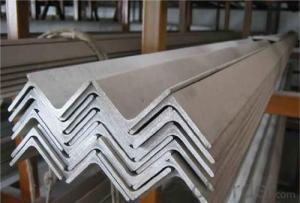

Stainless Steel Angle Iron

Stainless Steel Angle Iron Related Searches

Best Paint For Stainless Steel Paint For Galvanized Steel Steel Frames For Furniture Self Tapping Screws For Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Paint For Stainless Steel Stainless Steel For Bbq Step Bit For Stainless Steel Sponge For Stainless SteelHot Searches

Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Used Metal Folding Chairs For Sale Large Metal Containers For Sale Metal Shop Cabinets For Sale Metal Shipping Crates For Sale Solar Inverter Price In China Best Solar Inverter In China Solar Inverter Price In Dubai Solar Inverter Price In Uae Solar Inverter Price In Kenya Solar Inverter Price In Kerala Solar Inverter Price In Ghana Solar Inverter Price In Nepal Solar Inverter Price In Ksa Fiber Sheet Price In India Fiber Roofing Sheets Price In Pakistan pvc pipe manufacturers in usa Types Of Scaffolding In Construction PdfStainless Steel Angle Iron Supplier & Manufacturer from China

Okorder.com is a professional Stainless Steel Angle Iron supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Stainless Steel Angle Iron firm in China.Hot Products

FAQ

- Yes, stainless steel angles can be used in transportation industries. Stainless steel is known for its durability, corrosion resistance, and high strength-to-weight ratio, making it an ideal material for various applications in the transportation sector. Stainless steel angles can be used in the construction of vehicles such as cars, trucks, trains, and ships, as well as in the fabrication of aerospace components. They are commonly employed in structural frames, chassis, brackets, and supports, providing stability, strength, and longevity to the transportation infrastructure. Additionally, stainless steel angles are also used in the manufacturing of storage systems, racks, and containers for transportation purposes, ensuring the safe transportation of goods and materials. Overall, stainless steel angles are versatile and reliable components that contribute to the efficiency, safety, and durability of transportation industries.

- Stainless steel angle performs exceptionally well in high-humidity environments due to its corrosion-resistant properties. The chromium content in stainless steel forms a protective layer on the surface, preventing moisture from reaching the underlying metal. This protective layer allows the stainless steel angle to withstand prolonged exposure to high humidity without rusting or corroding, making it an ideal choice for applications in such environments.

- Yes, stainless steel angles are suitable for furniture manufacturing. Stainless steel is known for its durability, corrosion resistance, and aesthetic appeal, making it an ideal material for furniture. Stainless steel angles provide structural support and stability, making them a reliable choice for various furniture applications.

- Yes, stainless steel angles are highly resistant to atmospheric corrosion due to their chromium content, which forms a protective oxide layer on the surface, preventing rust and corrosion.

- Various purposes in construction make stainless steel angles widely used. One primary application of stainless steel angles is for providing structural support in construction. These angles are commonly utilized as beams, lintels, and columns to ensure buildings and infrastructure have the necessary strength and stability. The excellent corrosion resistance and high durability of stainless steel angles make them preferred in construction. They can withstand harsh environmental conditions, both indoors and outdoors. Even in highly corrosive environments like coastal regions or chemical plants, stainless steel angles maintain their structural integrity due to their corrosion resistance. Apart from structural support, stainless steel angles also have applications in architectural designs. They add aesthetic appeal to building facades, handrails, and staircases, serving as decorative elements. The versatility of stainless steel angles allows architects and designers to create unique shapes and structures that enhance the visual appeal of a construction project. Moreover, stainless steel angles are easy to fabricate and install, making them valuable in construction. They can be cut, drilled, welded, and shaped according to specific project requirements. This flexibility simplifies the construction process and allows for cost-effective customization. In conclusion, stainless steel angles are crucial in construction as they provide structural support, architectural design elements, and durability. Their corrosion resistance, versatility, and ease of fabrication make them a preferred choice in various construction projects, ranging from residential buildings to commercial complexes and industrial facilities.

- Stainless steel angles have excellent fire-resistant properties due to their composition and structural characteristics. Stainless steel is an alloy made primarily of iron, chromium, and other elements like nickel and molybdenum. The high chromium content in stainless steel creates a passive oxide layer on the surface, which acts as a protective barrier against corrosion and heat. When exposed to fire, stainless steel angles exhibit remarkable resistance to oxidation and maintain their structural integrity. They have a high melting point, typically around 1400-1450 degrees Celsius, which means they can withstand extreme temperatures without deforming or losing strength. This makes stainless steel angles highly suitable for applications in fire-prone environments, such as industrial facilities, construction sites, and residential buildings. Furthermore, stainless steel angles have a low thermal conductivity, which means they do not conduct heat as readily as other materials like aluminum or carbon steel. This property helps prevent the spread of heat and flames, making stainless steel angles an effective fire barrier. Another advantage of stainless steel angles in fire-resistant applications is their resistance to thermal expansion. When exposed to high temperatures, stainless steel angles exhibit minimal expansion and contraction, ensuring that they maintain their structural stability even under extreme thermal conditions. In summary, stainless steel angles possess exceptional fire-resistant properties due to their high melting point, resistance to oxidation, low thermal conductivity, and minimal thermal expansion. These properties make stainless steel angles a reliable choice for various fire-related applications where safety and durability are paramount concerns.

- Stainless steel angles are indeed applicable in the manufacturing of sports equipment. With its desirable properties such as high strength, corrosion resistance, and durability, stainless steel has become a favored option in various industries, including sports equipment manufacturing. In constructing different sporting equipment like goal posts, basketball hoops, tennis rackets, golf club heads, and gym equipment, stainless steel angles serve as reliable structural support capable of enduring the demanding requirements of sports activities. Moreover, stainless steel's easy maintenance and cleaning are crucial factors for sports equipment frequently exposed to sweat, dirt, and moisture. In conclusion, the strength, corrosion resistance, and longevity of stainless steel angles make them an appropriate material choice for producing sports equipment.

- Depending on the specific application and requirements, stainless steel angles can have different edge conditions. Some common edge conditions include: 1. Mill Edge: When stainless steel angles are produced, they typically have a slightly rough and uneven finish, which is the standard edge condition. 2. Trimmed Edge: To create straight and smooth edges, the mill edges of the stainless steel angles can be trimmed or squared off. This enhances the aesthetic appeal and eliminates sharp edges. 3. Deburred Edge: Sharp or rough edges can be removed from the stainless steel angles through a process called deburring. This involves filing or grinding the edges to create a smooth and rounded finish, making them safer to handle and reducing the risk of injury. 4. Beveled Edge: An angle can be cut or ground along the edge of the stainless steel angle to create a beveled edge. This edge condition is commonly used in applications where a seamless transition or joint is required, such as in architectural designs or for aesthetic purposes. 5. Rounded Edge: In this edge condition, the edges of the stainless steel angles are rounded off. This is often done to improve safety and reduce the risk of injury, especially in applications where there is frequent contact with the angles, such as handrails or guardrails. 6. Chamfered Edge: To facilitate easier installation or prevent damage to other components during assembly, a beveled edge at a specific angle can be cut or ground on the corners or edges of the stainless steel angles. These various edge conditions for stainless steel angles offer benefits in terms of safety, aesthetics, ease of installation, and overall functionality in different applications. The choice of edge condition depends on the specific requirements and considerations of the project or application at hand.