Steel Equal Angle

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Equal Angle

1. Standards: GB,ASTM,BS,AISI,DIN,JIS

2. Length:6m,9m,12m

3. Material: GB Q235B, Q345B or Equivalent; ASTM A36; EN 10025, S235JR, S355JR; JIS G3192, SS400; SS540.

4. Sizes:

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5. Chemical data: %

C | Mn | S | P | Si |

0.14-0.22 | 0.30-0.65 | ≤0.050 | ≤0.045 | ≤0.30 |

Usage & Applications of Equal Angle

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Products Advantages:

1. Convenient in construction and save much time and labor.

2. Light, good quality and reasonable price.

3. The shape and specification can be made by customer's requirement.

4. High mechanical strength.

5. Attractive in appearance and reasonable designs.

Packaging & Delivery of Equal Angle

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

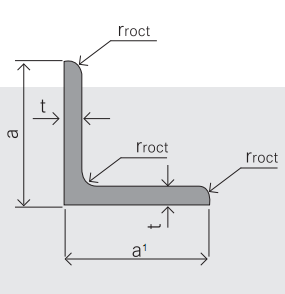

Images of Equal Angle

- Q:What is the difference between hot-rolled and cold-rolled steel angles?

- Two distinct methods, hot-rolling and cold-rolling, are employed in the production of steel angles, resulting in varying characteristics. Hot-rolling involves heating a steel billet or ingot to a high temperature and subsequently passing it through a series of rollers. This process allows for the metal to be shaped and formed while it retains its malleability and pliability. Consequently, hot-rolled steel angles possess a coarser surface finish and less precise dimensions when compared to their cold-rolled counterparts. However, their strength and durability are generally superior, rendering them appropriate for structural applications necessitating high strength and load-bearing capacity. Conversely, cold-rolling entails passing hot-rolled steel through a sequence of rollers at room temperature. This procedure not only refines the dimensions and surface finish of the steel angles but also enhances their strength and hardness. Cold-rolled angles exhibit a smoother surface finish and more accurate dimensions, making them ideal for applications requiring precise fitting or a polished appearance. They are commonly employed in architectural and decorative endeavors, as well as in industries where aesthetics and precision are paramount. To summarize, the primary disparities between hot-rolled and cold-rolled steel angles lie in their manufacturing processes, surface finishes, dimensional accuracy, and applications. Hot-rolled angles are stronger and rougher, rendering them suitable for structural purposes, whereas cold-rolled angles possess a smoother finish and precise dimensions, making them more appropriate for decorative and architectural applications.

- Q:What are the design considerations when using steel angles?

- When incorporating steel angles into design, there are several important factors to keep in mind. Firstly, the load-bearing capacity of the steel angles must be thoroughly evaluated. The anticipated loads and stresses that the structure will endure should dictate the selection of the appropriate size, thickness, and configuration of the angles. Another factor to consider is the structural integrity of the connections between the steel angles and other design elements. The connections must be designed to provide sufficient strength and stiffness, while also accommodating any potential movement or deformation of the angles. The potential for corrosion when using steel angles should also be taken into account. To prevent rust and deterioration, it is essential to apply suitable protective coatings or treatments, especially in outdoor or high-moisture environments. Aesthetics and visual appeal are also significant considerations in design. The shape, finish, and overall appearance of the steel angles should align with the desired aesthetic of the project, whether it is a modern, industrial look or a more traditional and ornamental design. Finally, cost and availability should be considered when incorporating steel angles. The project's overall budget should be weighed against the cost of materials, fabrication, and installation. Additionally, it is important to consider the availability of the desired sizes and configurations of steel angles to ensure a smooth and timely construction process. By carefully considering these design factors, designers can effectively integrate steel angles into their projects, guaranteeing structural integrity, aesthetic appeal, and cost-effectiveness.

- Q:Can steel angles be used in marine or coastal environments?

- Yes, steel angles can be used in marine or coastal environments. Steel angles, also known as angle irons, are commonly used in various construction projects, including those in marine or coastal environments. However, it is essential to choose the right type of steel angle with appropriate corrosion resistance properties to withstand the harsh conditions of saltwater, moisture, and constant exposure to sea spray. Stainless steel angles are an excellent choice for marine or coastal applications due to their superior corrosion resistance. Stainless steel contains chromium, which forms a protective oxide layer on its surface, preventing rust and corrosion. This makes stainless steel angles highly resistant to the corrosive effects of saltwater and moisture. Galvanized steel angles are another viable option for marine or coastal environments. Galvanization involves coating steel with a layer of zinc, which acts as a sacrificial barrier against corrosion. This protective zinc coating helps prevent the underlying steel from rusting and deteriorating in saltwater or high humidity conditions. It is crucial to ensure proper maintenance and care of steel angles in marine or coastal environments. Regular inspection, cleaning, and applying appropriate protective coatings can help extend the lifespan of steel angles and maintain their integrity against the corrosive elements. In summary, steel angles can indeed be used in marine or coastal environments. However, it is necessary to select the right type of steel angle with suitable corrosion resistance properties, such as stainless steel or galvanized steel, and maintain them properly to ensure their longevity and structural integrity.

- Q:What is the maximum cantilever length for a steel angle?

- Various factors, such as material strength, angle dimensions, and load requirements, influence the maximum cantilever length for a steel angle. Steel angles, commonly used as structural elements in construction, can be customized to accommodate different loads based on their size and configuration. In general, the ability of a steel angle to resist bending moments and deflection determines its maximum cantilever length. Bending moments occur when a load is applied to the free end of the cantilever, resulting in angle bending. Deflection refers to the degree of bending or sagging experienced under a specific load. Engineers rely on the moment of inertia, which measures the angle's resistance to bending, and the yield strength of the steel to establish the maximum cantilever length. The moment of inertia is impacted by the angle's dimensions, including flange width, flange thickness, and leg length. To ensure safety and compliance, it is crucial to adhere to project-specific design codes and standards. These guidelines outline the maximum allowable bending stress and deflection limits for steel angles under different loading conditions. To summarize, the maximum cantilever length for a steel angle is determined by factors such as material strength, dimensions, and load requirements. Calculation of the moment of inertia, consideration of yield strength, and compliance with relevant design codes and standards are essential steps in determining this length.

- Q:Can steel angles be used as structural supports for bridges?

- Yes, steel angles can be used as structural supports for bridges. Steel angles, also known as angle irons, are commonly used in bridge construction as they provide stability and strength. They can be used as diagonal bracing or as reinforcement for beams and columns, enhancing the structural integrity of the bridge.

- Q:Are steel angles resistant to termites and pests?

- No, steel angles are not susceptible to termite and pest infestations as they are made of inorganic materials.

- Q:What are the different design considerations for steel angles in architectural applications?

- When it comes to using steel angles in architectural applications, there are several design considerations that need to be taken into account. These considerations include the load-bearing capacity of the angles, their structural integrity, aesthetics, and overall design flexibility. One of the primary design considerations for steel angles in architectural applications is their load-bearing capacity. Steel angles are often used to provide structural support in buildings, so it is crucial to ensure that they can withstand the anticipated loads. This involves calculating the maximum load that the angles will need to bear and selecting angles with the appropriate size and thickness to handle these loads safely. Another important consideration is the structural integrity of the steel angles. Architects and engineers need to consider factors such as the angle's resistance to bending, buckling, and shear. The design should take into account the angle's ability to distribute the loads evenly, minimizing the risk of failure or deformation. Aesthetics also play a significant role in architectural design, and steel angles can contribute to the overall visual appeal of a building. Architects may choose to incorporate angles with different profiles, finishes, or decorative elements to enhance the design and create a visually appealing structure. The angles should complement the overall architectural style and blend seamlessly with other building materials. Design flexibility is another crucial consideration when using steel angles. Architects often require angles that can be easily customized or fabricated to meet their specific design requirements. Steel angles can be cut, welded, or bent to create unique shapes and angles, allowing for creative architectural solutions. Lastly, it's important to consider the material properties and corrosion resistance of the steel angles. Architects need to evaluate the environmental conditions of the project site and select angles that can withstand exposure to moisture, chemicals, or other corrosive agents. Proper coatings or treatments can be applied to protect the angles from corrosion and ensure their longevity. In conclusion, the design considerations for steel angles in architectural applications encompass load-bearing capacity, structural integrity, aesthetics, design flexibility, and corrosion resistance. By carefully considering these factors, architects can select steel angles that meet both the functional and visual requirements of their projects, resulting in safe, durable, and visually appealing architectural structures.

- Q:How are steel angles protected against impact or collision damage?

- Various methods can be utilized to safeguard steel angles against impact or collision damage. One effective approach involves strategically positioning protective barriers or bollards around the angles to absorb the impact and prevent direct contact. The choice of materials for these barriers, such as concrete, rubber, or steel, depends on the desired level of protection. An alternative method is to directly install impact-resistant guards or shields onto the steel angles. These guards are typically constructed from materials like polyethylene, rubber, or heavy-duty plastic, which possess the ability to absorb impact and minimize damage. For added protection, reinforcement elements like steel plates or bars can be incorporated into the guards. Moreover, steel angles can be coated or painted with impact-resistant coatings or paints. These specialized coatings are designed to effectively disperse and absorb the force of an impact, thereby reducing the likelihood of damage. Additionally, they provide an extra layer of defense against corrosion, further safeguarding the angles from deterioration caused by impact. Lastly, engineering and design considerations play a crucial role in protecting steel angles against impact damage. By thoroughly evaluating the structural requirements and potential risks, engineers can make informed decisions regarding appropriate dimensions, materials, and reinforcement techniques. Factors such as load-bearing capacity, impact force distribution, and structural integrity are carefully considered to enhance the angles' resistance to collision damage. In conclusion, the protection of steel angles from impact or collision damage entails a combination of physical barriers, guards, coatings, and thoughtful engineering. These measures aim to mitigate the risk of damage, prolong the lifespan of the angles, and ensure their structural integrity in a wide range of applications.

- Q:What is angle flower? Is it the same as angle iron?

- Welded steel pipe, welded pipe, welded steel pipe, is the same meaning, also called welded steel pipe, seamless steel tube is compared with the. Seamed tube is made of steel plates or strips welded together. Because of the different manufacturing process, it can be divided into longitudinal welded pipe and spiral welded pipe.

- Q:What are the different methods of impact testing for steel angles?

- There are several methods of impact testing that can be used to assess the toughness and resistance of steel angles. These methods include the Charpy V-notch test, the Izod test, and the drop weight test. 1. Charpy V-notch Test: This is one of the most commonly used methods for impact testing. In this test, a notched specimen of the steel angle is placed in a pendulum hammer. The hammer is released, swinging down and striking the specimen. The amount of energy absorbed by the specimen before it fractures is measured and used to determine the impact toughness of the material. 2. Izod Test: Similar to the Charpy V-notch test, the Izod test involves using a pendulum hammer to strike a notched specimen of the steel angle. However, in this test, the specimen is clamped vertically, while the hammer strikes it horizontally. The energy absorbed by the specimen is measured and used to evaluate its impact resistance. 3. Drop Weight Test: This method involves dropping a weight onto a specimen of the steel angle from a certain height. The specimen is usually supported on a solid base, and the impact energy is calculated based on the weight and the height of the drop. The deformation and fracture behavior of the specimen are then analyzed to determine its impact toughness. These different methods of impact testing help engineers and manufacturers assess the ability of steel angles to withstand sudden impact or shock loads. By evaluating the toughness and resistance of the material, these tests provide valuable information for designing structures and selecting appropriate materials for various applications.

1. Manufacturer Overview |

|

|---|---|

| Location | Tangshan, China |

| Year Established | 1996 |

| Annual Output Value | Above US$ 300 Million |

| Main Markets | Middle East; Korea; Southeast Aisa |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin; |

| Export Percentage | 70% - 80% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b)Factory Information | |

| Factory Size: | Above 900,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered; |

| Product Price Range | Average |

Send your message to us

Steel Equal Angle

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords