steel angles are commonly used in construction to provide structural support and stability. They are often used as braces, struts, or beams to reinforce the framework of buildings, bridges, and other structures. Steel angles can also be used as corner supports, especially in the construction of walls and ceilings. Their versatility and strength make them an essential component in various construction applications.

- Q:What are the different types of steel angles connections for roof trusses?

- There are several types of steel angle connections commonly used for roof trusses, including gusset plate connections, bolted connections, welded connections, and clip angle connections. These connections are designed to provide stability and strength to the truss system, ensuring the overall integrity and safety of the roof structure.

- Q:What are the common applications of steel angles in architecture?

- Steel angles are commonly used in architecture for various applications such as providing structural support, creating framing systems, reinforcing corners and edges, forming lintels and beams, and supporting cladding materials. They are also used in the construction of staircases, handrails, and balustrades, as well as in the fabrication of window and door frames.

- Q:What is the maximum temperature that steel angles can withstand?

- The maximum temperature that steel angles can withstand depends on the grade of steel used. Generally, low carbon steel angles can withstand temperatures up to 600-700 degrees Celsius (1112-1292 degrees Fahrenheit) before their mechanical properties begin to deteriorate. However, higher carbon steels, stainless steels, or alloy steels can withstand higher temperatures, ranging from 800-1200 degrees Celsius (1472-2192 degrees Fahrenheit) or even higher. It is important to consult the specific material specifications or consult with a materials engineer to determine the maximum temperature a particular steel angle can withstand in a specific application.

- Q:What is the minimum thickness of a steel angle?

- The minimum thickness of a steel angle typically depends on the specific application and the structural requirements. However, it is generally recommended to have a minimum thickness of around 1/8 inch (3.175 mm) for standard steel angles.

- Q:How are steel angles welded or joined together?

- Different welding techniques are commonly employed to weld or join steel angles. The prevalent method involves the use of arc welding, which encompasses shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and flux-cored arc welding (FCAW). In shielded metal arc welding, an electric arc is established between a coated electrode and the steel angle. This causes the metals to melt and creates a weld joint. Gas metal arc welding, on the other hand, utilizes a continuous wire electrode and a shielding gas like argon or a combination of argon and carbon dioxide. This shielding gas safeguards the weld from atmospheric impurities. Flux-cored arc welding employs a hollow wire electrode containing flux. This generates a shielding gas and slag that protect the weld. Resistance welding is another technique used for joining steel angles. It involves the application of pressure and the passage of an electric current through the joint area. This generates heat, resulting in a weld. Spot welding and seam welding are commonly employed resistance welding methods for steel angles. Furthermore, steel angles can be joined using stud welding. This process entails placing a threaded or unthreaded stud against the steel angle and utilizing an arc welding process to fuse the stud to the angle. It should be noted that the choice of welding or joining method for steel angles depends on factors such as the thickness and type of steel, the desired joint strength, and the specific requirements of the application.

- Q:Can steel angles be used in equipment supports?

- Indeed, equipment supports can utilize steel angles. Owing to their robustness and adaptability, steel angles frequently find application in construction and structural contexts. They serve as dependable supports, braces, and reinforcements for diverse equipment and machinery. Given their capacity to withstand substantial loads, steel angles ensure stability and are thus well-suited for industrial equipment support. Moreover, their malleability and capacity for customization make them highly sought-after for equipment support due to their ability to satisfy specific requirements.

- Q:Can steel angles be used as supports for mechanical or HVAC ducts?

- Steel angles can indeed function as supports for mechanical or HVAC ducts. In the fields of construction and engineering, steel angles are popularly employed due to their ability to offer structural support and stability. These angles possess impressive strength and durability, allowing them to bear substantial loads while maintaining their shape over extended periods. By being installed correctly, steel angles effectively uphold the weight of mechanical or HVAC ducts, guaranteeing their stable positioning and preventing any sagging or collapsing. Moreover, steel angles can be conveniently customized and adjusted to suit specific duct sizes and configurations. On the whole, steel angles present a dependable and reasonably priced solution for supporting mechanical or HVAC ducts.

- Q:What are the common defects or issues found in steel angles?

- Some common defects or issues found in steel angles include surface imperfections such as cracks, scratches, or dents, dimensional variations such as uneven or inconsistent lengths, widths, or thicknesses, and improper alignment or straightness. Other issues can include corrosion, rusting, or lack of proper coating, as well as inadequate welding or joining, leading to weak or compromised structural integrity.

- Q:Are steel angles suitable for bridge construction?

- Yes, steel angles are suitable for bridge construction. They are commonly used as structural elements in bridge construction due to their strength, durability, and versatility. Steel angles offer excellent load-bearing capacity and can be easily fabricated and connected to form various bridge components such as trusses, beams, and girders. Their ability to withstand heavy loads and resist deformation makes them an ideal choice for bridge construction projects.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Angle Steel for Ship, Vessels and Other Steel Structures Building ASTM A276

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords