Q235B Steel Angle

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000T/Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Standards: GB,ASTM,BS,AISI,DIN,JIS

2.Material: GB Q235B, Q345B or Equivalent; ASTM A36; EN 10025, S235JR, S355JR; JIS G3192, SS400; SS540.

3.Length:6m,9m,12m

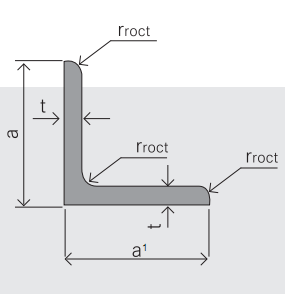

4.Sizes:

|

Sizes: 25mm-250mm | ||

|

a*t | ||

|

25*2.5-4.0 |

70*6.0-9.0 |

130*9.0-15 |

|

30*2.5-6.6 |

75*6.0-9.0 |

140*10-14 |

|

36*3.0-5.0 |

80*5.0-10 |

150*10-20 |

|

38*2.3-6.0 |

90*7.0-10 |

160*10-16 |

|

40*3.0-5.0 |

100*6.0-12 |

175*12-15 |

|

45*4.0-6.0 |

110*8.0-10 |

180*12-18 |

|

50*4.0-6.0 |

120*6.0-15 |

200*14-25 |

|

60*4.0-8.0 |

125*8.0-14 |

250*25 |

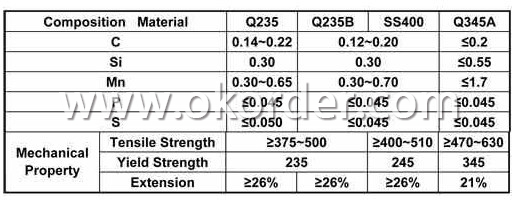

5.Material Specifications:

Usage & Applications of Q235B Steel Angle

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of Q235B Steel Angle

1.Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2.With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

- Q:How do you prevent steel angles from vibrating?

- There are several ways to prevent steel angles from vibrating: 1. Damping materials: Applying damping materials such as rubber pads, neoprene, or foam between the steel angles and the structure they are attached to can help absorb and dissipate vibrations. 2. Structural modifications: Reinforcing the steel angles by adding additional supports or bracing can help reduce vibrations. By increasing the stiffness and rigidity of the structure, the tendency for vibrations to occur can be minimized. 3. Mass modification: Adding additional mass to the steel angles can help stabilize them and reduce vibrations. This can be achieved by attaching weight plates or heavier components to the angles. 4. Tensioning: Applying tension to the steel angles can help reduce vibrations by increasing their natural frequency and stiffness. This can be done by tightening bolts or using tensioning devices. 5. Vibration isolation: Using vibration isolation techniques, such as mounting the steel angles on rubber isolators or spring mounts, can help isolate them from the surrounding structure and minimize vibration transmission. 6. Resonance avoidance: Identifying and avoiding the natural frequencies of the steel angles is crucial in preventing vibrations. By analyzing the structural dynamics and adjusting the design or operational conditions, resonance can be avoided, reducing the chances of vibrations. 7. Regular maintenance: Regularly inspecting and maintaining the steel angles can help identify any issues or potential sources of vibrations. This includes checking for loose connections, corrosion, or any signs of wear and tear that could contribute to vibration problems. It is important to note that the specific method(s) chosen to prevent steel angles from vibrating will depend on various factors, including the application, structural design, and environmental conditions. Consulting with a structural engineer or vibration specialist is recommended to ensure the most effective and appropriate solution is implemented.

- Q:Can steel angles be used in bridge construction?

- Yes, steel angles can definitely be used in bridge construction. Steel angles, also known as L-shaped structural steel, are commonly used as cross-sectional supports in bridge construction. They are particularly useful for providing stability, strength, and rigidity to bridge structures. Steel angles are versatile and can be used for various bridge components such as beams, trusses, and bracing systems. They are often welded or bolted together to form structural connections, ensuring the integrity and load-carrying capacity of the bridge. Steel angles offer several advantages in bridge construction, including their high strength-to-weight ratio, durability, and resistance to corrosion. Overall, steel angles are a reliable and widely used component in the construction of bridges.

- Q:How do you determine the plastic section modulus of a steel angle?

- In order to determine the plastic section modulus of a steel angle, a specific calculation process must be followed. The plastic section modulus (Z) is used to assess the ability of a cross-section to resist plastic bending and is commonly employed in structural engineering to analyze the strength and stability of members. To calculate the plastic section modulus of a steel angle, it is necessary to know the dimensions of the angle cross-section, including the length of the legs and the thickness of the steel. Once these measurements are obtained, the following steps can be carried out: 1. The centroid of the angle cross-section must be identified. This centroid serves as the geometric center of the shape and is a crucial reference point for calculating the plastic section modulus. By determining the average of the coordinates of the vertices, the centroid can be found. 2. The moment of inertia (I) needs to be calculated. The moment of inertia provides a measure of how the area is distributed around the centroid. It can be determined by summing the individual moments of inertia for each component of the cross-section. For a steel angle, the moment of inertia can be calculated using standard formulas or tables. 3. The plastic section modulus (Z) must be determined. The plastic section modulus is directly related to the moment of inertia. It can be computed by dividing the moment of inertia (I) by the distance from the centroid to the outermost fiber of the section. This distance, known as the distance to the extreme fiber (c), is typically equal to half the thickness of the angle. The formula to calculate the plastic section modulus (Z) is Z = I / c. 4. The values obtained for the moment of inertia (I) and the distance to the extreme fiber (c) should be substituted into the formula to calculate the plastic section modulus (Z). By following these steps, the plastic section modulus of a steel angle can be determined. This parameter is crucial for assessing the structural behavior and design of steel angles, particularly when subjected to bending loads.

- Q:How do you determine the resistance to lateral-torsional buckling of a steel angle?

- To determine the resistance to lateral-torsional buckling of a steel angle, several factors need to be considered. The resistance to lateral-torsional buckling is primarily influenced by the geometric properties of the angle section, the material properties of the steel, and the boundary conditions of the member. 1. Geometric properties: The critical geometric properties that affect the resistance to lateral-torsional buckling are the length, width, thickness, and the slenderness ratio of the angle section. The slenderness ratio is the ratio of the length to the radius of gyration of the section and is a measure of the member's stability. Higher slenderness ratios indicate a higher susceptibility to lateral-torsional buckling. 2. Material properties: The resistance to lateral-torsional buckling also depends on the material properties of the steel angle, such as its yield strength, modulus of elasticity, and the shape of the stress-strain curve. These properties determine the capacity of the steel angle to withstand bending and twisting moments without buckling. 3. Boundary conditions: The boundary conditions of the steel angle, including the type of support and the loading conditions, significantly affect its resistance to lateral-torsional buckling. The type of support, such as simply supported or fixed, determines the degree of rotational and translational constraints on the member. Similarly, the applied loads, such as point loads, distributed loads, or moments, determine the bending and twisting moments acting on the angle section. To determine the resistance to lateral-torsional buckling, engineers usually refer to relevant design codes and standards, such as the American Institute of Steel Construction (AISC) Manual or Eurocode. These codes provide design formulas and tables that consider the geometric properties, material properties, and boundary conditions to calculate the critical moment and the corresponding resistance to lateral-torsional buckling for the steel angle. Additionally, finite element analysis (FEA) software or other advanced computer simulations can be employed to obtain more accurate results by considering complex loadings and boundary conditions.

- Q:Are steel angles suitable for high-temperature applications?

- No, steel angles are not suitable for high-temperature applications. Steel angles are typically made from carbon steel, which starts to lose its strength and structural integrity at elevated temperatures. At high temperatures, carbon steel undergoes a process called thermal expansion, where it expands and becomes weaker. This can lead to deformations and structural failures in the steel angles. For high-temperature applications, materials such as stainless steel or alloys with higher heat resistance, such as Inconel or Hastelloy, are more suitable. These materials can withstand higher temperatures without significant loss of strength and structural stability.

- Q:Can steel angles be drilled or machined?

- Drilling or machining steel angles is indeed possible. Their strength and durability make them popular in the construction and manufacturing sectors. Creating holes or shaping them to specific sizes is easily achievable through drilling or machining. However, it is crucial to employ suitable tools and techniques due to their tough composition, necessitating the use of high-speed drilling or machining equipment. Moreover, employing lubricants or coolant during the process can minimize friction and heat accumulation, resulting in a seamless and efficient operation.

- Q:How do steel angles perform in corrosive environments?

- Steel angles perform well in corrosive environments due to their high resistance to corrosion. The presence of alloying elements such as chromium, nickel, and molybdenum in the steel composition enhances its ability to withstand corrosion caused by moisture, chemicals, and other corrosive agents. Additionally, the angles can be further protected through coatings or treatments, such as galvanization or painting, to provide an added layer of defense against corrosion.

- Q:How do you connect steel angles together?

- Steel angles can be connected together by various methods such as welding, bolting, or using steel angle brackets.

- Q:What are the different types of steel angles used in fencing and gates?

- There are several different types of steel angles that are commonly used in fencing and gates. One of the most common types is the equal angle, also known as L-shaped angle. This type of angle has equal length sides and is commonly used for vertical and horizontal bracing in fencing and gates. Another type is the unequal angle, which has one longer side and one shorter side. This type of angle is often used for diagonal bracing in fencing and gates, as it provides additional strength and stability. There is also the rounded edge angle, which has rounded edges instead of sharp corners. This type of angle is often used in fencing and gates to reduce the risk of injury, as the rounded edges are less likely to cause cuts or other accidents. Additionally, there are slotted angles, which have pre-drilled holes along the length of the angle. These holes allow for easy attachment of fencing and gate components, such as panels or hinges. Finally, there are galvanized angles, which have been coated with a layer of zinc to protect against rust and corrosion. This type of angle is ideal for outdoor fencing and gates, as it provides long-lasting durability and resistance to the elements. Overall, the different types of steel angles used in fencing and gates offer various benefits in terms of strength, stability, safety, ease of installation, and resistance to rust and corrosion. The specific type of angle used will depend on the specific requirements and preferences of the fencing or gate project.

- Q:Can steel angles be used for manufacturing machinery?

- Indeed, the utilization of steel angles is viable for the production of machinery. In the construction sector, steel angles are frequently employed as structural elements owing to their robustness, resilience, and cost-effectiveness. In the realm of machinery manufacturing, steel angles find utility in a multitude of ways, encompassing framing, support structures, brackets, and mounting components. They bestow stability and rigidity upon the machinery, thereby ensuring its structural integrity. Moreover, steel angles facilitate the welding, bolting, or riveting processes with ease, permitting flexible and efficient fabrication techniques. By and large, steel angles represent a versatile and dependable choice for the manufacturing of machinery.

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei, China |

| Year Established | 2003 |

| Annual Output Value | Above US$ 500 Million |

| Main Markets | Southeast Asia; middle east; South Korea; Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 30%-45% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM service offered |

| Product Price Range | high; average |

Send your message to us

Q235B Steel Angle

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000T/Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords