Galvanized Steel Profile/Metal Stud and Track

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 g/m

- Supply Capability:

- 300000 g/m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

purlin and wall beam of steel structure building

The C-shaped purlins have excellent anti-bending property and are easy to install. They are widely used as the supporter of roof and wall in large-scale and mid-scale construction, such as factory, warehouse, garage, exhibition center, cinema, theatre, garden and so on.

Product Advantages:

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized stee strip zinc coating is 80-180g/m2.

3.Warm sales in Middle East , Africa , Australia, Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services.

4. The specification can follow up customer requirments.

5. Advanced equipment can make sure exactly size, high quality products.

Main Product Features:

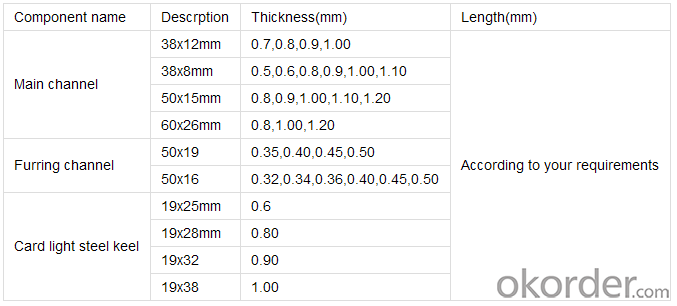

Material

Galvanised steel

Zine Coated Level

60g~270g g/m2 (depends on the customer's request)

Thickness

0.35~1.20mm

Length:

2000mm, 2700mm, 2800mm, 2900mm, 3000mm, 3600mm

Product Specifications:

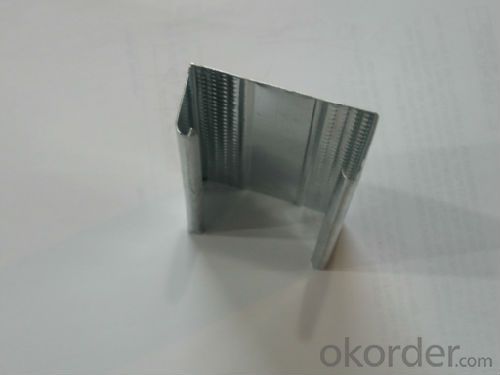

Images:

- Q:How to construct double - sided double gypsum board partition wall

- Vertical keel sub-file: According to the location of the wall defense door openings, in the installation of the top keel, according to the specifications of the panel panel width, sub-file size 450mm, less than the modulus of the file should avoid the first box Plate position, so that the edge of the gypsum cover panel is not out of the box. Installation of horizontal card keel: According to the design requirements, wall height greater than 3m should be added to the horizontal card retaining keel, mining core pulling rivets or screws tied to fixed

- Q:How to fix the middle of the light steel keel to the roof and the ground, the keel has a joint?

- If it is looking for decoration workers to do, then they are professional. Under normal circumstances is the use of surge tube and self-tapping screws fixed. (There are other ways). Keel specifications a lot, generally long after the increase in joints. What specifications of the keel with what specifications of the joints. Not common.

- Q:Light steel keel gypsum board partition wall construction practices and construction process What is the difference?

- The practice is to first play on the ground and shed on the corner keel must be vertical after the installation of the main keel times the keel installed in the plaster board plaster brush latex paint difference is stronger than the keel cost is higher than the wood keel

- Q:What are the consequences of installing a hanging cabinet on gypsum board wall?

- You say the situation gave me the feeling you installed the location is not gypsum board wall, may be light brick. Can drill with the impact of drilling and the installation of the expansion of the bolt, not gypsum board wall can do - where the gypsum board wall can withstand the impact of the impact of drilling? Chopsticks can be used to drill the gypsum board wall, how could the expansion bolts? Or is the gypsum board wall inside filled with light brick, otherwise it is impossible to do so. In addition, if the impact of the drilling position is keel, then the impact of the impact of drilling, will issue a big voice, and the whole wall has a shock; if the keel is light steel keel, it will soon play Wear, but it is possible to make the fixed gypsum board screws off, causing the gypsum board loose; if it is wood keel, the impact drill can play the wood slag to - this can be seen. Based on the above analysis, I think your cabinet can be fixed, but only four screws are too little. As to how much weight? This is difficult to determine. But generally placed some clothes or slightly heavier things, should be no problem.

- Q:Light steel keel with what screws fixed gypsum board

- That is, depending on the general distance from the general self-tapping screw teeth to be larger. Fast teeth screws are generally used for wood, aluminum and other materials, in the role of power tools, you can quickly into the material inside their own. Because the fast tooth screws are mostly self-attack class, will not use the nut. Ordinary screw general mechanical screws, can support the nut. ??? Mechanical screws and self-tapping screws are very different in tooth pitch.

- Q:Light steel keel wall gypsum board seams how to deal with? Including smallpox

- First with gypsum board filling material to fill the gap, in the bandage, and then touch the strap on the 2 - 3 layer of joints, with sandpaper tied on the line friends

- Q:Can my light steel keel ceiling withstand the weight?

- Light steel keel with superior and non-superior type. 50 light steel keel is not on the man's 50mm * 19mm * 0.5mm man's 50mm * 20mm * 0.6mm main keel man 60 * 27 * 1.2. In addition, the keel of the outer keel does not require less than 600 * 600, and the mandarin keel is usually not less than 400 * 400 according to the load. Compare your material to see what specifications the keel is. Baidu may wish to look at these two types. If it is superior type, there is no problem

- Q:Wood keel can be used to ceiling, can be used to do the wall? Light steel keel can be used in what place?

- Light steel keel level can be used in the ceiling, can also be used in the partition, Wood keel can also be cut off the ceiling can be done.

- Q:How much does it cost to use a light steel keel gypsum board?

- 15 square meters of the wall 15 * 65 = 925 + ordinary door 300 - 400 + installation door hand fee 120 = 1345-1445. But the square is too small, the general companies do not want to do, the fare back and forth have much money.

- Q:Light steel keel wall circuit how to wear pipe

- 1, to C-type vertical keel on the threading hole as the basis, first determine the direction of the upper and lower ends of the keel, try to align the threading hole. Vertical keel length size, should be measured according to the size of the scene. The premise is to ensure that the vertical keel can be along the ground, along the long keel slot slide. 2, light steel wall vertical keel installation spacing, according to the actual width of the panel size and wall structure design may be. 3, vertical keel installed in place, should ensure that the vertical. Door and window openings should be taken double row of vertical keel reinforcement. When the design requirements for the steel connection, the vertical keel and the edge along the top keel of the fixed, the application of self-tapping screws or shaft rivets to connect. sixth,

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Steel Profile/Metal Stud and Track

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 g/m

- Supply Capability:

- 300000 g/m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords