Borosilicate Float Glass 4.0 for Building Partition

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 kg

- Supply Capability:

- 100 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description:

Borosilicate glass, also known as high borosilicate glass, is known as the "King of Glass".

Its main component is about 80% silicon oxide and about 10% boron oxide.

At this time, both silicon oxide and boron oxide can basically form microtetrahedrons.

Framework (the more the micro tetrahedral framework in the glass is, the greater the ionic bond force will become, contributing to a more stable performance), the other is about 5% of stable oxide and about 5% of flux.

2. Main Features:

3. Advantage:

Float Glass is superior in quality when compared to other flat glass and has the unique characteristics of excellent surface finishing, flatness, uniform thickness, high optical quality and bright appearance.

The float process was invented in 1952.

Float technology has rapidly replaced plate and sheet facilities worldwide in recent decades.

Float glass derives its name from the float process used where the molten glass floats on the top of molten tin.

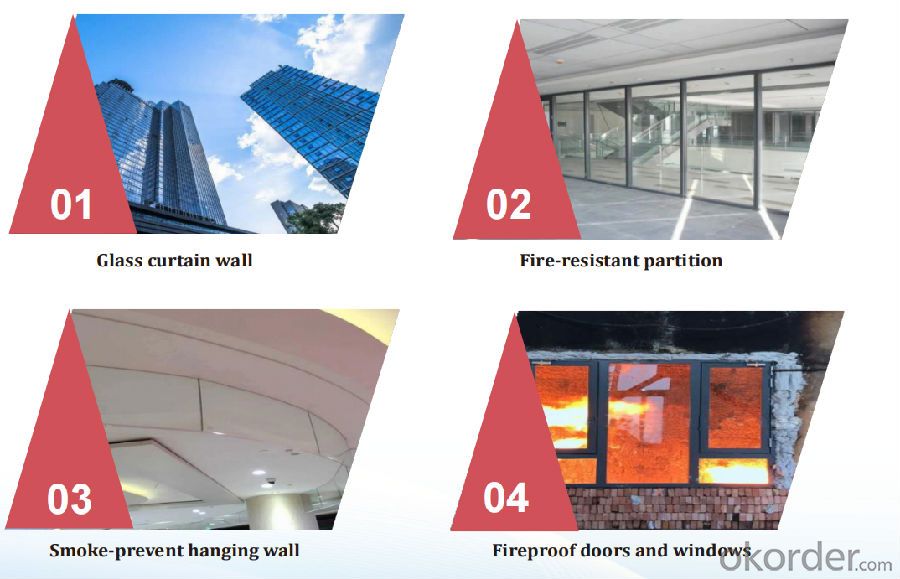

4 . Application Area:

Can be used in fireproof curtain walls, partition walls, platforms, day lighting roofs, smoke-proof vertical walls, railings, doors and windows, elevator shafts, rail transit platform screen doors, rail locomotive doors and windows and other fields.

Equipped with water spray, it can be used to replace Class A insulation type fireproof glass system, which can be widely used in building atrium, pedestrian street fireproof glass and building fireproof partition.

5. Company Brief:

6. Packing & Shipping:

All the glass will pack in strong export plywood crates, and load in container strong firmly, to make sure safety delivery.

- Q:Use of glass flake cement

- Coatings containing glass flakes are much harder than epoxy or polyester resin without glass flakes, and therefore have higher surface abrasion resistance.

- Q:What are the chemicals in glass?

- Common raw materials are quartz sand, feldspar, calcite, calcium carbonate, three, two aluminum oxide, sodium carbonate, borax and so on.

- Q:What are the construction principles and raw materials of tempered glass?

- Any of the above factors are closely related to the heating and cooling conditions of glass. When the glass is uniformly heated to the tempering temperature, it suddenly cools down. Because of the different cooling rate of the inner and outer layers, the surface layer cools and contracts rapidly, while the inner layer cools and contracts slowly. As a result, the inner layer is subjected to compressive compressive stress and the surface layer is subjected to tensile stress. As the glass continues to cool, the surface has hardened and stopped shrinking, while the inner layer is still cooled and contracted until the room temperature is reached. In this way, the surface layer is compressed by the compression of the inner layer, and the inner layer forms tensile stress and is permanently retained in the tempered glass. Because the glass is strong and weak tensile compressive brittle material, when the glass is broken more than tensile strength, so the size and distribution form of stress is the main factor influencing the strength of glass and crack. In another case, when the glass is cooled in a plastic state, whether it is uneven heating or uneven cooling, as long as there is a temperature difference on the same piece of glass, there will be different shrinkage. At room temperature, the higher the temperature, the greater the cooling, and the greater the shrinkage, the shorter the glass. On the contrary, the lower the temperature is, the less the cooling, the smaller the shrinkage, and the longer the glass. If a piece of glass is short of each piece, the board must be warped. In this way, it is not difficult to understand why glass is deformed and how to prevent deformation.

- Q:Is glass fiber reinforced plastic board fireproof partition board?

- The fire board also called Naihuoban, is based on the pressure in the wood with fireproof veneer made of fireproof performance, sound insulation effect, which belongs to refractory materials, widely used in interior decoration, furniture, kitchen cabinets, laboratory table, wall. General thickness of 17mm and 19 mm two kinds of thickness.

- Q:What's good with a cup?

- Is crisp or more toughness (generally good, there is a certain toughness), that is, to see whether it will be smashed at once, this kind of cup can not be.

- Q:What's the raw material for goldfish bowl?

- Look + trend: ordinary glass, ultra white glass, float glass, acrylicApplication: ceramic containers

- Q:The difference between crystal glass and glass

- Feel: the same volume of crystal glass and ordinary glass weight is not the same. High crystal glass will make you feel calm, heavy feel. Similarly, the lower the crystal glass, the lighter it will be. Ordinary glass weight is more self-evident.

- Q:How to distinguish between good and bad glass fiber reinforced plastic?

- Glass steel will be exposed his true strength in the actual use of the process, the quality of glass steel after a few years of use color slightly dim, the whole board intact, no obvious damage, glass steel it would withstand the test of practice, after a few years of use will appear corrosion fracture pores and other obvious damage the board is not so smooth, the color degradation is serious, the overall aging, general glass steel is to be used for twenty years, but two years later will appear glass steel inferior overall aging phenomenon, thus causing great losses to customers.

- Q:What is the glass industry?

- To process liquid glass into desired shapes, such as flat plates, various vessels, etc.

- Q:Long plastic soft glass is a food grade raw materials?

- The normal use of the family (including the dining table) is entirely without question

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Borosilicate Float Glass 4.0 for Building Partition

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 kg

- Supply Capability:

- 100 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products