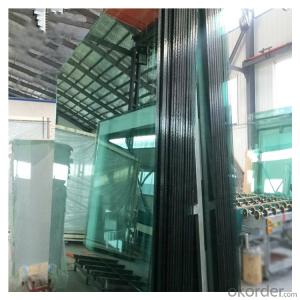

Safety Clear Tempered Laminated Glass Factory Price For stairs/floor/balustrade Glass

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Laminated Glass

Laminated glass is composed of two or more pieces of glass, sandwiched between a layer or multiple layers of organic polymer intermediate film, through special high temperature precompression (or vacuum) and high temperature and high pressure process, so that the glass and intermediate film permanent bonding as one of the composite glass products.

Specification

Single Layer Glass Thickness: 3-25mm

Max. Size: 3000*16000mm

Min Size: 100x300mm Interlayer: PVB, SGP, EVA, Sefar, Decoration Film, mesh etc.

Character:

A glass floor is a stunning, dramatic addition to any interior space. Not only does our glass flooring offer aesthetic appeal, but it also allows for light to flow into the space below. The unique benefits of CNBM glass flooring continue with its superior, rigorously tested framing system and its exceptional engineering support and design flexibility. With a beauty and simplicity that can’t be matched, Glass Flooring Systems’ interior system is the perfect solution for any glass-flooring project.

Our triple-laminated glass assembly is engineered for passive redundancy with panels that are fabricated using three layers of low-iron, tempered glass with structural PVB, SGP interlayers. Our structural glass delivers exceptional safety and design flexibility, with the top layer consisting of a safe, non-slip surface that allows light to filter into the space below. This layer can also serve as a form of artistic expression, with dozens of patterns, textures, and finishes that meet or exceed the ASTM safety standards. The role of the interlayers is to bond the layers of glass together to assure the safety and structural integrity of every glass flooring system we produce.

Advantage:

Our glass-flooring system comes standard with a variety of innovative features and options that give it distinct advantages over its competitors:Low-iron glass is standard with all our glass-flooring products;If you need, we can also provide proprietary 6063-T6 aluminum extrusions that produce crisp, clean profiles;Fully tested, anti-slip textures;Pre-engineered and custom sizes for ease of integration;

Packing and Shipping:

- Q:What kind of raw materials should be used in making FRP?

- Synthetic resin is a kind of synthetic molecules by a large amount of polymer, usually called polymer, also known as synthetic resin in polymer. The performance after heating is different, can be divided into thermosetting resin and thermoplastic resin two categories.Thermosetting resin refers to the heat or curing agent (including initiator) under the action of crosslinks and become insoluble and infusible solid state of a kind of resin, such as epoxy resin, phenolic resin, unsaturated polyester resin, furan resin. This resin can not soften cured after heating. High temperature decomposition and destruction.

- Q:Toughened glass and ordinary glass, process and raw materials what is the difference, a little more detailed, thank you

- Glass production process is: raw material crushing, screening, weighing, mixing, high temperature (1600 degrees) melting into glass, glass homogenization, cooling molding, cutting, annealing, cooling, inspection, packaging.The main raw materials are: quartz sand or sandstone, feldspar, soda ash, limestone, dolomite, etc., in addition to soda ash are ore raw materials, need to be broken into the appropriate size.

- Q:The practice of acid corrosion in tank

- Excellent technical performance, it can meet the corrosion protection requirements in the corrosive environment. Technical indexes are formulated for different coating varieties and matching. Such as chemical resistance medium, salt water resistance, salt fog resistance, heat and humidity resistance, oil resistance, mildew resistance, atmospheric aging, etc.. In addition, heavy duty coating has good adhesion to metal substrate. The coating has good physical and mechanical properties, such as low shrinkage, proper hardness, toughness, wear resistance and temperature resistance.

- Q:What material is the simulation tree made of?

- The earliest to do simulation trees, rockery are used cement, the recent simulation tree and rockery, with a lot of resin. First, the resin simulation degree is extremely high, two is the cost and the cement cost approximately.

- Q:Tile selection, paving process

- Clean up the grass ground, cement mortar, fixed elevation, elastic line, sheet materials choosing, soaking wet, standard for the installation of block, paving cement mortar, paving stone, pouring and cleaning, maintenance and commissioning.

- Q:What happens when toughened glass breaks?

- It blew the concept of rate, the national standard of our country only glass project on the wall, I do not know whether the other foreign industry to use the toughened glass also has detailed provisions.

- Q:Is the balance pad the raw material in the motor?

- Its main function is the use of mechanical energy into electrical energy, the most common is the use of thermal energy, water power, and so on to promote the generator rotor to generate electricity.

- Q:What is the raw material of glass?.

- 1. the main raw material of glass(1): the main component of silica sand or borax borax glass is introduced into silica or silica or boron oxide, which alone can melt into a glass body in the combustion, determines the main properties of glass, appropriately called silicate glass or borosilicate glass.(2): the main ingredients of soda soda or salt and mirabilite into glass is sodium, they can with silica sand and other acidic oxides formed in the fusible salt calcination, the fluxing action, the glass is easy to mold. But if the content is too much, the thermal expansion rate of glass will increase, and the tensile strength will decrease.(3) limestone, dolomite, feldspar, etc.: the main component of limestone introduced into glass is calcium oxide, which enhances the chemical stability and mechanical strength of glass. But the content is too much, which makes the glass break and reduce the heat resistance.As a raw material for introduction of Magnesium Oxide, dolomite can improve the transparency of glass, reduce thermal expansion and improve water resistance.Feldspar, as a raw material for introduction of alumina, can control the melting temperature and increase durability. In addition, potassium feldspar can also provide components, improve the thermal properties of glass.(4) broken glass: Generally speaking, not all new materials are used in the manufacture of glass, but the broken glass of 15%--30%.

- Q:What kind of raw material does glass form? What is the general smelting process?

- Before people made of glass which has a lot of people use a lot of bubbles, there is no way to take out that European countries made out of glass without bubbles, other countries about the scary, stirring

- Q:What are the materials for car windshields? Is there anything different than ordinary glass?

- Area of toughened glass is a new type of toughened glass, it through special treatment, can impact rupture, crack the glass can still maintain a certain clarity, ensure the driver's field of vision is not affected, has been widely used in the front windshield of the car, but with the demand for vehicle safety and the car environment continues to improve, with the safety performance of laminated glass with good heat insulation and sound insulation performance has gradually become the mainstream of the front windshield.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Safety Clear Tempered Laminated Glass Factory Price For stairs/floor/balustrade Glass

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products